a labeling mechanism

A labeling and labeling technology, applied in the directions of labeling machines, labels, packaging, etc., can solve the problems of increasing labor intensity of workers, reducing product quality, and low labeling efficiency, so as to reduce labor intensity, improve product quality, and label quickly and accurately. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

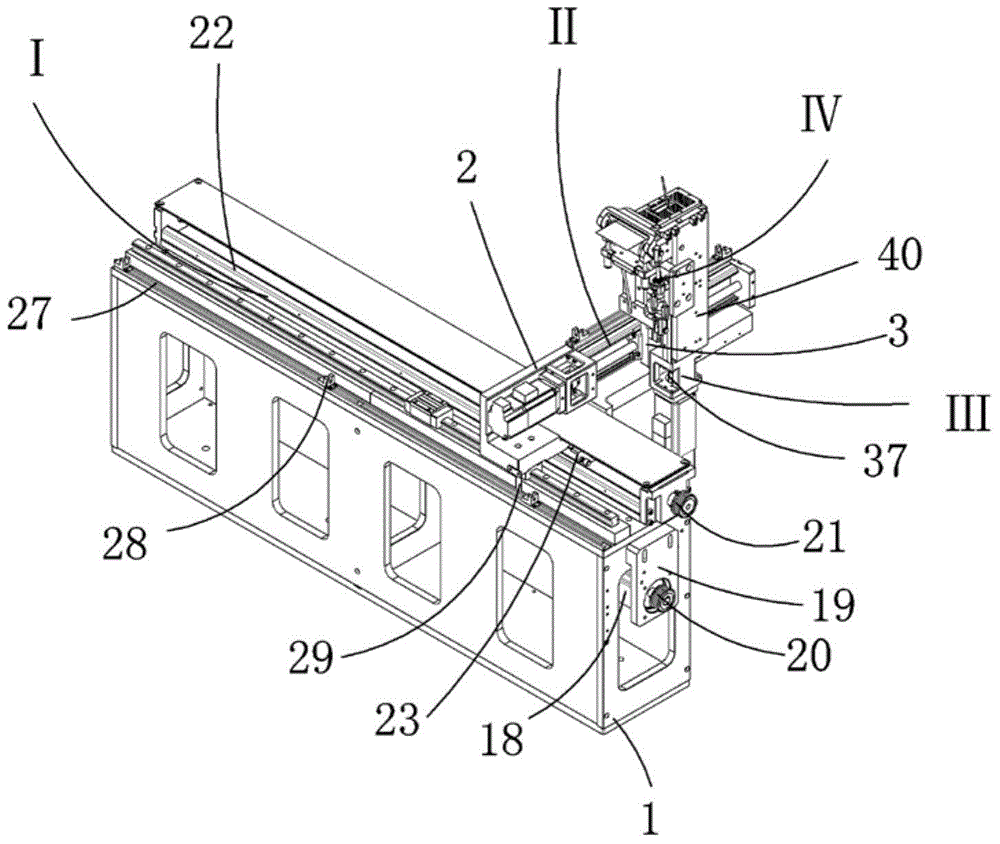

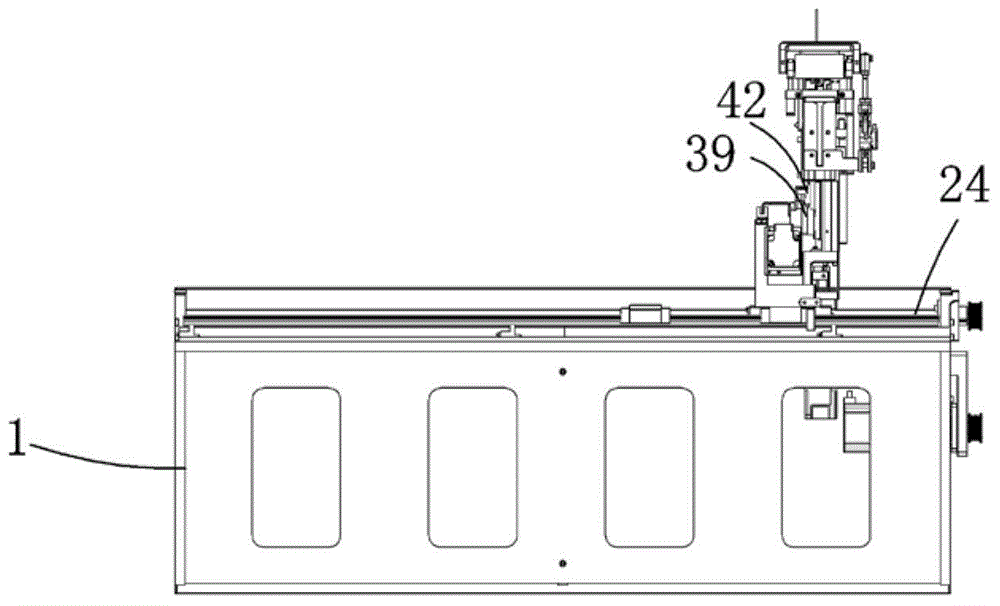

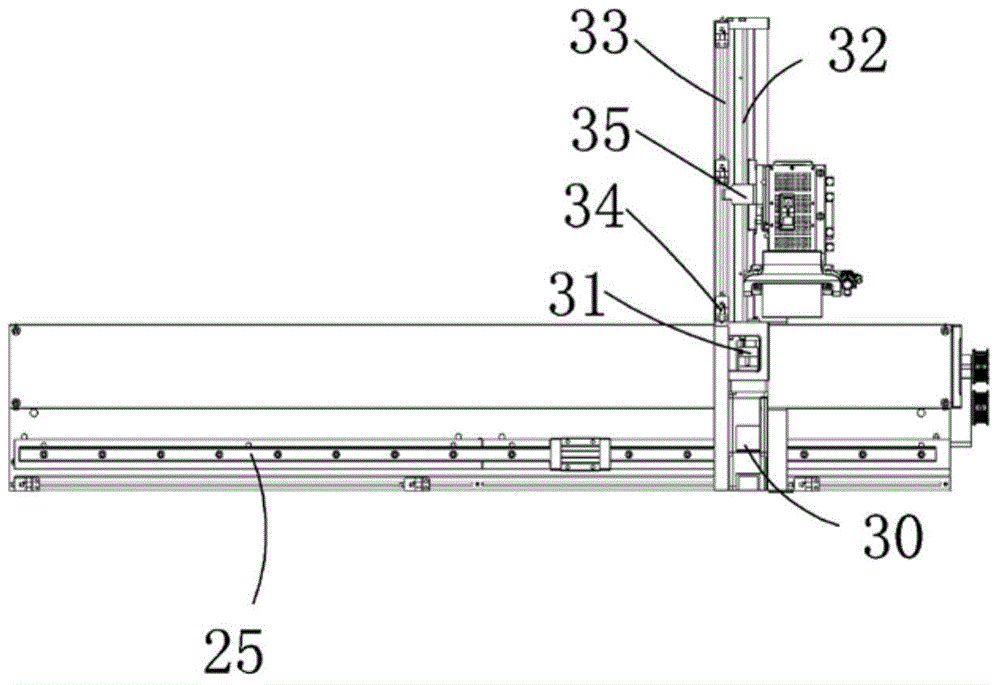

[0024] Examples, see attached Figure 1-9 , a labeling mechanism, which includes a base 1, an X-axis mechanism I, an XY connection angle 2, a Y-axis mechanism II, a YZ module connecting plate 3, a Z-axis mechanism III and a labeling mechanism IV, and the X-axis mechanism is installed on the base Above; the Y-axis mechanism is installed on the X-axis mechanism through the XY connection angle; the Z-axis mechanism is installed on the Y-axis mechanism through the YZ module connecting plate.

[0025] The labeling mechanism includes a reinforcing plate 4, a suction plate 5, a laser 6, a cylinder mounting plate 7, a lifting cylinder 8, a lifting plate 9, a roller connecting plate 10, a roller 11, a pen-shaped cylinder mounting plate 12, a pen-shaped cylinder 13, and a label pressing block 14. Horizontal adjustment cylinder 15, scanner adjustment plate 16 and two-dimensional code scanner 17, the top of the Z-axis mechanism is fixedly installed with a reinforcement plate, and the suct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com