Joint module

A technology of modules and snap-fit components, applied in the direction of instruments, electrical digital data processing, electrical components, etc., can solve problems such as deformation and warping, insufficient strength of joints, and inaccurate alignment of the two shells, so as to achieve convenient operation, The effect of increasing joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

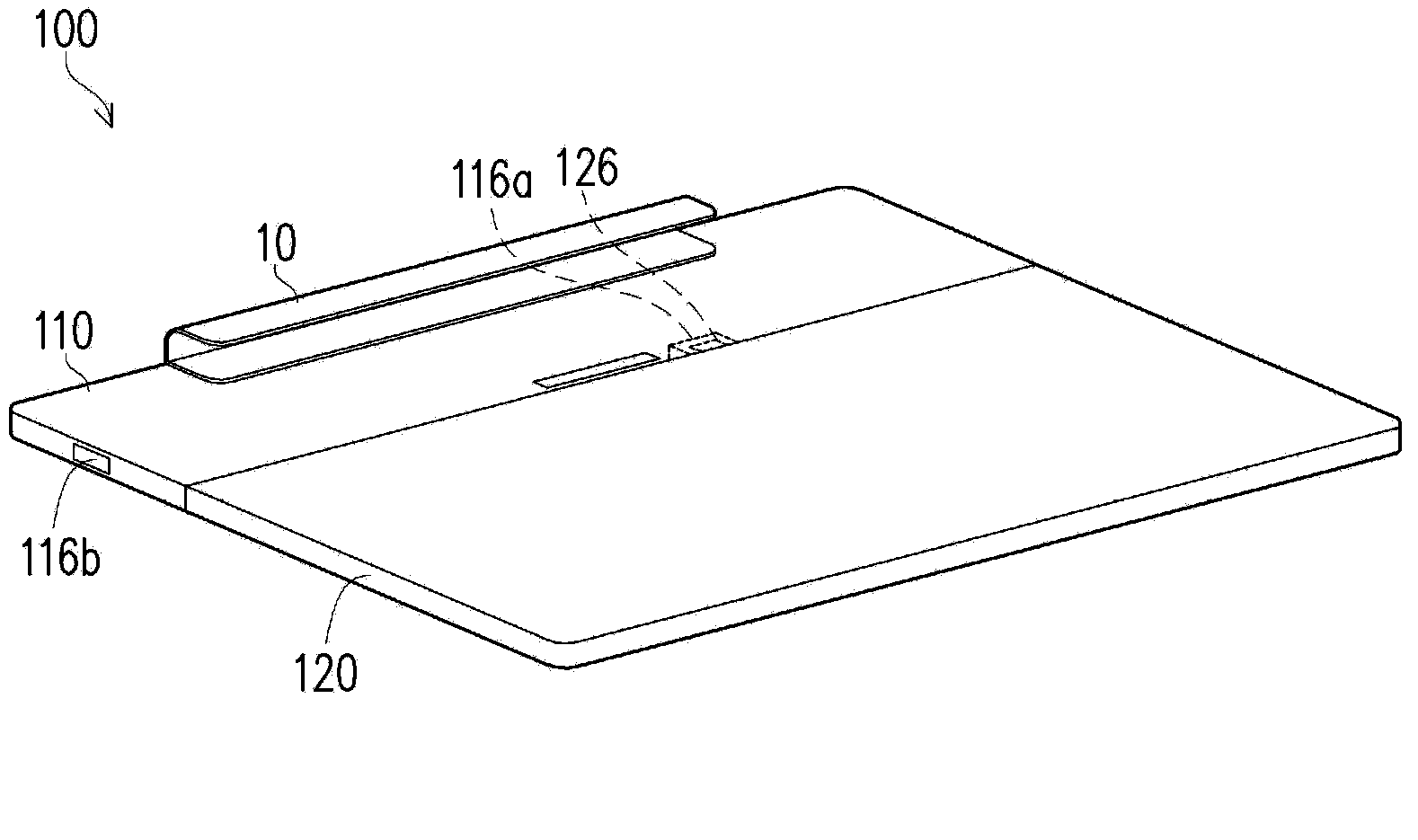

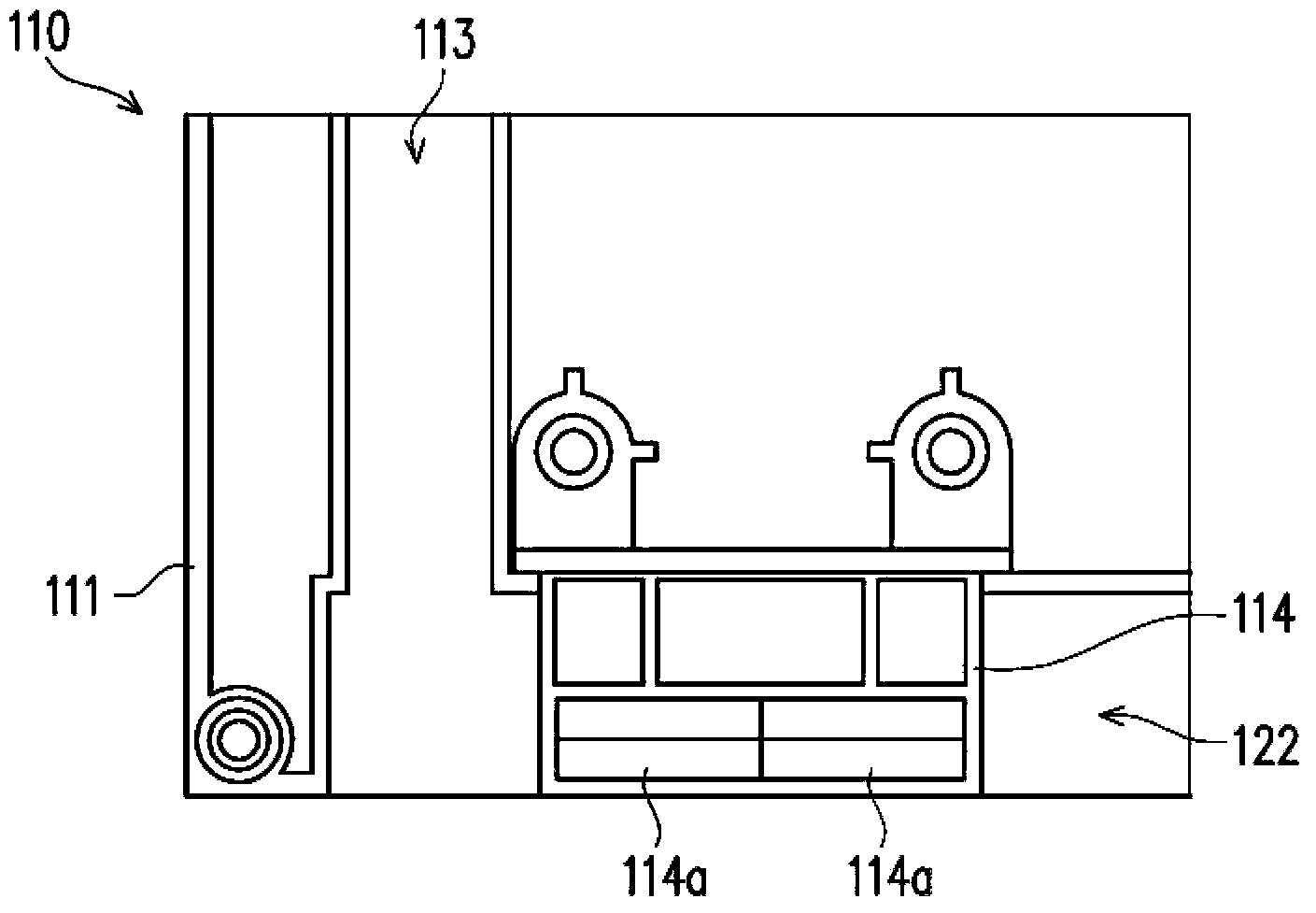

[0058] Figure 1A It is a schematic diagram of an assembled joint module according to an embodiment of the present invention. see Figure 1A , the bonding module 100 of this embodiment includes a first housing 110 and a second housing 120 . In this embodiment, the first housing 110 can be an expansion base, and the first housing 110 includes a first connection port 116 a and an input and output port 116 b. The input and output ports 116b are electrically connected to the first connection port 116a, and can be used for users to insert an external device (not shown). The second housing 120 can be an expansion module, such as a keyboard module, a tablet, or an audio-visual module (such as a speaker, etc.).

