Liquid crystal composition

A technology of liquid crystal composition and liquid crystal compound, applied in the direction of liquid crystal materials, chemical instruments and methods, etc., to achieve the effects of high optical power, large transmittance, and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

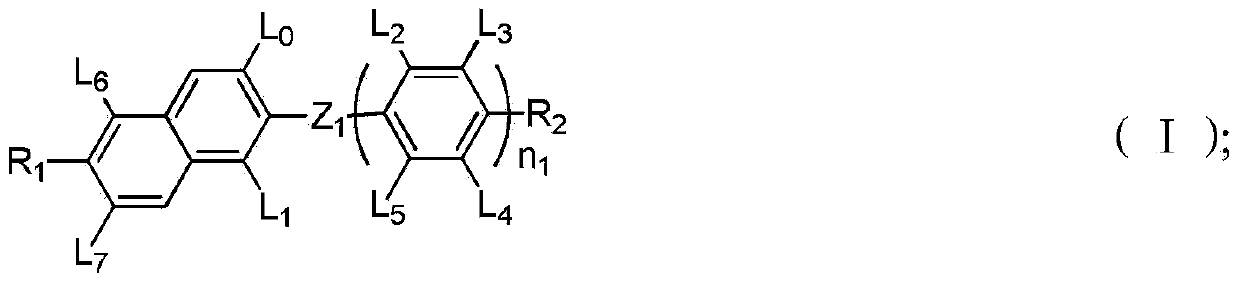

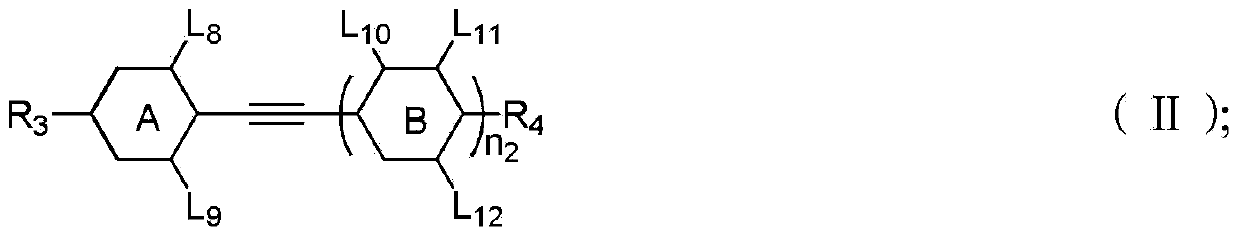

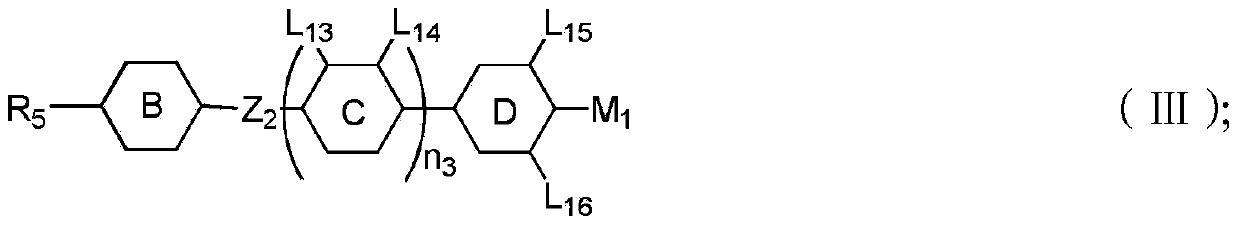

Method used

Image

Examples

Embodiment 1

[0077] According to the method described above, a liquid crystal composition comprising the following components was prepared, and its performance was measured.

[0078]

[0079]

Embodiment 2

[0081] According to the method described above, a liquid crystal composition comprising the following components was prepared, and its performance was measured.

[0082]

[0083]

Embodiment 3

[0085] According to the method described above, a liquid crystal composition comprising the following components was prepared, and its performance was measured.

[0086]

[0087]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com