Assembling type prefabricated balcony board and balcony support connecting structure

A technology for connecting structures and balcony panels, applied in building structures, buildings, etc., and can solve problems such as loss and cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention will be further described:

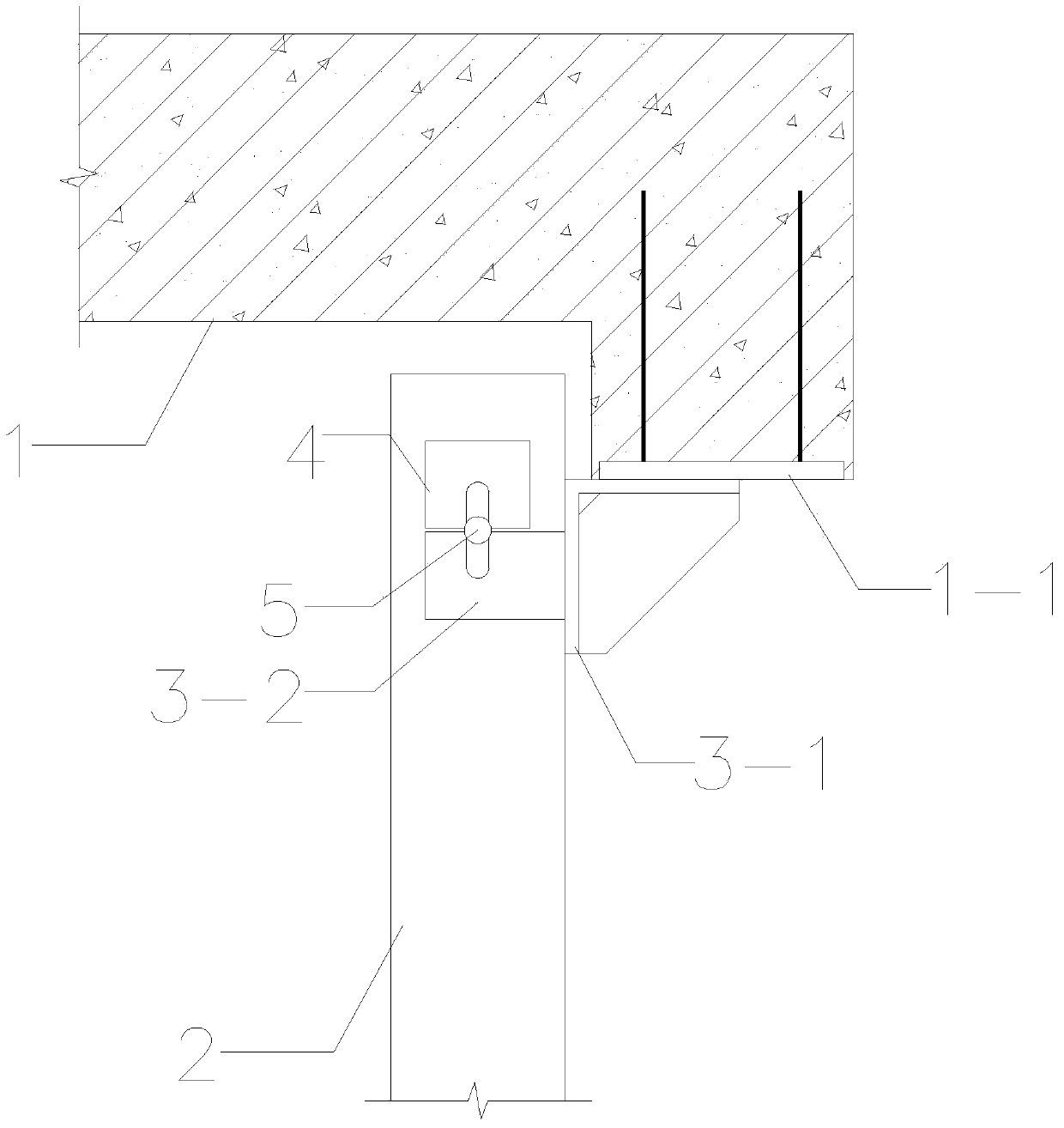

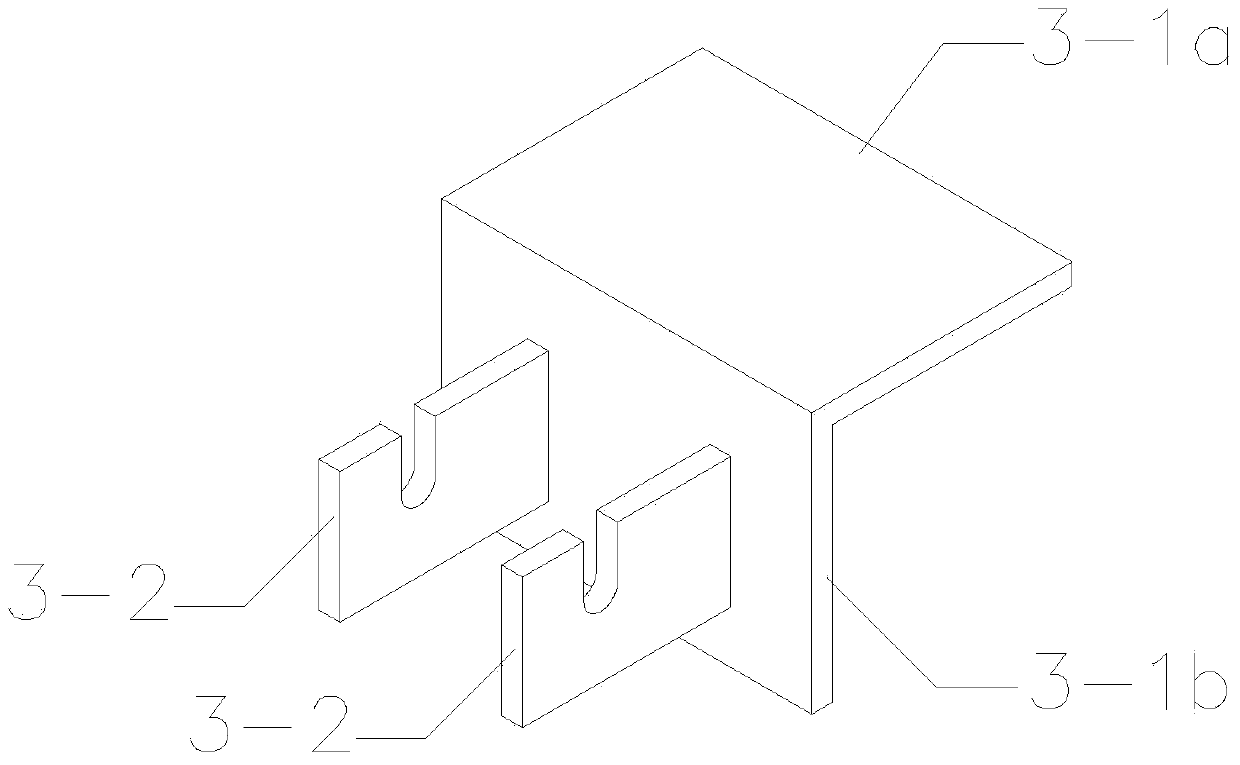

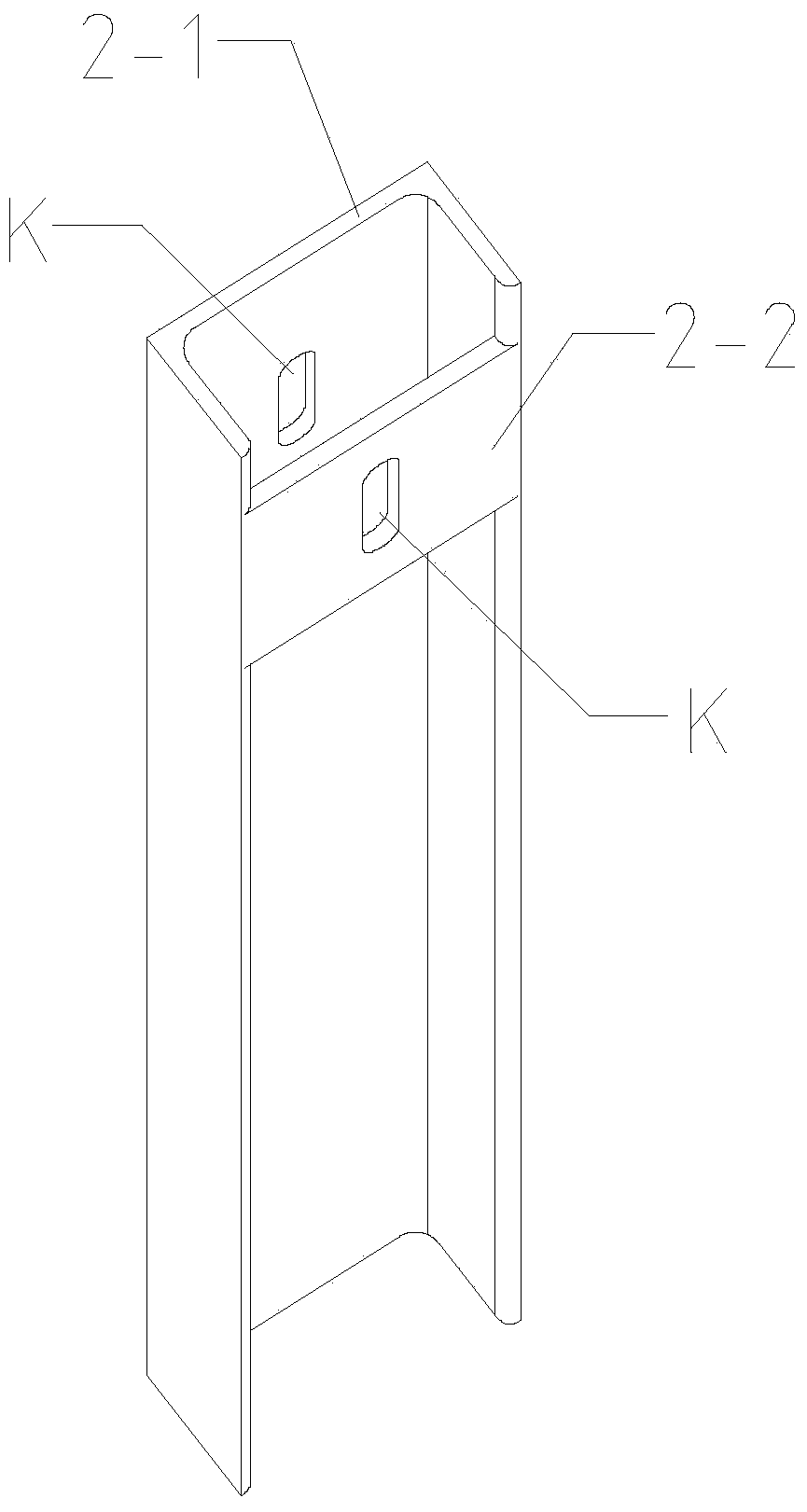

[0018] The present invention is an assembled prefabricated balcony board and balcony support connection structure, which is composed of a balcony board, a C-shaped steel balcony pillar, a steel connector, a connecting plate and an anti-off plate, and a C-shaped opening on the upper part of the C-shaped steel balcony pillar 2 is provided with a connecting plate 2 -2, the connecting plate 2-2 and the corresponding web 2-1 have corresponding limit connecting holes K; the steel connecting piece is composed of an angle steel adapter 3-1 and a clamping steel plate 3-2, and the clamping steel plate 3 -2 has a U-shaped notch, and two clamping steel plates 3-2 are vertically welded on the vertical surface 3-1b of the angle steel adapter 3-1; figure 2 , the right-angled horizontal plane 3-1a of the angle steel adapter 3-1 is connected with the embedded steel connector 1-1 on the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com