Hot-wind solidification automatic cloth feeding (cloth leading) mechanism

An automatic and cloth-feeding technology, which is applied in the direction of winding strips, sending objects, thin material processing, etc., can solve problems such as difficult operation, affecting production efficiency, and product quality decline, and achieves improved working environment and labor intensity, and equipment Wide range of use and the effect of reducing working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0014] Detailed ways Next, the present invention will be described in detail in conjunction with the accompanying drawings

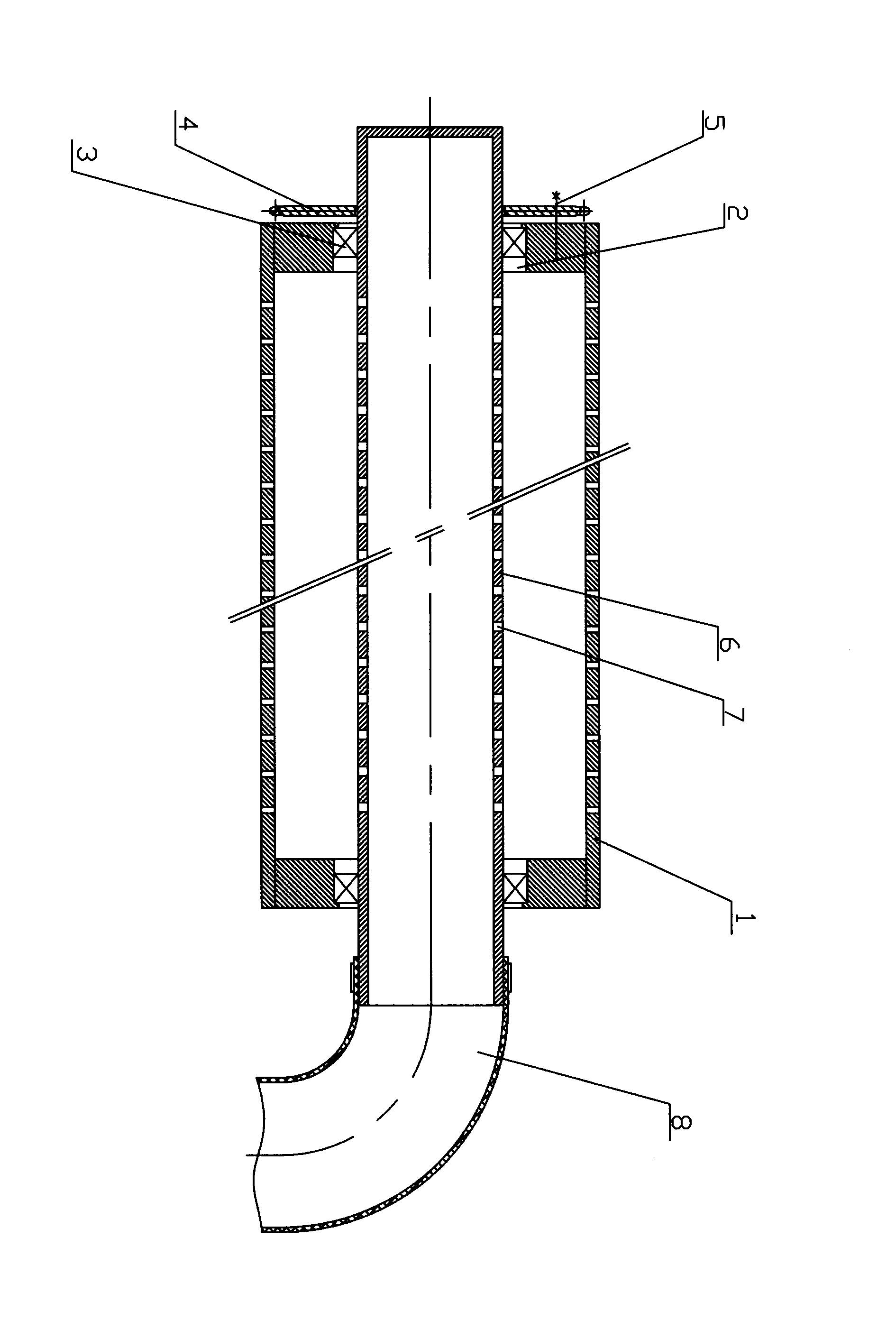

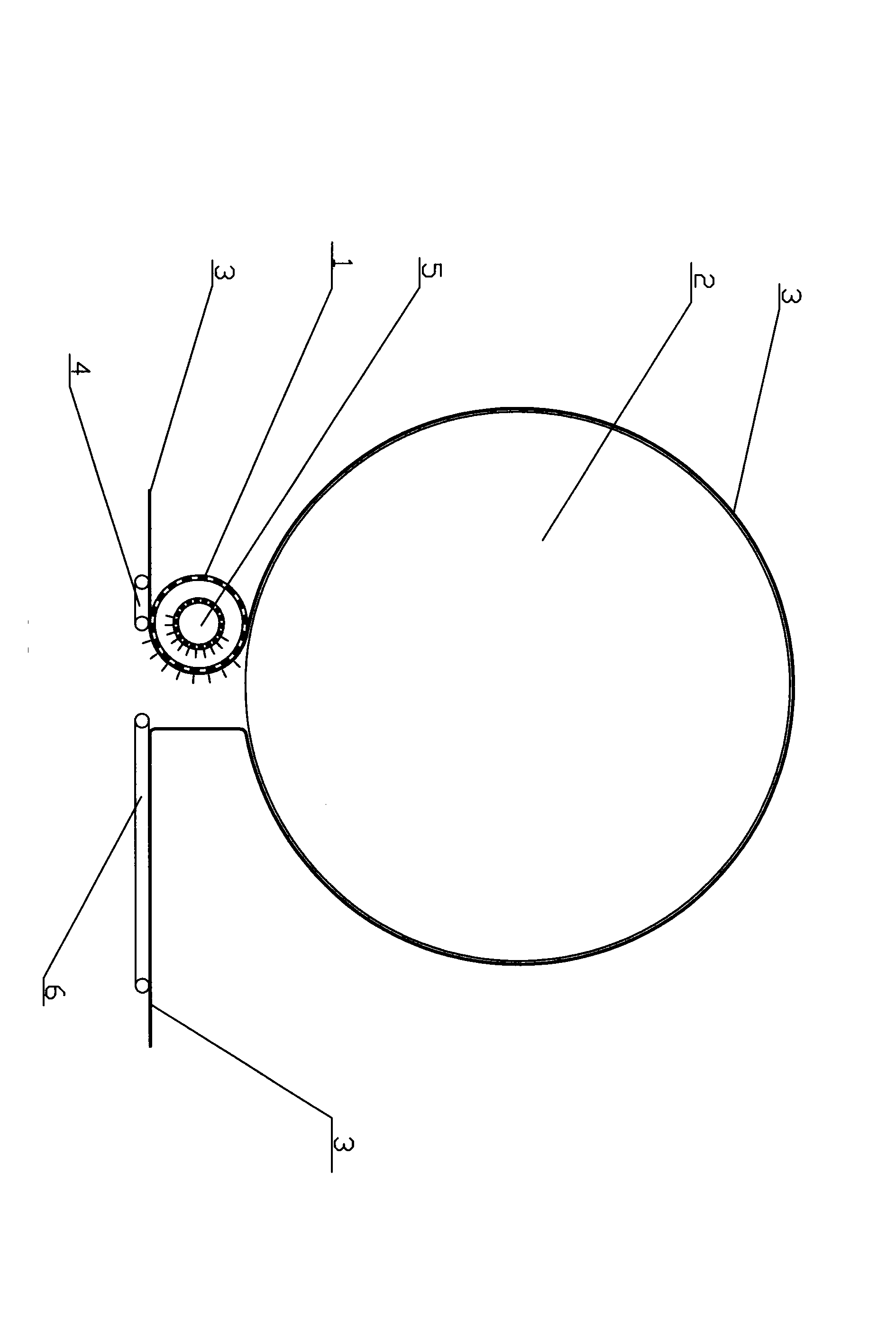

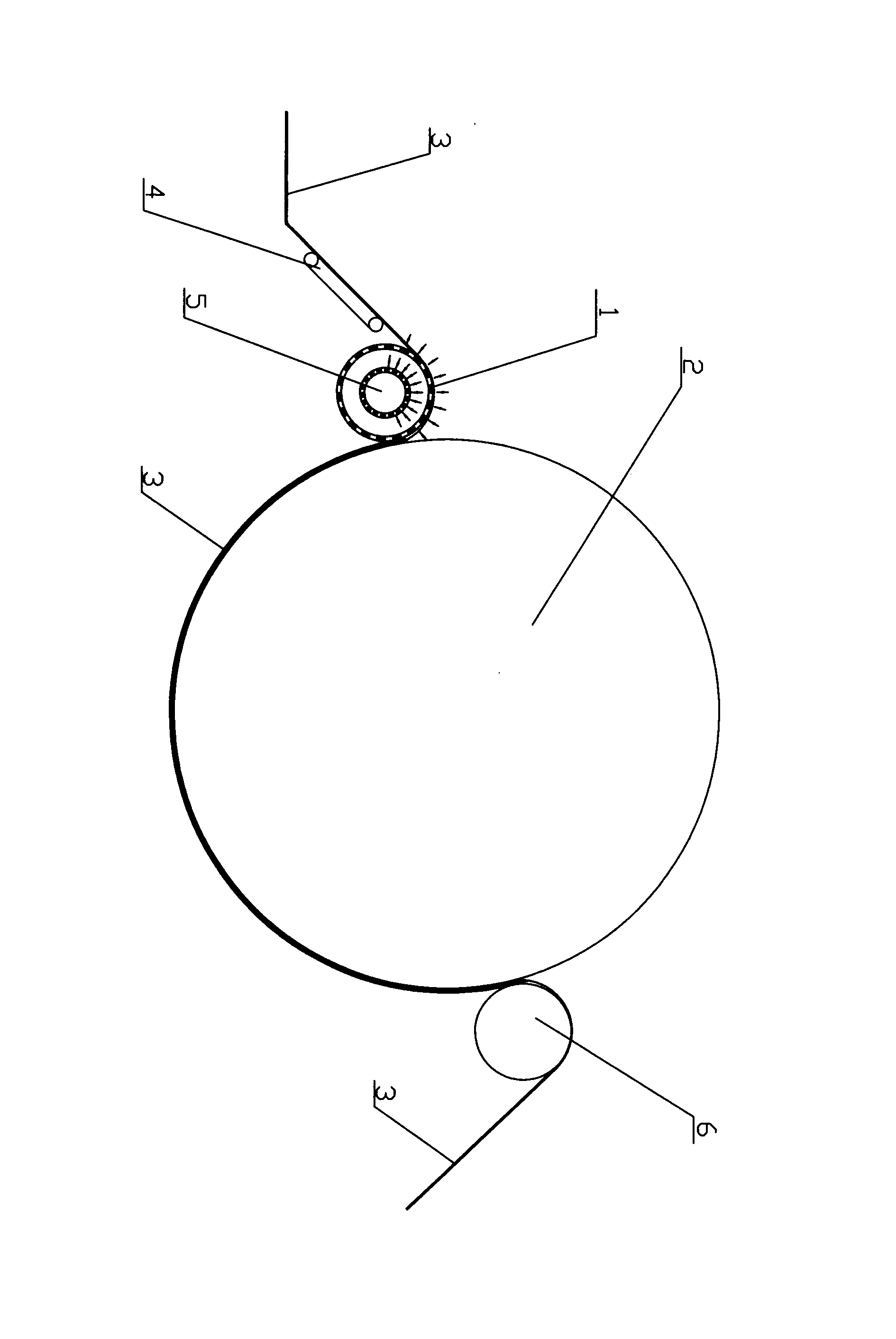

[0015] A hot air consolidation automatic cloth feeding (cloth leading) mechanism, such as figure 1 As shown, the horizontal outer roller 1 is a hollow round roller made of orifice plates, and the middle positions of the plates at both ends of the axial direction are respectively provided with coaxial through holes 2, and bearing seats 3 are respectively fixed in the through holes; the above outer rollers The axial side of the shaft is provided with a transmission gear 4 coaxial with it, and the transmission gear is connected with one side end plate of the outer roller through fastening bolts 5; 6. The inner roller is a hollow round roller with an opening at one end in the axial direction, and its outer peripheral wall is in contact with the bearing of the bearing seat. There are still several through holes on the inner roller, that is, the air suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com