Auxiliary tooling for railway vehicle trunking installation

A technology for auxiliary tooling and railway vehicles, applied in the direction of manufacturing tools, hand-held tools, etc., can solve the problems of affecting the quality of wiring, inconvenient operation, uneven cables, etc., to ensure the quality of wiring, avoid head-up operations, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] First, a brief description will be given of the "wire duct" of the present invention. The trunking can be a long shell used for placing wires and signals in railway vehicles, generally including a trunking body and a trunking cover, and one side of the trunking body forms an opening, that is, from the perspective of the cross section, the trunking body It is generally in the shape of a "U", and the trunking cover is buckled on the opening of the trunking body, so that the cross section of the entire trunking is "mouth"-shaped to fully protect the cables inside. Wherein, the trunking body is generally a metal stamping part, the trunking cover is made of insulating material, and the connection relationship between the trunking body and the trunking cover can be a common method in the field, which is not particularly limited in the present invention.

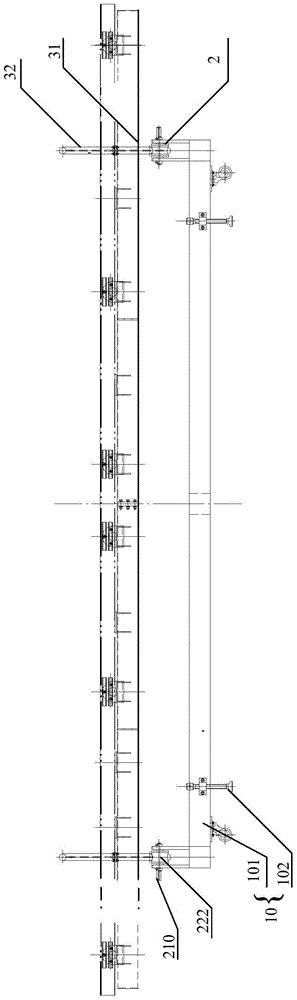

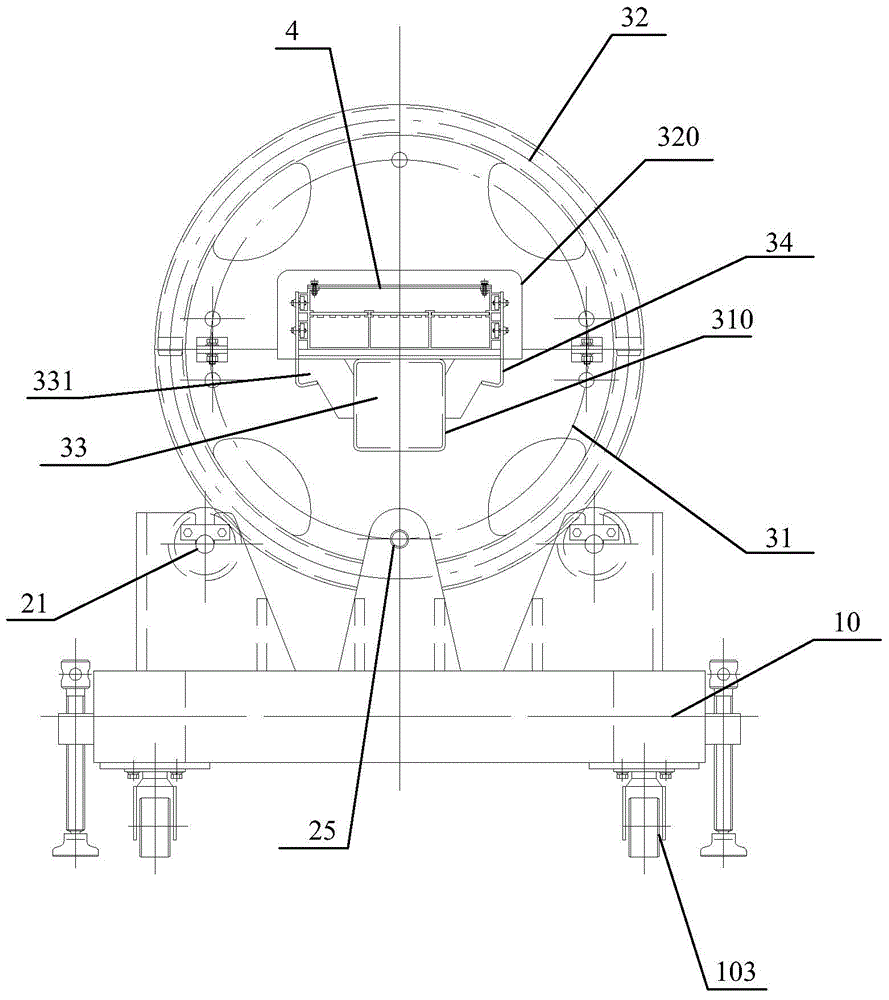

[0013] figure 1 It is a front view of an embodiment of the auxiliary tooling for installation of railway vehicle trunking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com