Pretreatment method for impinging wet steam vapor-liquid two-phase separation

A wet steam and phase separation technology, which is applied in the field of power engineering, can solve the problems of large flow resistance, complex structure, local speed overspeed, etc., and achieve the effect of stable separation efficiency, simple device structure and small flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

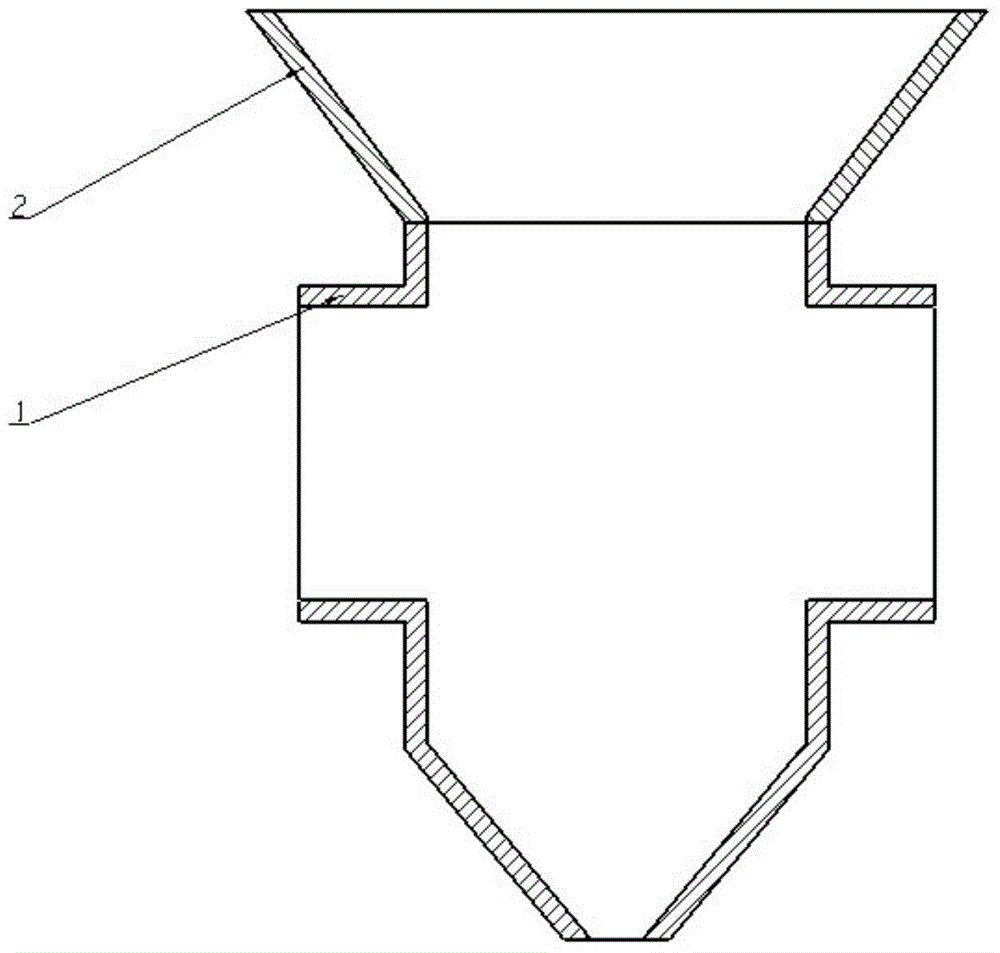

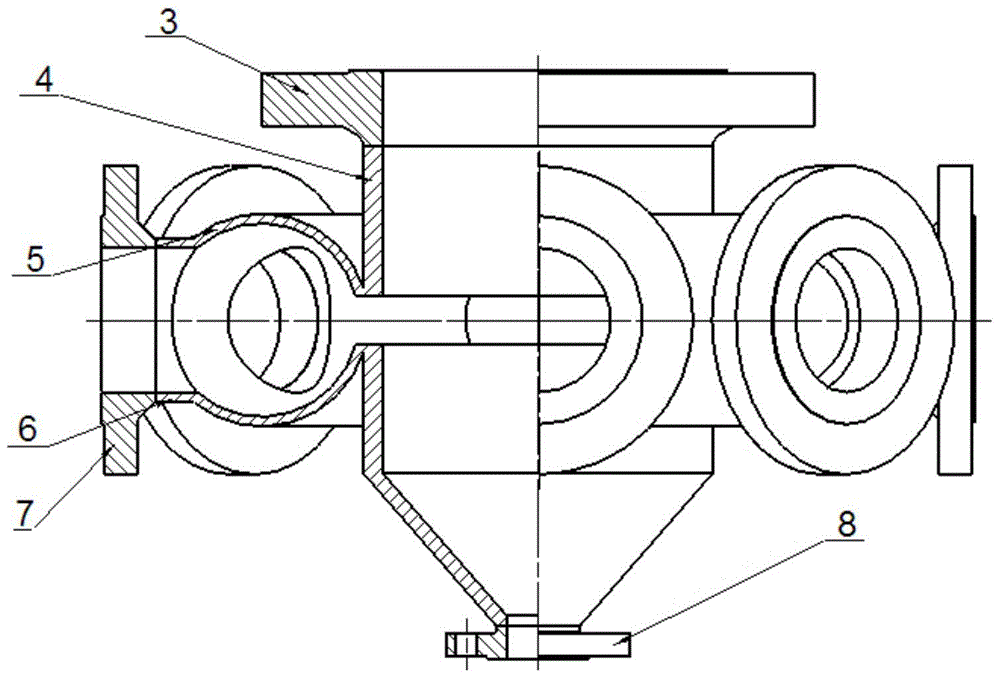

[0015] refer to figure 1 , the device based on the colliding separation method of the present invention includes a wet steam colliding device 1, which is vertically cylindrical, and the size of the lower end is gradually reduced, which is an inverted cone, and the outlet at the lower end is connected with an external hydrophobic collection device; the outlet at the upper end is passed through a diffuser tube 2 Connected to the cyclone separation device, the collision zone in the middle of the cylinder.

[0016] The working principle of the separator is that the wet steam is introduced from around the cylinder of the wet steam collision device 1 through the wet steam guide device, and collides with each other in the middle of the cylinder, the droplet size will increase sharply, and the oversized droplets will Falling under the action of gravity, it is discharged by the drainage device connected to the outlet at the lower end, and the rest of the droplets follow the steam flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com