Novel labor-saving steel bar binding hook

A new type of steel bar binding technology, which is applied in construction, building structure, and building material processing, can solve the problems of high labor intensity, affecting efficiency, and easy twisting of wires, so as to improve construction efficiency and reduce labor intensity , The effect that the angle is easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

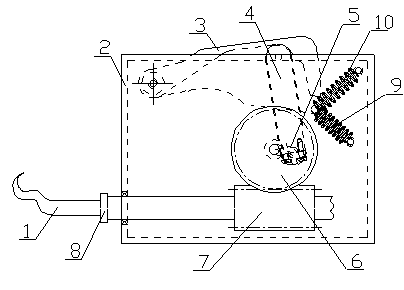

[0014] Below in conjunction with accompanying drawing, the present invention will be further described:

[0015] Such as figure 1 As shown, a new labor-saving steel bar binding hook, including a binding hook 1 and a binding hook driving device, the binding hook driving device is connected with the binding hook 1 and drives the binding hook 1 to rotate, and the binding wire is fastened to the steel bar by rotating the binding hook 1 , bind the steel bars firmly.

[0016] The driving device of the binding hook includes a crank linkage mechanism (4, 5) composed of a housing 2, a pressing block 3, a crank 5 and a connecting rod 4, a worm gear transmission system (6, 7) composed of a worm wheel 6 and a worm 7, Two springs (9, 10). One end of the briquetting block 3 is fixed in the housing 1 through the mandrel, and the other end is a free end, which can freely rotate around the mandrel. The connecting rod 4 of the crankshaft connecting rod mechanism (4, 5) is connected to the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com