Sheet metal drawing device for electronic universal testing machine

A universal testing machine and electronic technology, which is applied in the direction of measuring device, applying stable tension/pressure to test the strength of materials, analyzing materials, etc., can solve the problems such as difficult removal of deep-drawing parts and difficult control of blank-holding force, and save molds The effect of material cost, reduced test cycle, and quick disassembly and assembly of molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

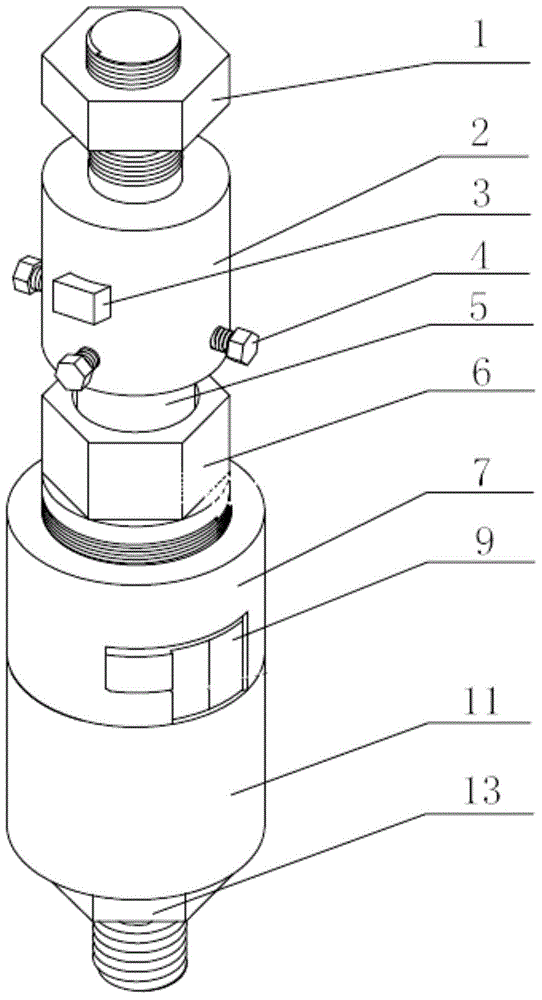

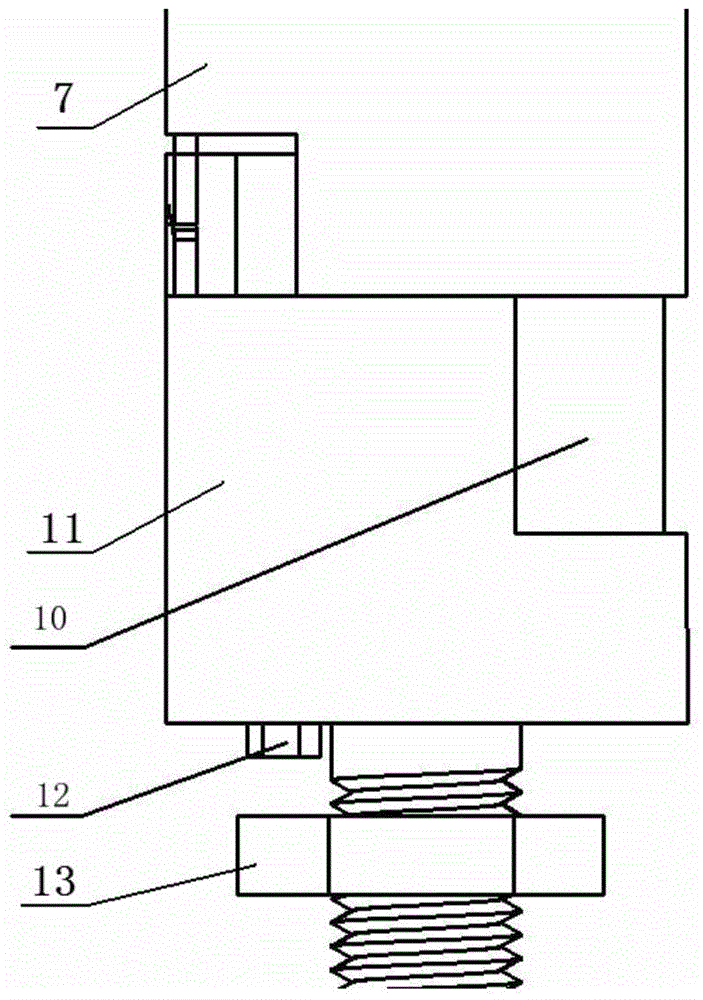

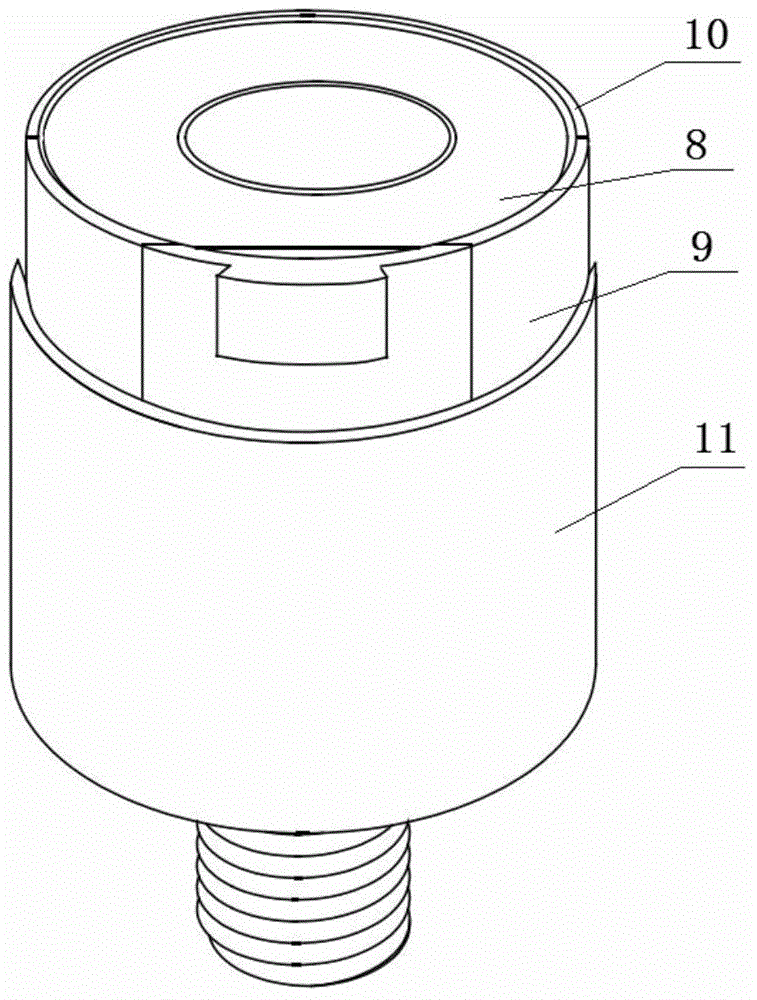

[0026] Specific implementation mode one: combine Figure 1 to Figure 13 Describe the implementation mode. This embodiment includes the back tightening nut 1 of the punch seat, the punch seat 2, the positioning pin of the punch 3, the punch 5, the blank holder nut 6, the blank holder lock 7, the blank holder ring 8, the split type Fixed semi-die 9, split-type dynamic semi-die 10, die base 11, die base back tightening nut 13, two die positioning bolts 12 and four punch positioning bolts 4, the punch base 2 consists of The bolt 2-1 is composed of the upper drum 2-2, the bottom of the upper drum 2-2 is located above, and the upper bolt 2-1 is vertically arranged on the upper end of the upper drum 2-2 along the axis of the upper drum 2-2 , the side wall of the upper drum 2-2 is provided with a first positioning through hole 2-3 which is perpendicular to the axis and passes through the axis, and the side wall of the upper drum 2-2 is evenly arranged with four threaded holes 2 along ...

specific Embodiment approach 2

[0027] Specific implementation mode two: combination Figure 5 , Figure 8 and Figure 9 To describe the embodiment, the difference between the inner diameter of the cylinder A and the outer diameter of the punch 5 in this embodiment is the thickness of one blank 14 to be drawn. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0028] Specific implementation mode three: combination Figure 4 The embodiment will be described. In this embodiment, the upper bolt 2-1 and the upper drum 2-2 are integrally formed. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com