Multilayer micro-channel condenser

A condenser and micro-channel technology, which is applied to evaporators/condensers, refrigerators, refrigeration components, etc., can solve the problems of increasing the volume of refrigerators and freezers, and achieve the effects of increasing heat dissipation time, improving heat dissipation efficiency, and improving heat dissipation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

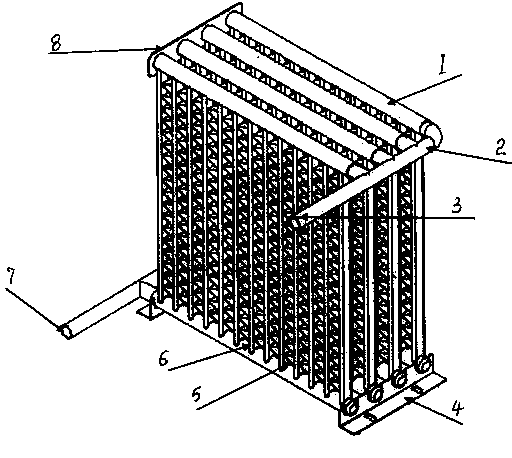

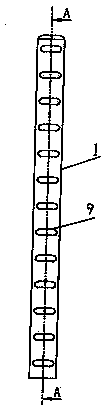

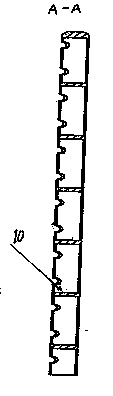

[0009] This technical solution solves the problems of heavy weight and poor heat dissipation area efficiency of existing condensers, see figure 2 and Figure 4 As shown, one end of the unit header 1 is sealed, and the unit header 1 is provided with a grooved mouth 9, and every two grooved holes are separated by a stopper 10, and the nozzles at both ends of the microchannel tube 6 are Unit headers are respectively installed and correspondingly welded with the groove openings on them, and aluminum fins 5 are welded in the middle of every two microchannel tubes 6 to form a heat dissipation unit. The shape of the aluminum fins is wavy, and the overall The collecting pipe 2 is processed with butt joints connected with a plurality of cooling units to form a condenser after being welded. The bottom of the condenser is welded with brackets 4 respectively, and there are assembly holes for installation on the brackets. The sealed end of the upper unit header of the condenser is welded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com