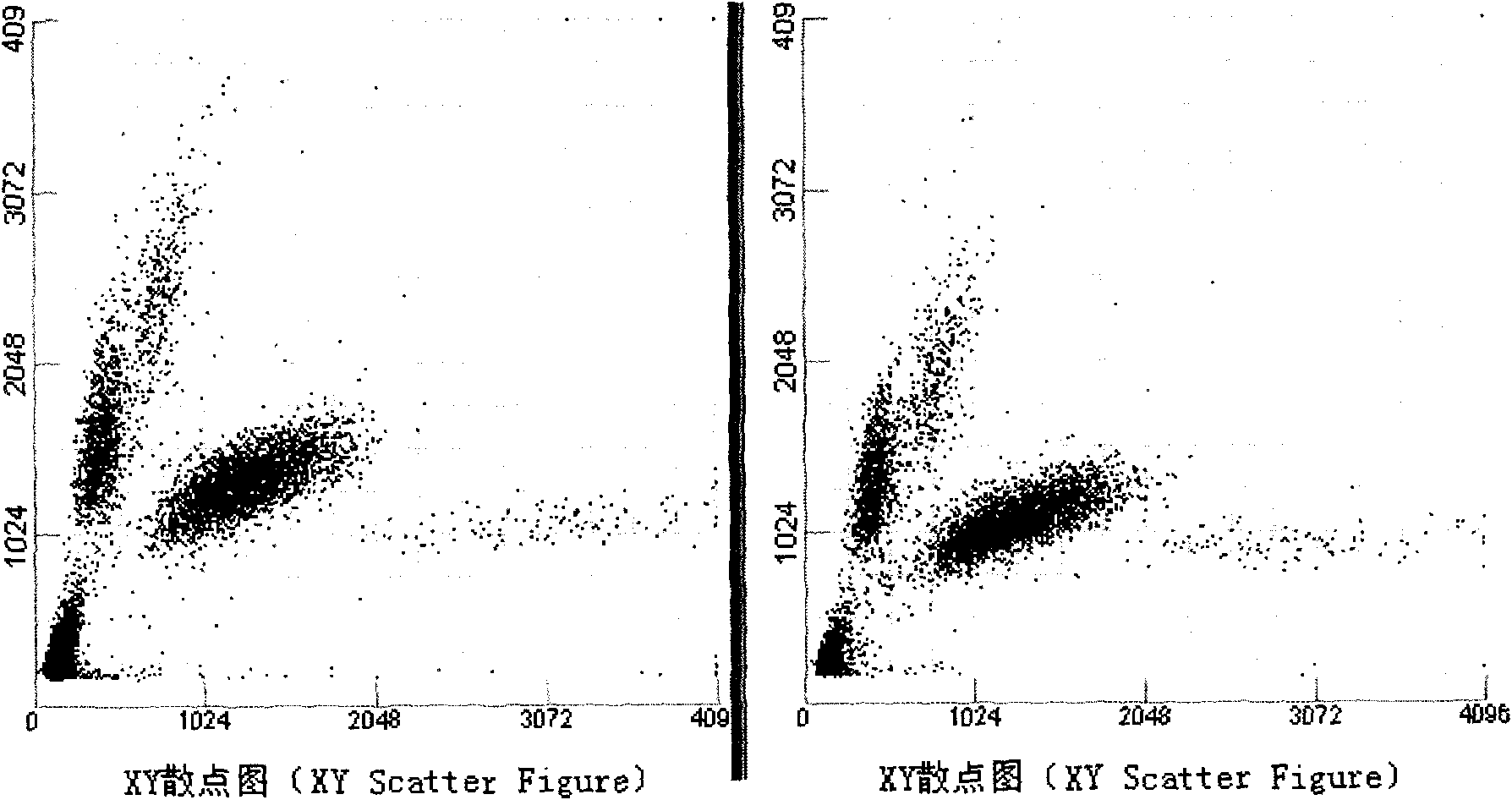

Particle analyzer, constant-temperature reaction system and constant-temperature reaction method

A reaction system and constant temperature technology, applied in the field of particle analyzers, can solve the problem that the accuracy of test results needs to be improved, and achieve the effect of prolonging heating or cooling time, reducing influence, and improving accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

