Time digital converter (TDC) circuit for power tube sectional drive

A segmented drive, power tube technology, applied in the direction of output power conversion devices, electrical components, etc., can solve the problems of decreased sampling accuracy, unsuitable current detection, etc., and achieve the effect of stable segmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

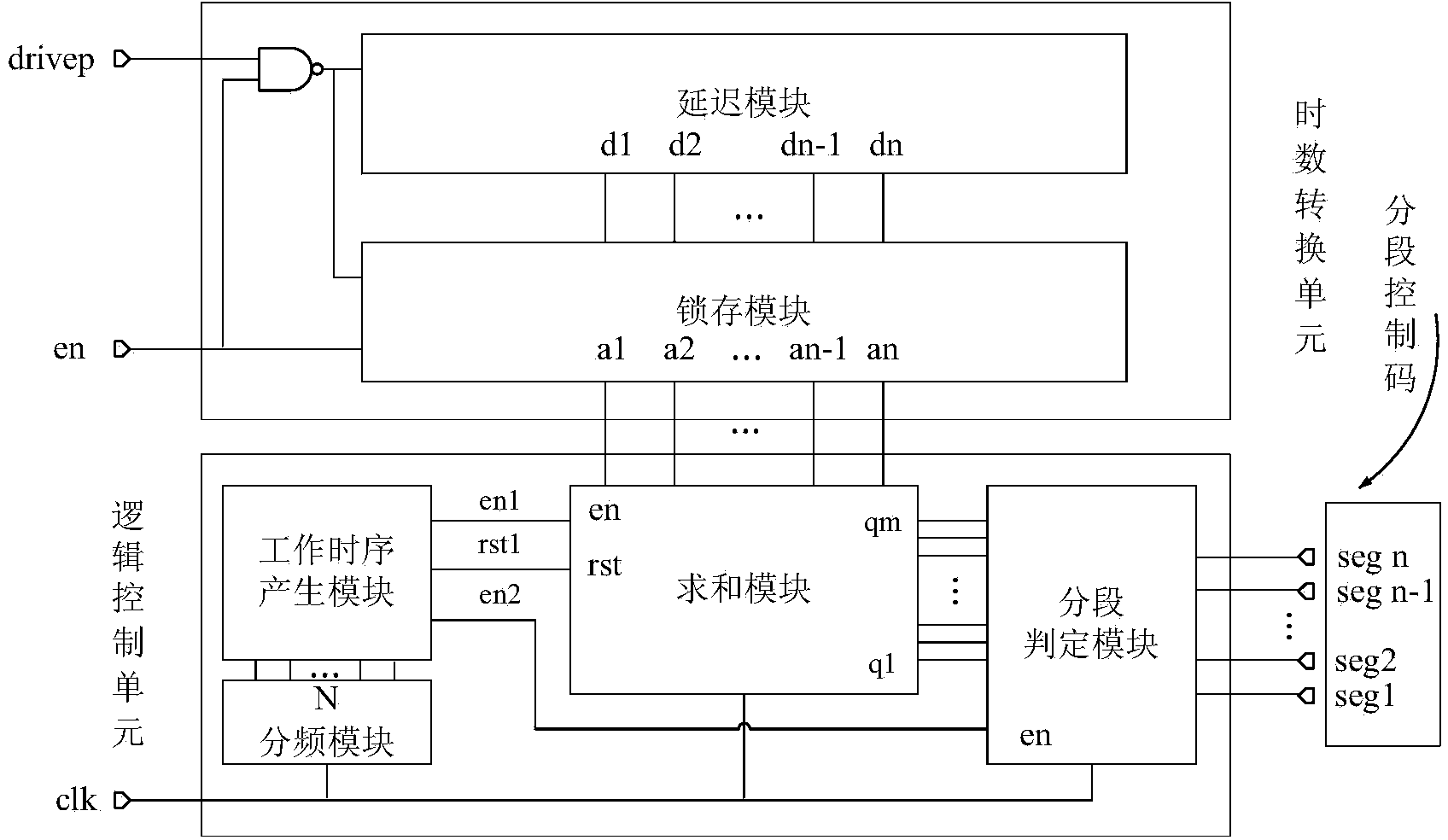

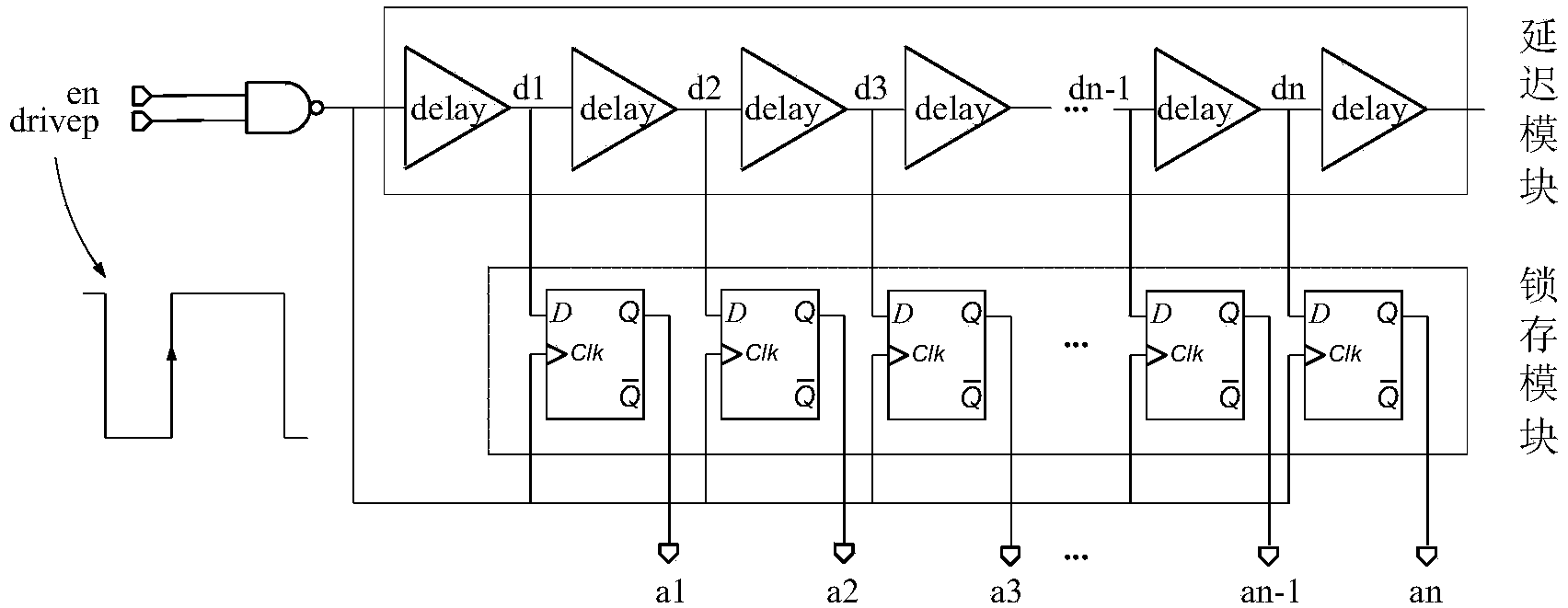

[0035]This example mainly includes a segment-driven power tube, an LC filter circuit, a feedback control unit and the TDC circuit of the present invention. The feedback control unit is connected to the output of the Buck converter to generate a drive signal for the power tube and send it to the TDC module and the buffer circuit of the power tube. The TDC quantifies the conduction time of the power P tube, infers the current load current, and generates a segmented control code. The segment control code is connected to the buffer circuit to drive the power tube in segments.

