Gas supplementation device for ultrahigh-pressure experimental process

An experimental process, ultra-high pressure technology, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as the inability to maintain pressure stability, and achieve the effect of wide applicable pressure range and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

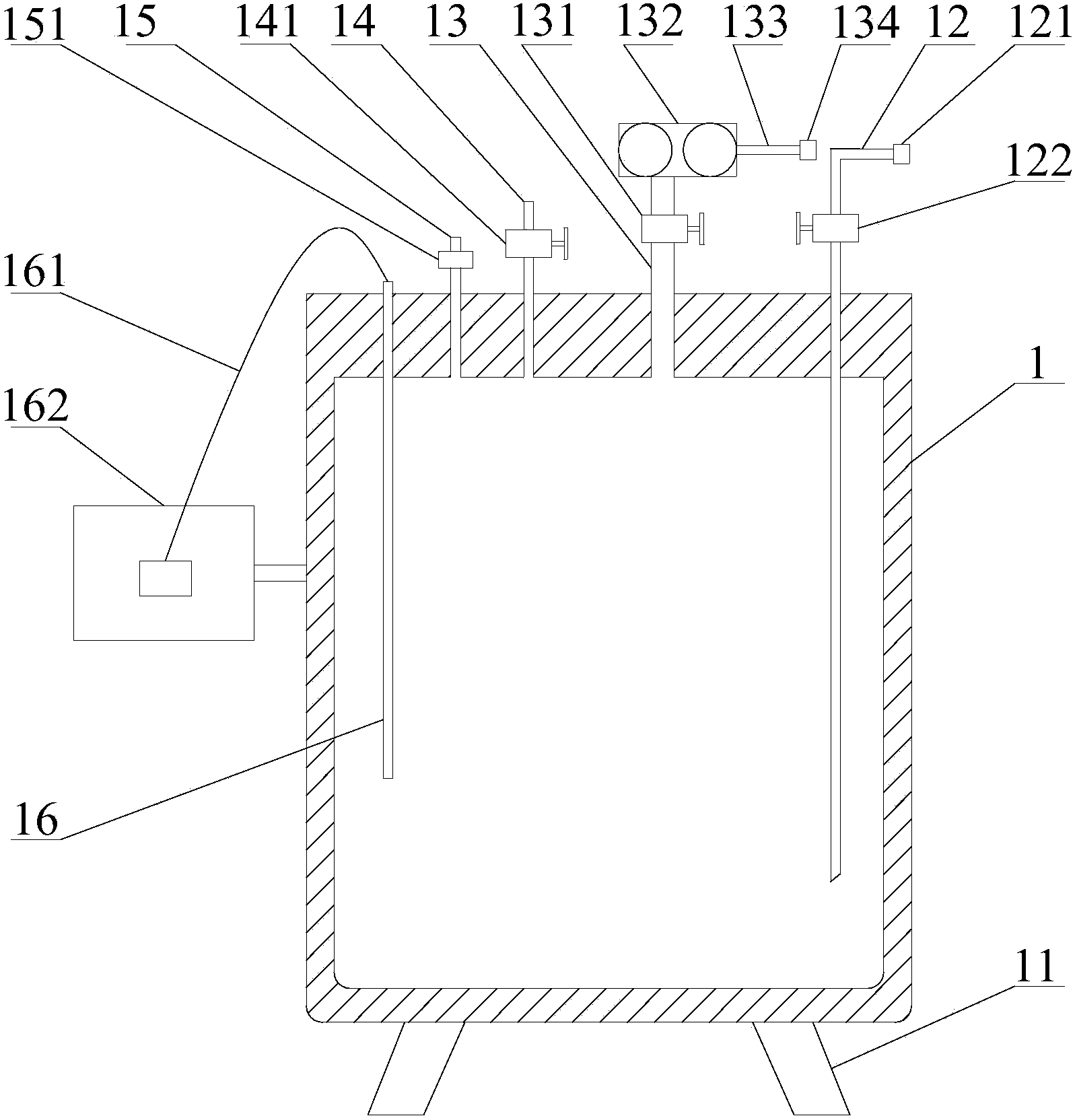

[0017] Such as figure 1 As shown, the device used for gas replenishment during the ultra-high pressure experiment includes: a high-pressure storage tank body 1, a gas input pipe 12, a pressure-stabilizing decompression gauge 132, a gas output pipe 133, and a pressure indicator 162.

[0018] The high-pressure storage tank body 1 is a cylindrical shell with closed upper and lower ends. The high-pressure storage tank body 1 is filled with gas with a pressure higher than the required pressure of the experiment. The high-pressure storage tank body 1 is made of stainless steel, which can avoid the impact of corrosive gases. Corrosion of the kettle body 1 of the high-pressure storage tank.

[0019] The bottom of the kettle body 1 of the high-pressure storage tank is provided with a support frame 11, which is used to support the whole device, and the support frame 11 is made of ordinary carbon steel.

[0020] The top of the high-pressure storage tank kettle body 1 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com