Liquid crystal composition and liquid crystal display device containing liquid crystal composition

A liquid crystal composition and technology of the composition, applied in the directions of liquid crystal materials, instruments, chemical instruments and methods, etc., can solve the problems of long response time, difficult storage stability at low temperature, low resistivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

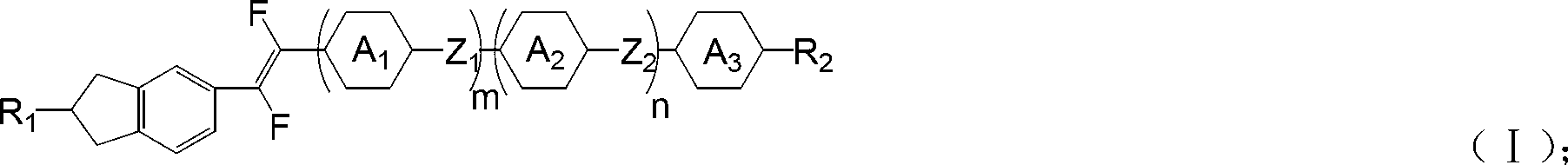

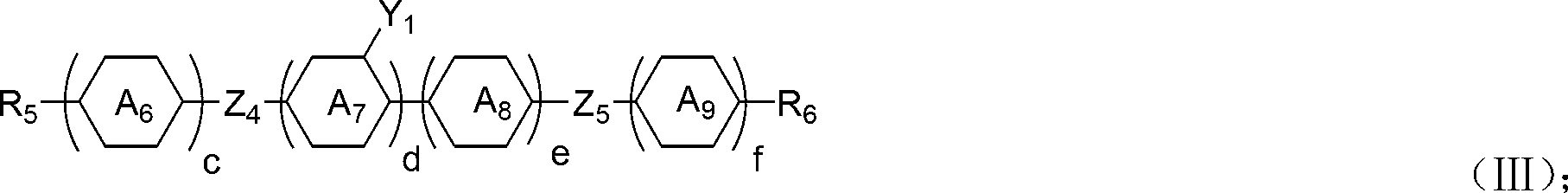

[0082] Preparation of compounds of general formula (I)

[0083] 1) In the solvent tetrahydrofuran, at room temperature, the compound of general formula 1

[0084] (Formula 1)

[0085] with the compound of formula 2

[0086] (Formula 2)

[0087] Under the protection of nitrogen, the catalyst was reacted for 16 hours in the presence of tetrakis (triphenylphosphine) palladium to obtain the compound of general formula 3

[0088] (Formula 3);

[0089] 2) In the solvent tetrahydrofuran, under the protection of nitrogen, at -100 ° C ~ -50 ° C, the compound of the general formula 4

[0090] (Formula 4)

[0091] React with nBuLi to obtain the lithium reagent of general formula 5,

[0092] (Formula 5)

[0093] Then react the lithium reagent with the compound of the general formula 3 to obtain the compound represented by the general formula (I).

[0094] R in the above general formula (general formula 1, general formula 3, general formula 4 and general formula 5) 1 , R...

preparation example

[0096] The synthetic specific process steps of the prepared compound I-8-2 are as follows:

[0097] 1) Synthesis of lithium diisopropylamide (LDA)

[0098] Add 115ml of diisopropylamine and 100ml of tetrahydrofuran (THF) into a 1000ml three-necked flask, under nitrogen protection, add 320ml of n-butyllithium (n-BuLi, 2.4mol / L) dropwise under temperature control at 0°C~-20°C, after dropping, 0 Stir at ~-20°C for 1 hour to prepare LDA.

[0099] 2) Synthesis of trifluorovinyl zinc chloride

[0100]

[0101] Add 53g of anhydrous zinc chloride and 100ml of THF to a 1000ml three-necked bottle, protect it with nitrogen, cool down to -70°C, and feed 54g of 1,1,1,2-tetrafluoroethane gas, and control the temperature from -50°C to -70°C Slowly inject LDA under the liquid surface through the needle tube, and stir for 2 hours after the addition, to obtain trifluorovinyl zinc chloride.

[0102] 3) Synthetic compound of formula 6

[0103] (Formula 6)

[0104] (Formula 7)

[0105...

Embodiment 1

[0129] Prepare the liquid crystal composition of the present invention by each compound listed in Table 3 and the weight percentage, it is filled between the two substrates of the liquid crystal display for performance testing, and the test data are shown in the following table:

[0130] Table 3 liquid crystal composition formula and test performance thereof

[0131]

[0132] By comparing Example 1 and Comparative Example 1, it can be seen that the composition provided by the present invention has suitably high optical anisotropy, suitably high dielectric anisotropy, and a lower threshold voltage, so that the liquid crystal element has superior energy saving properties. Electrical performance, low viscosity, so that it can achieve fast response speed, so it is suitable for notebook computer equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com