[0036] In this example, the specific values of some parameters in the aforementioned technical solution are as follows:

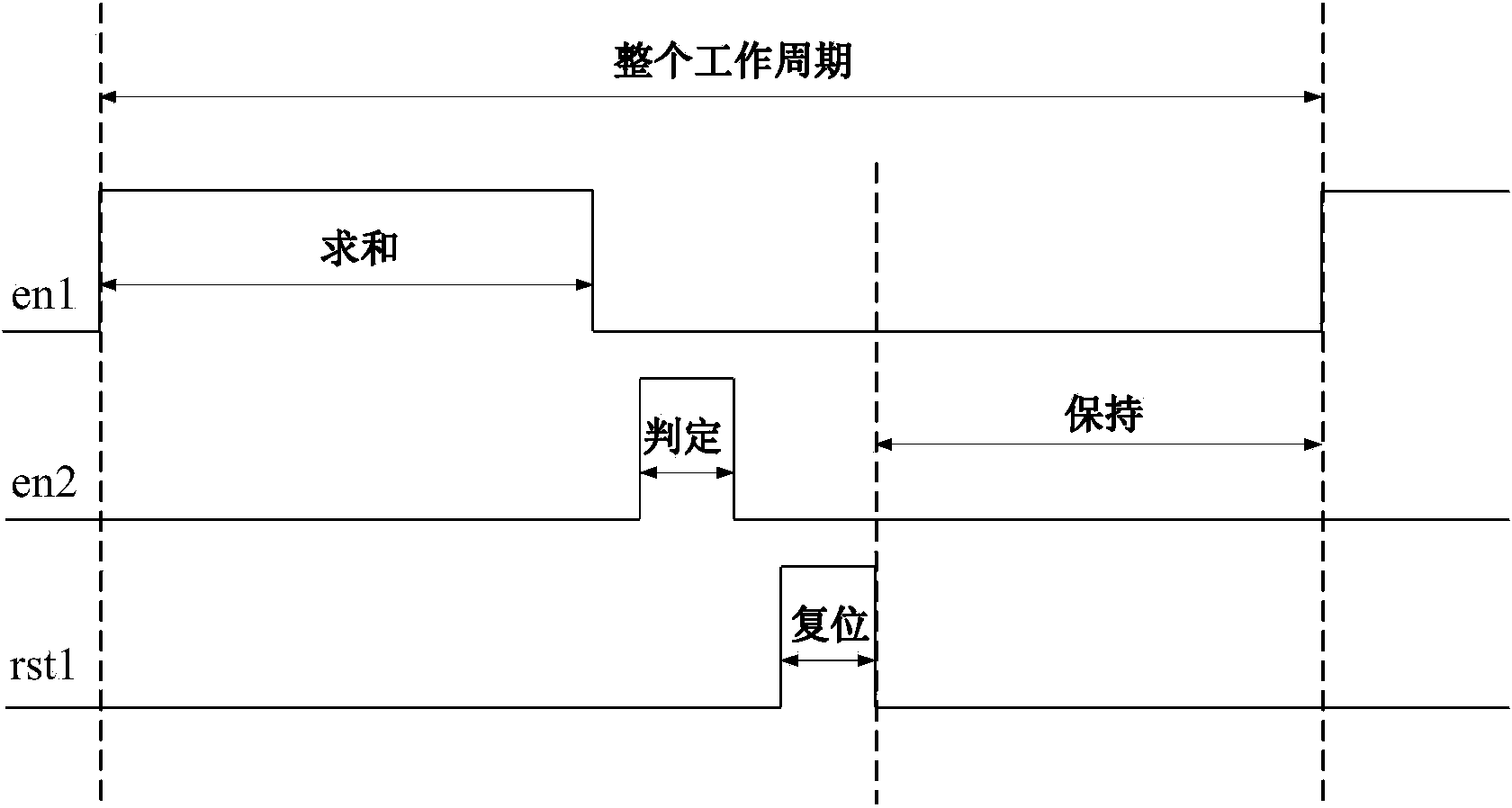

[0037] n=5, m=9, N=32, N 1 =10, N 2 =2,N 3 =2

[0038] That is, there are 5-digit segment control codes (the number of power pipe segments controlled under DCM is 5); the output of the summation module is represented by 9-digit binary numbers (the 10-period summation of 5-digit qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com