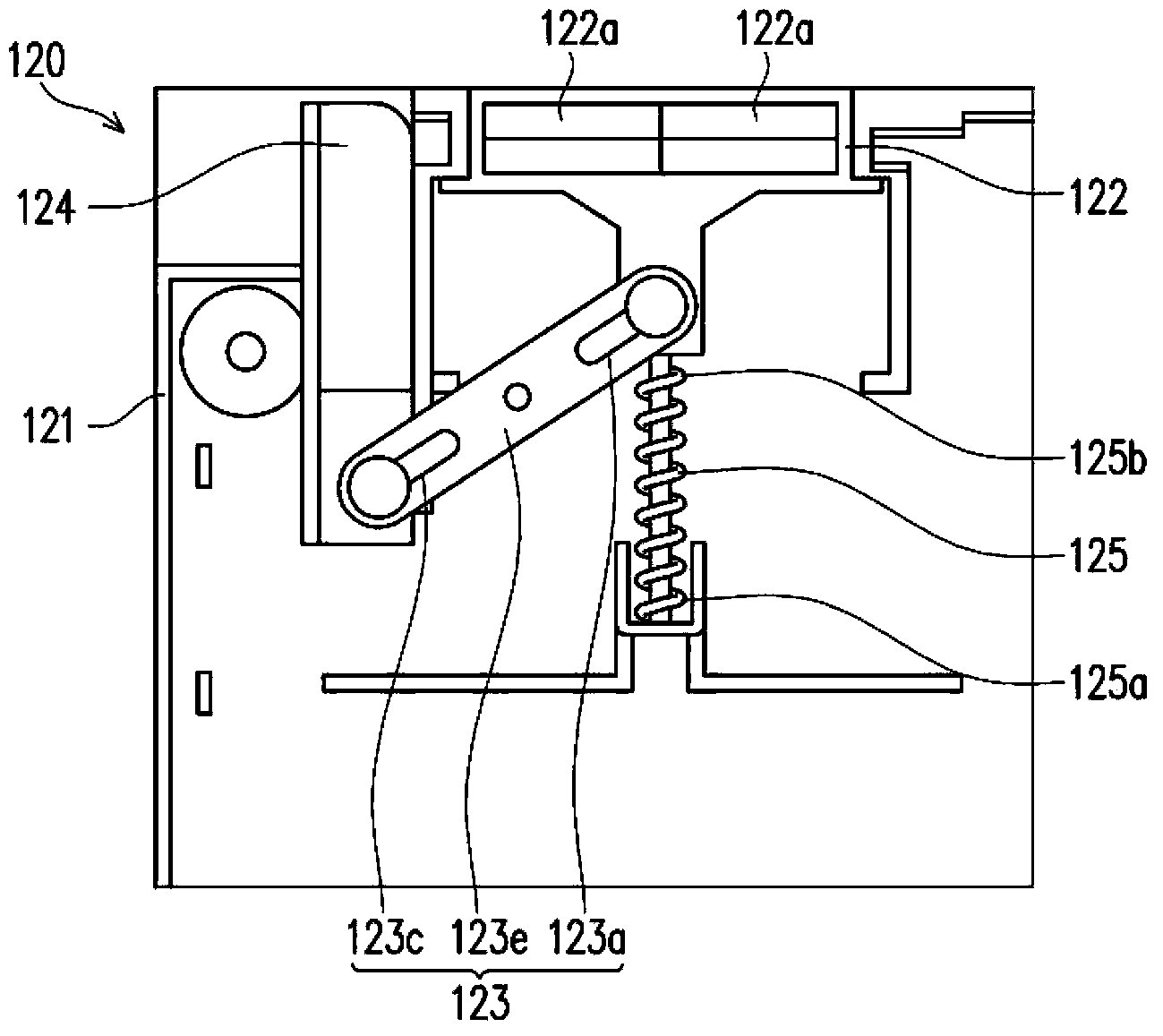

[0059] The second casing 120 includes a second connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com