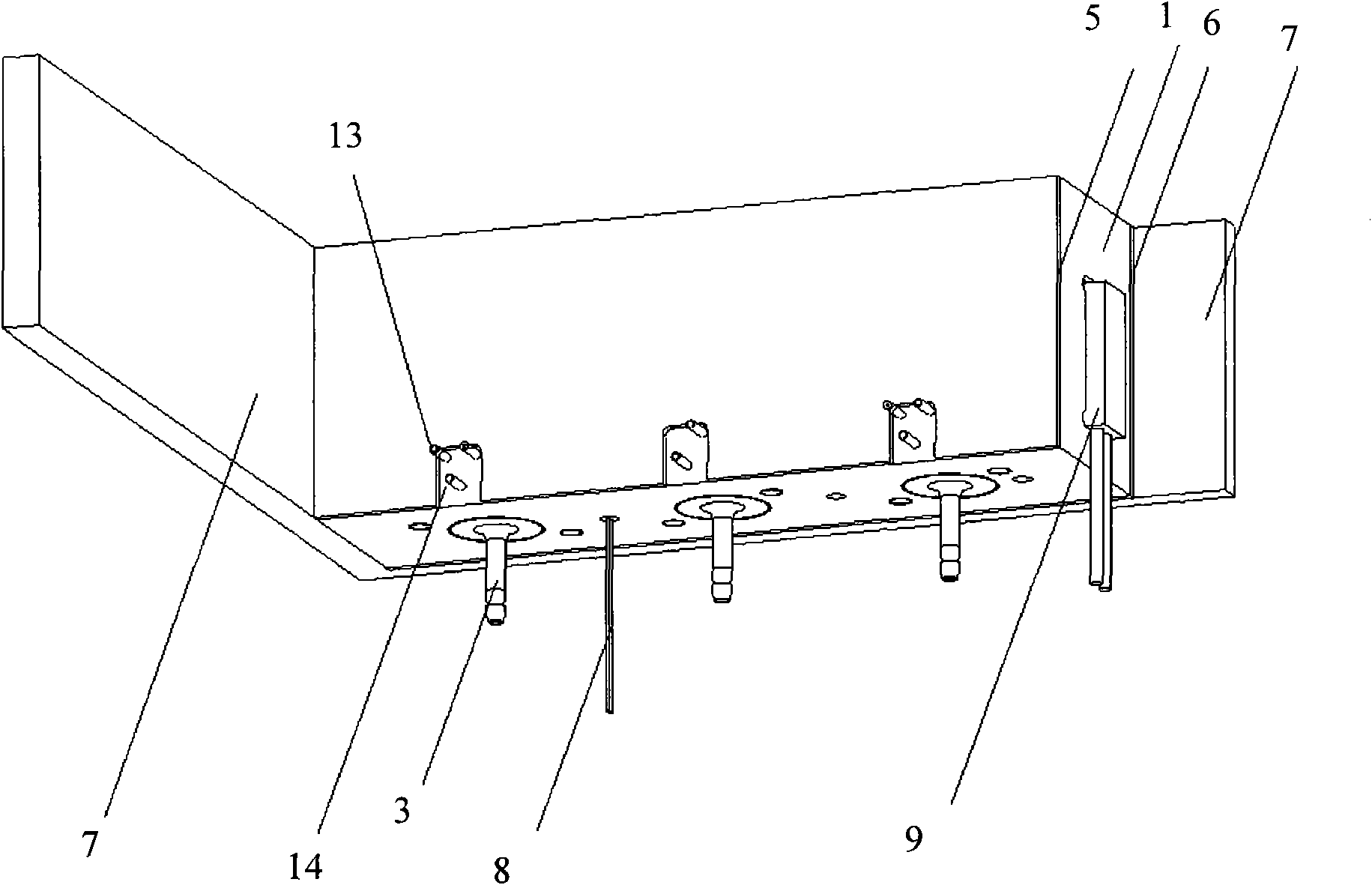

[0016] Hereinafter, the present invention will be further described in detail through specific embodiments in conjunction with the drawings.

[0017] In an embodiment, the constant temperature reaction system includes a reaction tank, a dye tube, and a constant temperature control device. The reaction tank provides a constant temperature reaction place for reactants (such as reagents and blood cells), and generally includes a main board and an incubation tank. The incubation tank is located inside the main board. For example, an independent incubation tank is installed in the cavity of the main board or the main board cavity is directly used as an incubation tank. There may be one or more incubation tanks, and the incubation tank may be columnar, spherical or ellipsoidal. The main board is mainly used to provide a constant temperature environment for the reaction of the reactants, and the incubation tank provides a reaction place for the reactants; the dye tube is used to transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com