Instrument table for engineering machine

A technology for construction machinery and instrument panels, applied in instrument panels, transportation and packaging, vehicle components, etc., can solve the problems of high labor-hour consumption, many procedures, and high installation costs, and achieve the goal of improving work efficiency, simple and fast operation, and reducing man-hours. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

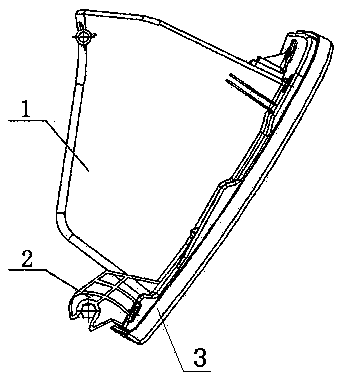

[0008] Depend on figure 1 It is known that an instrument panel for construction machinery includes a cover plate 1 and an instrument panel body bottom shell 3, the cover plate is provided with a mounting angle 2, and the cover plate 1 is inserted into the instrument panel body bottom shell through the installation angle clamp 2 3, the instrument panel body bottom shell 3 is provided with a transverse convex arc and a longitudinal convex arc.

[0009] During installation, it is only necessary to install the installation clip angle into the corresponding installation position of the bottom shell 3 of the instrument panel body, and the original pin shaft part is omitted, so the installation and disassembly are simple and convenient. The upper surface of the cover plate 1 forms an upwardly convex shape with a beautiful appearance, which is convenient for the driver to observe the changes of the instrument more easily, and is equipped with a sealing ring, which has strong sealing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com