Top-mounted ball valve

A ball valve, mounted technology, used in valve devices, cocks including cut-off devices, engine components, etc., can solve problems such as short life and poor sealing reliability, and achieve the effect of eliminating wear, prolonging service life, and bidirectional reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

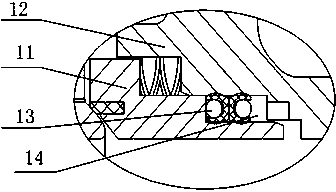

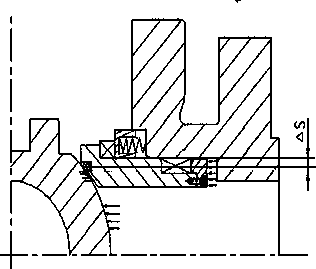

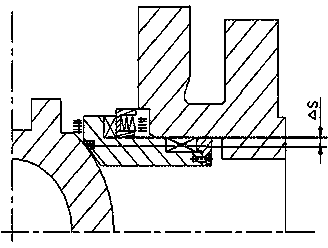

[0031] Such as Figure 4Shown is a top entry ball valve of the present invention, including a retainer 3 located between the ball 1 and the valve body 2, the retainer 3 and the ball 1 are sealed and connected by a sealing material 4, and a seal is provided between the retainer 3 and the valve body 2 5, a limiter 6 is provided between the valve body 2 and the retainer 3, a sealing gap for placing the seal 5 is formed between the limiter 6 and the retainer 3, and one end of the seal 5 abuts against the end of the retainer 3 On the radial end face, the other end abuts against the limiting member 6 , the outer peripheral surface of the limiting member 6 is threadedly connected with the valve body 2 , and the limiting member 6 is connected with the fixer 3 in anti-rotational connection.

[0032] The above-mentioned technical solution is the core technical solution of the present invention. The retainer 3 and the ball 1 are hermetically connected through the sealing material 4 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com