Pressure-controllable worm self-locking type anti-loosing fixture

A self-locking, worm technology, used in clamping, clamping devices, manufacturing tools, etc., can solve the problems of uncontrollable clamping force, easy loosening, unreliable clamping, etc., and achieve a simple structure, a reliable anti-loose structure , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

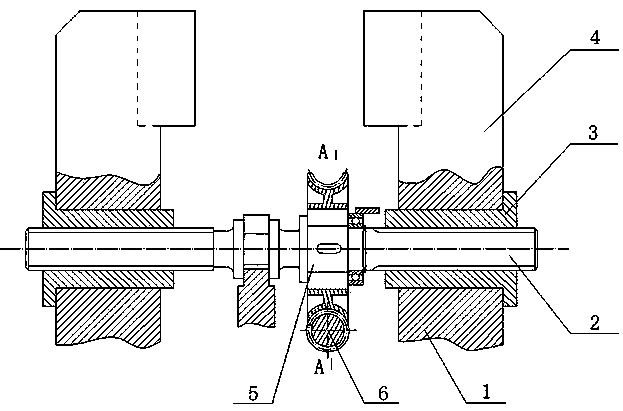

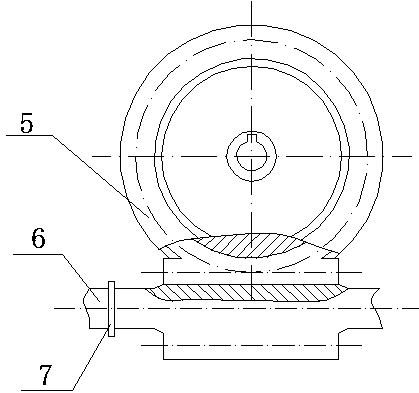

[0019] Such as figure 1 , figure 2 As shown, the pressure controllable worm self-locking anti-loosening fixture includes a fixture seat 1, a screw rod 2, a moving block 3, and a clamping block 4. The upper end of the fixture seat 1 is pressed on the concave edge of the lower end of the moving block 3, and the clamping block 4 The lower end is pressed on the concave edge of the upper end of the moving block 3, and the screw 2 is engaged with the moving block 3, and also includes a worm wheel 5, a worm 6, and a dial 7. The worm wheel 5 is assembled on the screw 2 through a key, and the worm 6 The rolling bearing is assembled on the fixture base 1 and meshed with the worm wheel 5 , and the dial 7 is fixed on the worm 6 .

[0020] The helix angle of the worm 6 is smaller than the equivalent friction angle of the meshing surface with the worm wheel 5 . The worm 6 is a single-head worm, and its cross-sectional tooth profile is an Archimedes spiral.

Embodiment 2

[0022] Such as figure 1 , figure 2 As shown, the pressure controllable worm self-locking anti-loosening fixture includes a fixture seat 1, a screw rod 2, a moving block 3, and a clamping block 4. The upper end of the fixture seat 1 is pressed on the concave edge of the lower end of the moving block 3, and the clamping block 4 The lower end is pressed on the concave edge of the upper end of the moving block 3, and the screw 2 is engaged with the moving block 3, and also includes a worm wheel 5, a worm 6, and a dial 7. The worm wheel 5 is assembled on the screw 2 through a key, and the worm 6 The rolling bearing is assembled on the fixture base 1 and meshed with the worm wheel 5 , and the dial 7 is fixed on the worm 6 .

[0023] The helix angle of the worm 6 is smaller than the equivalent friction angle of the meshing surface with the worm wheel 5 . The worm 6 is a double-headed worm, and its cross-sectional tooth profile is a concave arc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com