Continuous fiber reinforced thermoplastic flame retardant antistatic composite material and preparation method thereof

A flame-retardant, anti-static, and thermoplastic-enhancing technology, used in textiles and papermaking, etc., can solve the problems of high surface resistance of engineering plastics, easy to generate static electricity, application limitations, etc., to solve impregnation difficulties, improve compatibility, and improve wetting effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

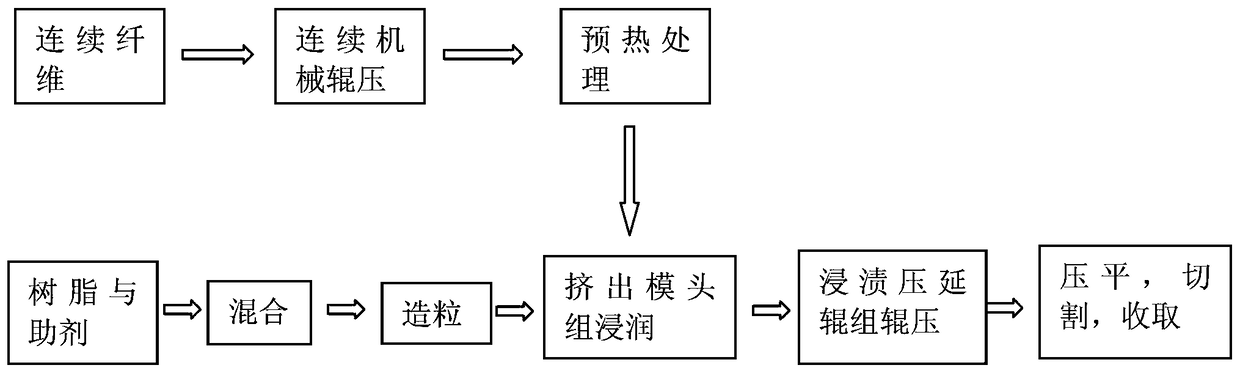

[0057]A continuous fiber reinforced thermoplastic flame-retardant antistatic composite material, the preparation steps of which are as follows figure 1 Shown:

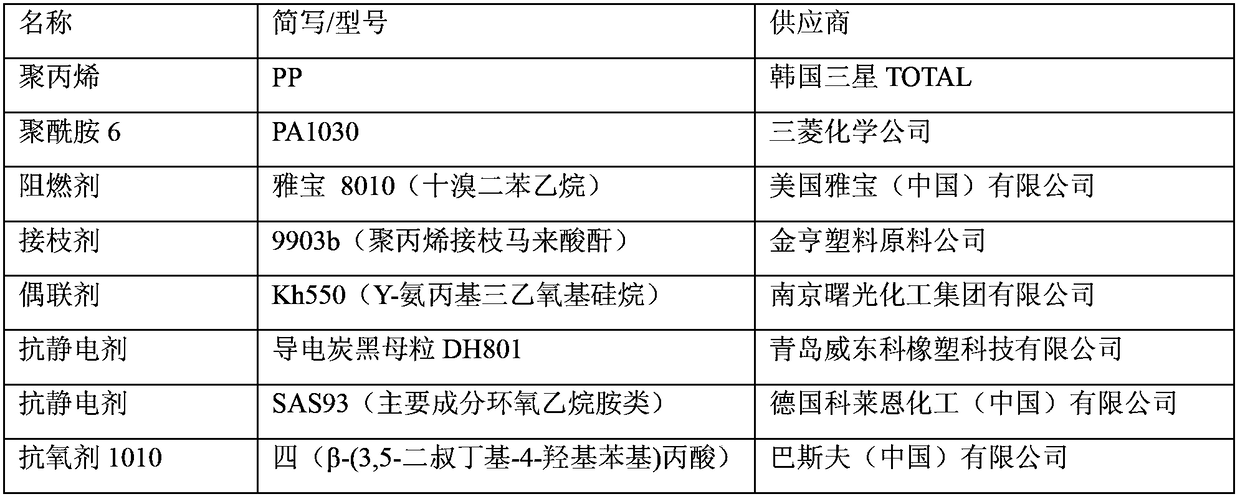

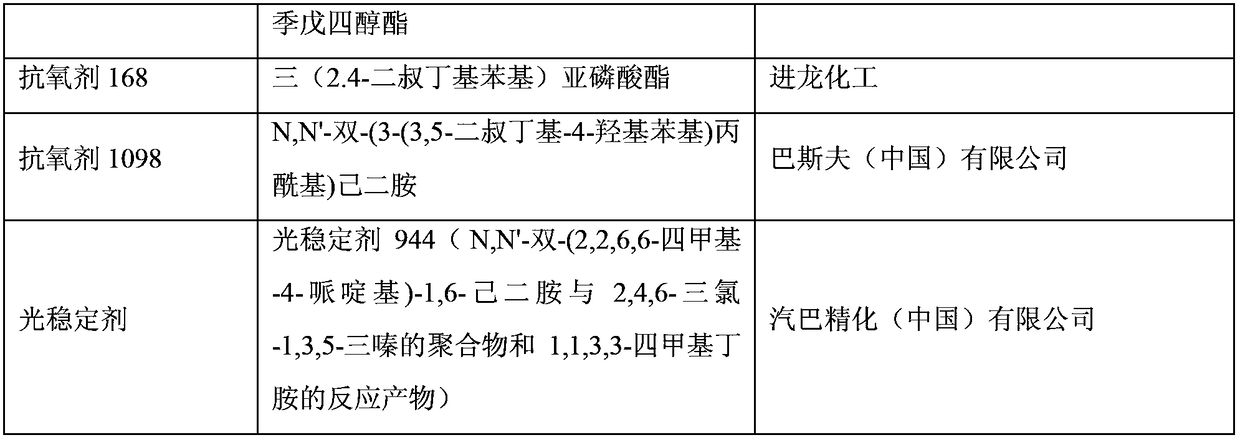

[0058] (1) Weigh 55 parts of polypropylene, 30 parts of flame retardant decabromodiphenylethane, 5 parts of grafting agent 9903b, 10 parts of conductive carbon black, 0.2 parts of antioxidant 168, 0.2 parts of antioxidant 1010, 1 part of light stabilizer 944, 1 part of coupling agent Kh550 parts are fully mixed, extruded and granulated by twin-screw extruder to obtain modified resin.

[0059] (2) The continuous glass fiber is introduced into the fiber spreading system through the textile creel, and the fiber is continuously rolled to adjust the tension, so that the fiber can be stretched and thinned on the original basis, and then preheated by an infrared oven to obtain pretreatment The preheating temperature is 180℃, and the preheating time is 3s. The preheated glass fiber passes through the tension adjustment device...

Embodiment 2

[0065] A continuous fiber reinforced thermoplastic flame-retardant antistatic composite material is prepared according to the following steps:

[0066] (1) Weigh 60 parts of polyamide 6, 30 parts of red phosphorus, 3.5 parts of grafting agent kh550, 0.3 parts of antioxidant 1098, 0.1 part of antioxidant 1010, 1 part of light stabilizer 944, 5 parts of anti-oxidant Static agent SAS93, 3 parts of coupling agent Y-aminopropyltriethoxysilane are fully mixed, extruded and granulated by twin-screw extruder to obtain modified resin;

[0067] (2) The continuous carbon fiber is introduced into the fiber spreading system through the spinning creel, and the carbon fiber is continuously rolled to adjust the tension, so that the fiber can be widened and thinned on the original basis, and then preheated by an infrared oven to obtain the pretreated The preheating temperature is 180°C, and the preheating time is 3-5s. After preheating, the carbon fiber passes through the tension adjustment de...

Embodiment 3

[0073] A continuous fiber reinforced thermoplastic flame-retardant antistatic composite material is prepared according to the following steps:

[0074] (1) Weigh 60 parts by weight of thermoplastic polyamide 1010, 20 parts of flame retardant (tris(2,2-dibromomethyl-3-bromopropyl phosphonate) and 20 parts of resorcinol Bisphosphonic acid ester, 3 parts of grafting agent polypropylene grafted maleic anhydride, 3 parts of coupling agent Y-aminopropyltriethoxysilane, 5 parts of antistatic agent ethylene oxide, antioxidant bis( 0.2 parts of 3,5-tertiary butyl-4-hydroxyphenyl) sulfide and 0.5 parts of light stabilizer phenyl hydroxybenzoate were fully mixed, and extruded and granulated by a twin-screw extruder to obtain Modified resin;

[0075] (2) The continuous fiber (aromatic polyamide fiber) is introduced into the fiber spreading system through the spinning creel, and the fiber is continuously rolled to adjust the tension, so that the fiber can be widened and thinned on the ori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com