Multi-direction stiffness test device and method for fabric

A test device and technology of stiffness, which is applied in the field of fabric multi-directional stiffness test devices, can solve the problems of huge workload, consumption of fabric samples, time-consuming, labor-intensive and material-consuming, etc., and achieve accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

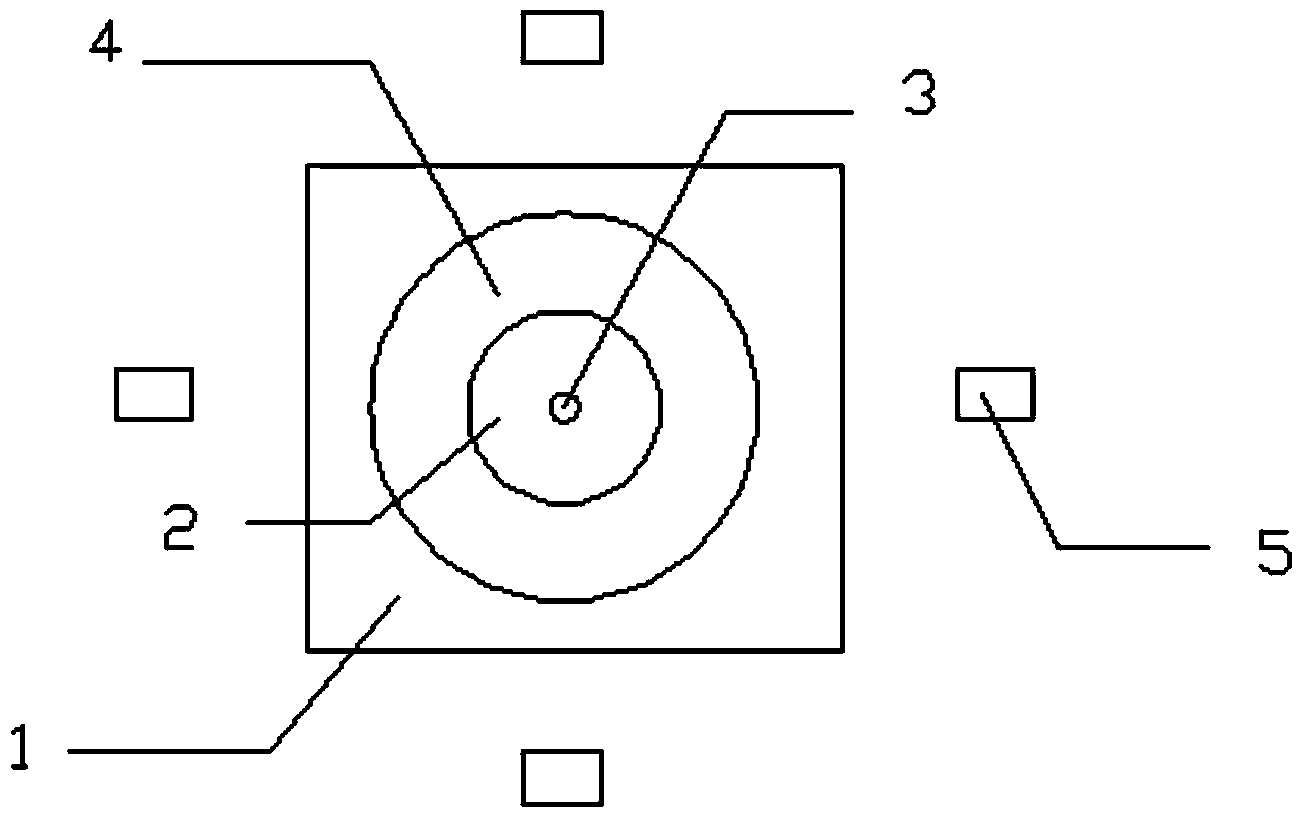

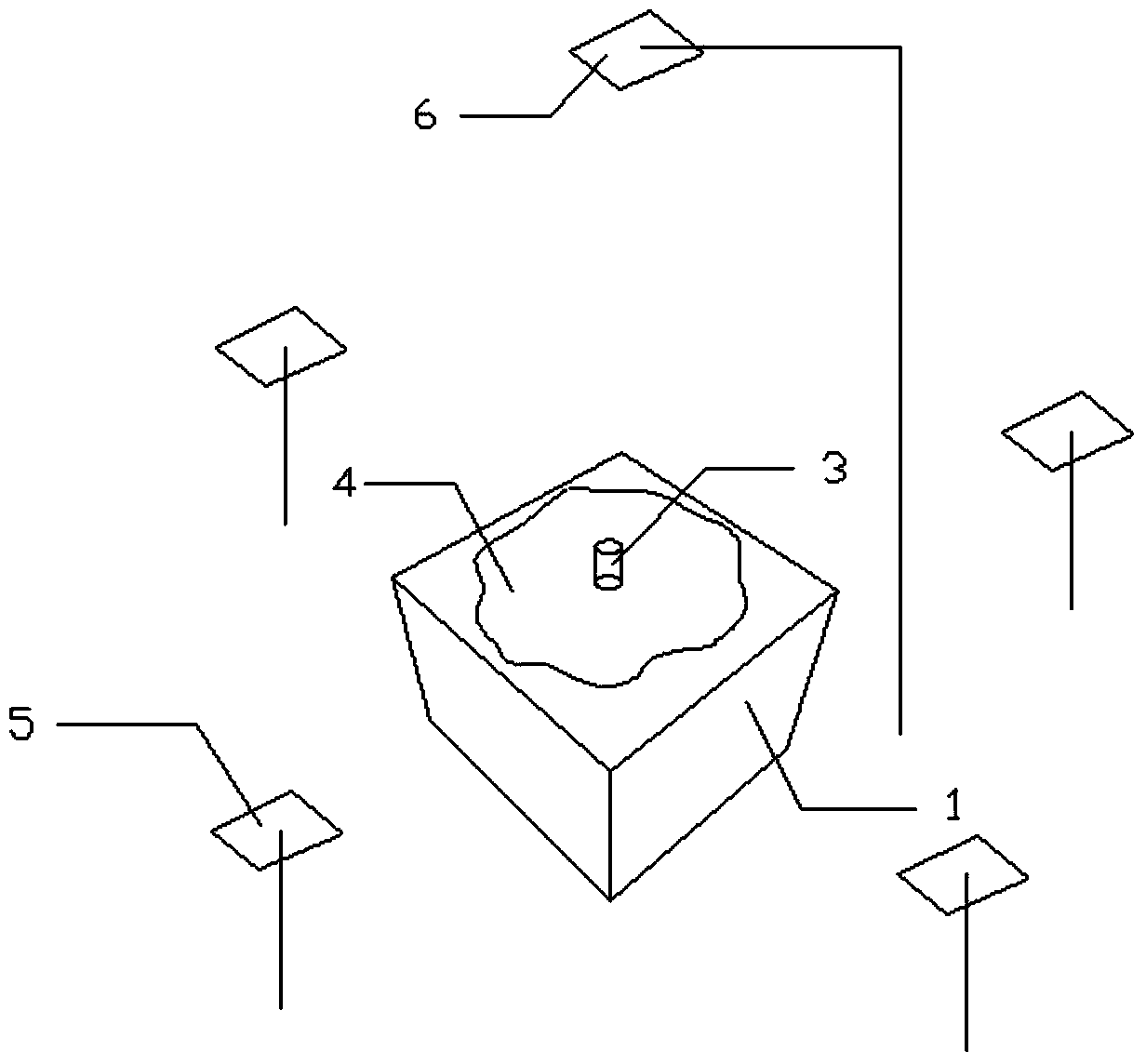

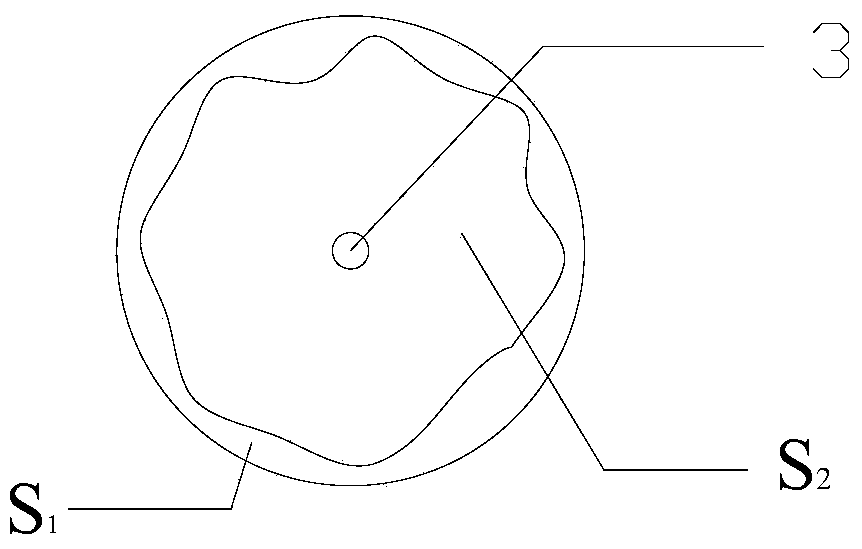

[0015] Embodiment: Fabric multi-directional stiffness testing device, including box-shaped fabric depression platform, pressure applying components, and image pickup device. like figure 1 and figure 2 As shown, the box-shaped fabric depression platform 1 is a hollow cubic box-shaped body, and is provided with a hollow circular upper surface 2, and the upper surface of the depression platform 1 is covered with a layer of plastic wrap or other transparent thin materials (for To prevent the extremely soft fabric from falling directly from the hollow circle once the external force is applied); Fabric weights) are used to apply pressure to the test fabric 4 placed on the sunken platform; the image capture device includes four surrounding planes that are respectively located around the sunken platform, and are located around the sunken platform, and are equidistant from the center of the sunken platform. Digital camera 5, and a digital camera 6 above that is positioned at the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com