Method for welding multilayer thin metal sheets and thick metal sheet

A multi-layer metal and welding method technology, applied in welding equipment, metal processing, welding equipment, etc., can solve the problems of unsatisfactory welding products, low brazing strength, low welding efficiency, etc., and achieve the goal of improving welding efficiency and welding quality Effect

Active Publication Date: 2014-04-23

PANGANG GRP ENG TECH

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Among them, brazing is usually used for the welding of multi-layer metal sheets, but brazing often cannot meet the requirements of welded products due to its low strength.

Tungsten argon arc welding is usually used for welding thin metal plates that require high weld strength. Although argon tungsten arc welding

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to view more

Login to view more PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to view more

Abstract

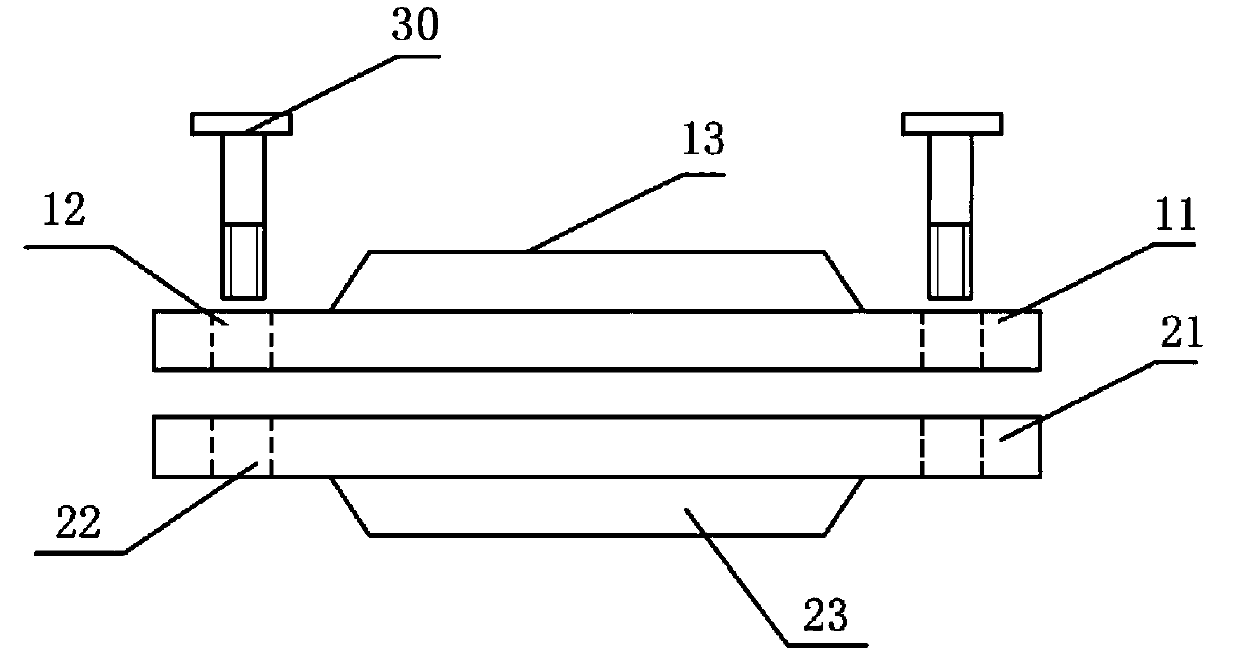

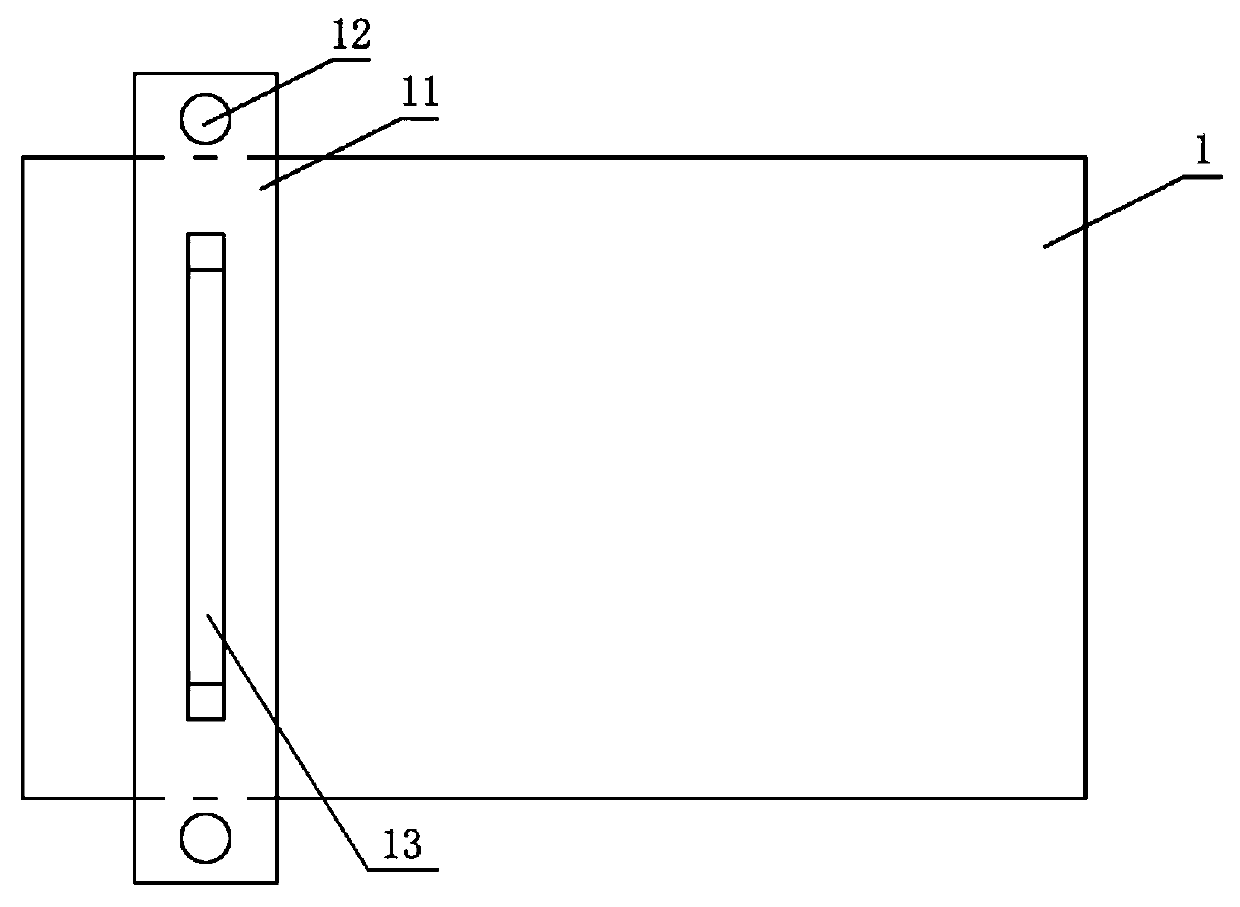

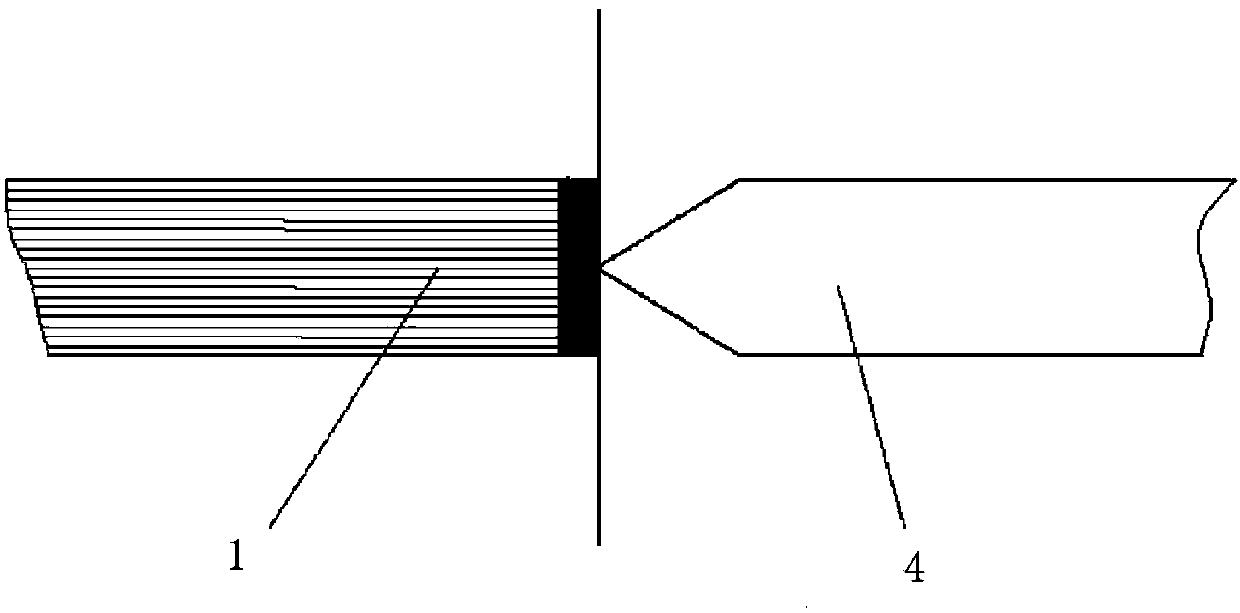

The invention discloses a method for welding multilayer thin metal sheets and a thick metal sheet. The method comprises the following steps that the multilayer thin metal sheets are clamped through a clamp, and the ends of the multilayer thin metal sheets are welded by using metal inertia gas welding; the welded ends of the multilayer thin metal sheets are in butt joint with one end of the thick metal sheet, and then welding is carried out. According to the method for welding the multilayer thin metal sheets and the thick metal sheet, welding efficiency and welding quality between the multilayer thin metal sheets and the thick metal sheet can be remarkably improved.

Description

technical field [0001] The invention belongs to the field of metal welding, in particular, the invention relates to a welding method of multi-layer thin metal plates and thick metal plates. Background technique [0002] At present, the methods for welding thin metal sheets (for example, aluminum and aluminum alloy sheets) mainly include laser welding, brazing, argon tungsten arc welding, and partial solidification welding. Among them, brazing is usually used for the welding of multi-layer metal sheets, but brazing often cannot meet the requirements of welded products due to its low strength. For the welding of metal sheets with high weld strength requirements, argon tungsten arc welding is usually used. Although argon tungsten arc welding can meet the requirements of welding strength, its welding efficiency is relatively low. In addition, although the other welding methods can achieve a small adjustment range of parameters, and can well control the formation and temperature...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): B23K9/173B23K37/04

CPCB23K9/025B23K9/173B23K9/235B23K37/0408B23K2101/16

Inventor 梁恩荣吴荣善陈梦逢潘子祥何耀飞李庭慧付强

Owner PANGANG GRP ENG TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap