High-speed railway supply arm shunt tripping protection method based on impedance characteristics

An impedance protection, high-speed railway technology, applied in emergency protection circuit devices, electrical components, etc., can solve the problems of high load current of high-speed EMUs, unable to meet the selectivity of protection, unable to identify high-resistance faults at the end, etc. Small, improve the protection sensitivity, the effect of large fixed value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation. The drawings and specific embodiments do not limit the scope of protection claimed by the present invention.

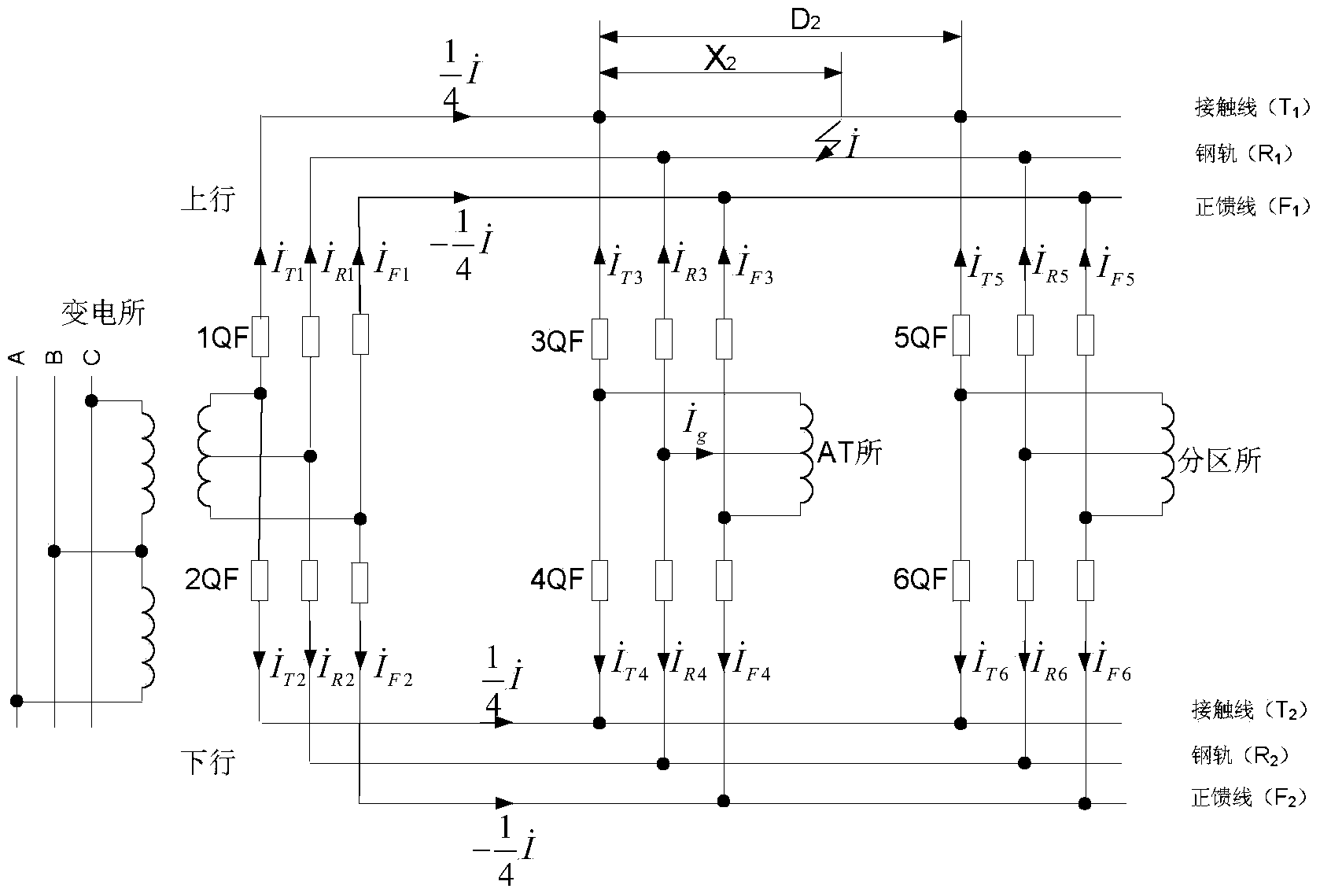

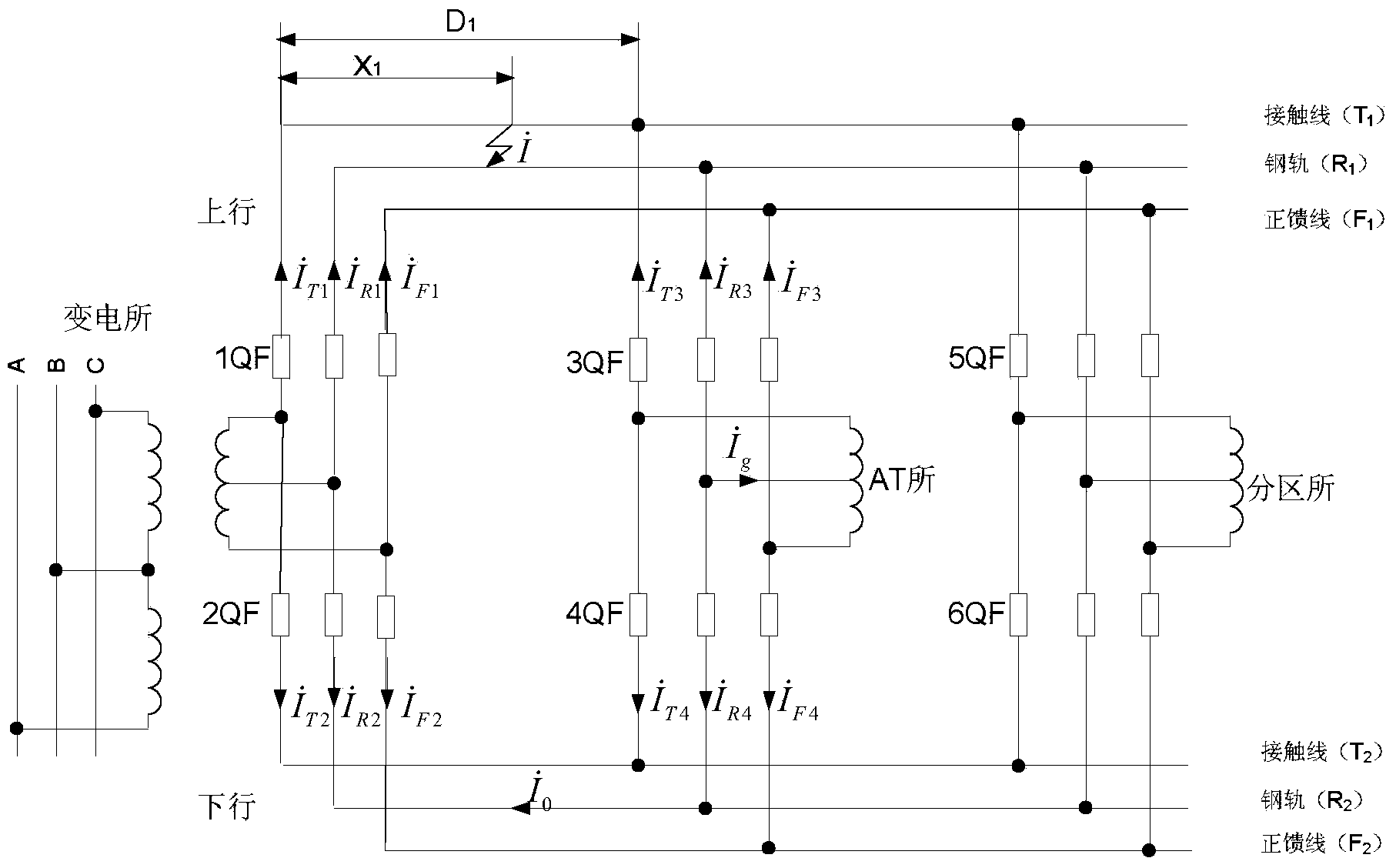

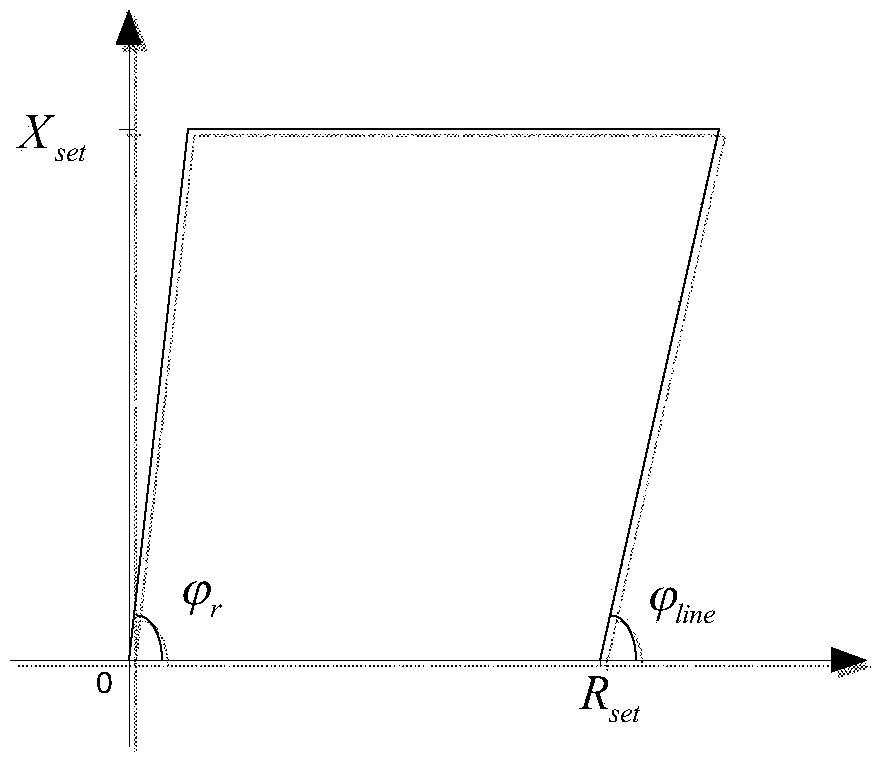

[0029] In an AT traction power supply system, the calculation formula for measuring impedance is generally:

[0030] Z i = U · s I · Ti - I · Fi (Formula 1)

[0031] in, is the ground voltage of the contact line busbar or the ground voltage of the positive feeder busbar, and s is the substation, AT station or divisional station respectively; are the contact line current and the positive fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com