Hairbrush roller for spinning

A brush roller and brush technology, applied in the direction of floating yarn, layered products, chemical instruments and methods, etc., can solve the problems of single function, increased cost, economic loss, etc., to speed up the work process, reduce costs, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be further described in detail below.

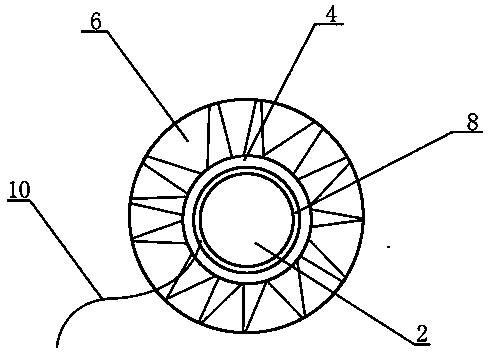

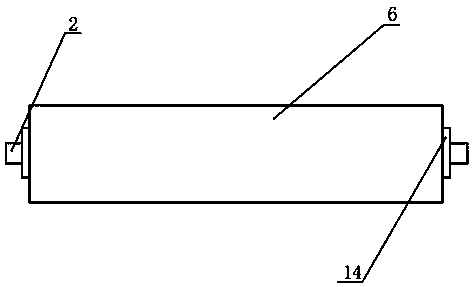

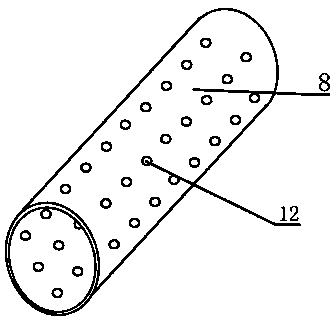

[0016] Such as figure 1 , figure 2 and image 3 Shown, a kind of weaving brush roller of the present invention, it comprises rotating shaft 2, drying layer 4 and hair brush layer 6, is provided with drying layer 4 between rotating shaft 2 and hair brush layer 6, rotating shaft 2 and drying There is also a heating layer 8 between the layers 4, and the heating layer 8 is connected to the power supply through the wire 10; the heating layer 8 is made of stainless steel; the heating layer 8 is evenly distributed with several rows of circular through holes 12; the thickness of the heating layer 8 is 0.2 cm; the rotating shaft 2, the drying layer 4, the brush layer 6 and the heating layer 8 are detachably connected; the two sides of the rotating shaft 2 are respectively screwed with a fixer 14.

[0017] When the drying layer 4 is in contact with fabrics and cloths, it can absorb the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com