Composite calcium sulfonate lubricating grease composition and preparation method thereof

A technology of lubricating grease composition and compound calcium sulfonate, applied in the directions of lubricating composition, petroleum industry, thickening agent, etc., can solve the problems of increased cost, low conversion efficiency, etc., to prevent overflow, improve utilization rate, increase The effect of dwell time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

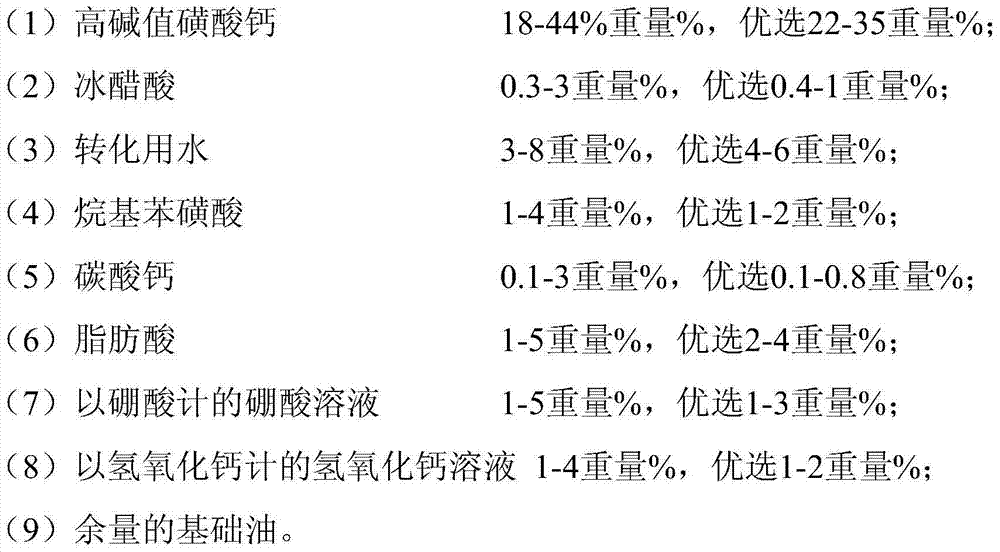

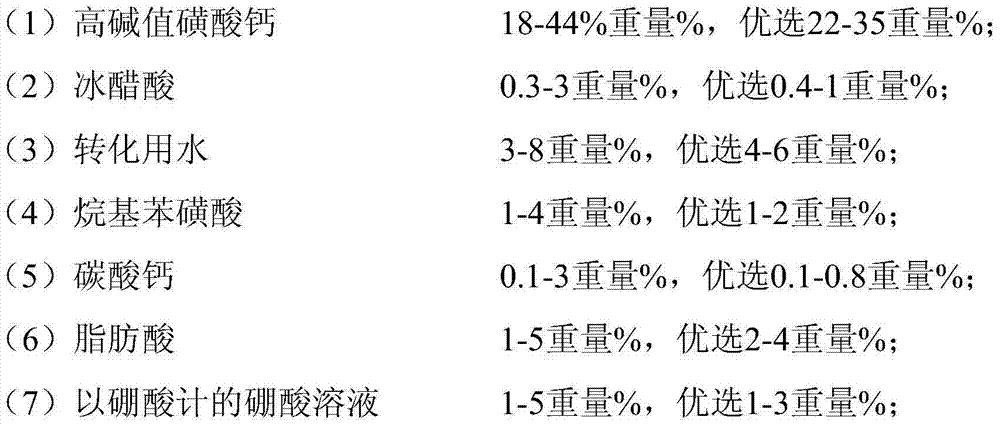

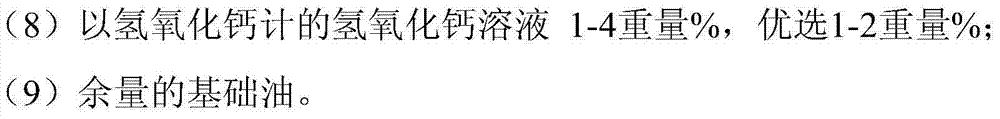

[0045] The preparation method of the composite calcium sulfonate grease composition mentioned in the present invention: it is characterized in that comprising the following steps:

[0046](1) Add base oil accounting for 40-80% of the total base oil and fatty acid accounting for 40-80% of the total fatty acid into the reactor, heat it to about 80°C-85°C and stir evenly, then add high Alkaline value calcium sulfonate, calcium carbonate, conversion water accounting for 50-75% of the total conversion water, and alkylbenzenesulfonic acid accounting for 50-75% of the total amount of alkylbenzenesulfonic acid are added to the above mixture in turn, keeping 80 Stir continuously for 5-10min at around -85°C;

[0047] Wherein, the addition of base oil is preferably 50-65% of the total amount of base oil, the addition of fatty acid is preferably 50-60% of the total amount of fatty acid, and the addition of water for conversion is preferably 65-69% of the total amount of conversion water, ...

Embodiment 1

[0066] In a reaction vessel with a capacity of 1L, put 230g of 150BS base oil (Rwe Group, the same below), 11g of lauryl hydroxystearic acid, heat and stir to 80°C; after the lauryl hydroxystearic acid is fully dissolved, add in sequence 200g of high alkali value calcium sulfonate T106D with a total base value of 400mgKOH / g (Jinzhou Kangtai Lubricating Oil Additive Co., Ltd., the same below), 2g of light calcium carbonate (Zhejiang Xuefeng Calcium Carbonate Co., Ltd., the same below), 20g of conversion water , 7.5g of dodecylbenzenesulfonic acid, stirred at 80°C for 5min; added 3.6g of glacial acetic acid, heated to 96°C, stirred for 60min, the system gradually became viscous; then added 10g of transformation water, 3.8g of dodecylbenzene Benzenesulfonic acid and 1.8g glacial acetic acid (Nantong Huiyu Chemical Co., Ltd., the same below), continue to stir and react at 96°C for 90min, the system gradually becomes viscous, and finally becomes semi-fluid fat; add 200g150BS base oi...

Embodiment 2

[0077]In a reaction vessel with a capacity of 1L, put 190g of 500SN base oil (Rwe Group) and 7.5g of dodecyl hydroxystearic acid, heat and stir to 80°C; after the dodecyl hydroxystearic acid is fully dissolved, add 200g of total High alkalinity calcium sulfonate T106D with an alkalinity of 400mgKOH / g, 4g light calcium carbonate, 16g transformation water, 4.8g dodecylbenzenesulfonic acid, stir at 80°C for 5min; add 3.6g glacial acetic acid, heat up to 100 ℃, stirred and reacted for 50 minutes, the system gradually became viscous; then sequentially added 8g of transformation water, 2.4g of dodecylbenzenesulfonic acid and 1.8g of glacial acetic acid, and continued to stir and react at 100℃ for 80min, and the system became viscous and fatty. Finally, it becomes semi-fluid and fatty; add 120g 500SN base oil, 6g calcium hydroxide (dissolved in 3 times water), 8g boric acid (dissolved in 3 times hot water at 95°C), heat up to 105°C and react for 30min; heat up to 110°C ℃, add 5g of d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com