Novel probe for measuring structure surface wind speed in wind tunnel test

A technology for structural surface and wind tunnel testing, which is applied to the measurement of fluid velocity and other directions by using pressure difference, which can solve the problems of low cost, inaccurate wind speed, and non-directionality, and achieve the effects of low cost, convenient processing, and non-directionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

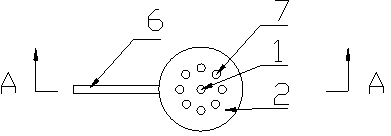

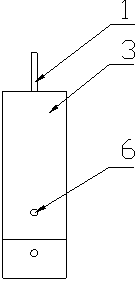

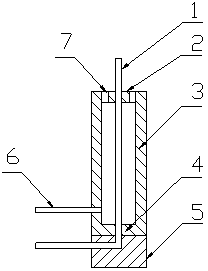

[0014] like Figures 1 to 3 As shown, a novel probe for measuring the surface wind speed of a structure in a wind tunnel test is characterized in that it includes a hollow cylindrical shell 3 and a long pressure-taking tube 1 bent at 90 degrees, and the cylindrical shell 3 The upper end and the lower end are respectively provided with a circular upper end plate 2 and a lower end plate 4 to seal the hollow outlet, the center of the upper end plate 2 and the lower end plate are provided with a central hole, and the edge of the upper end plate 2 is along the edge of the upper end plate 2. The concentric circles are uniformly provided with collection holes 7, the lower end of the cylindrical shell 3 is closely attached to a cylinder 5, and the side wall of the cylindrical shell 3 is horizontally provided with a short pressure-taking hole directly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com