Band steel surface defect feature extraction and classification method

A technology of feature extraction and classification method, which is applied in the direction of instruments, character and pattern recognition, computer components, etc., and can solve the problems of classification accuracy and efficiency conflicts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

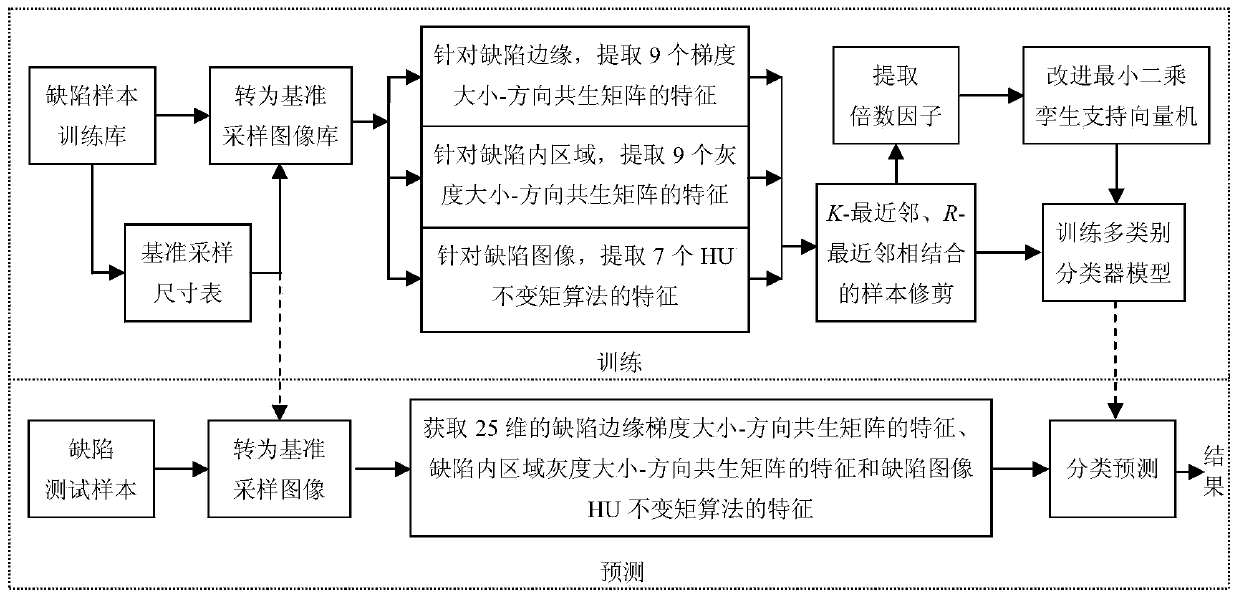

[0088] The embodiment of the present invention adopts a feature extraction and classification method for steel strip surface defects to process the defects of the steel strip, and the process is as follows figure 1 shown, including the following steps:

[0089] Step 1: Extract the reference sampling size table of the strip steel surface defect sample database;

[0090] The reference sampling size table is obtained on the basis of analyzing the training sample library of strip surface defects, which can avoid the influence of scale on the feature extraction of defect samples. The training library in the embodiment of the present invention is a sample extracted from the strip surface defect detection system on site, and contains six types of defect sample sets, which are: cracks, scars, holes, scale, curling and scratches .

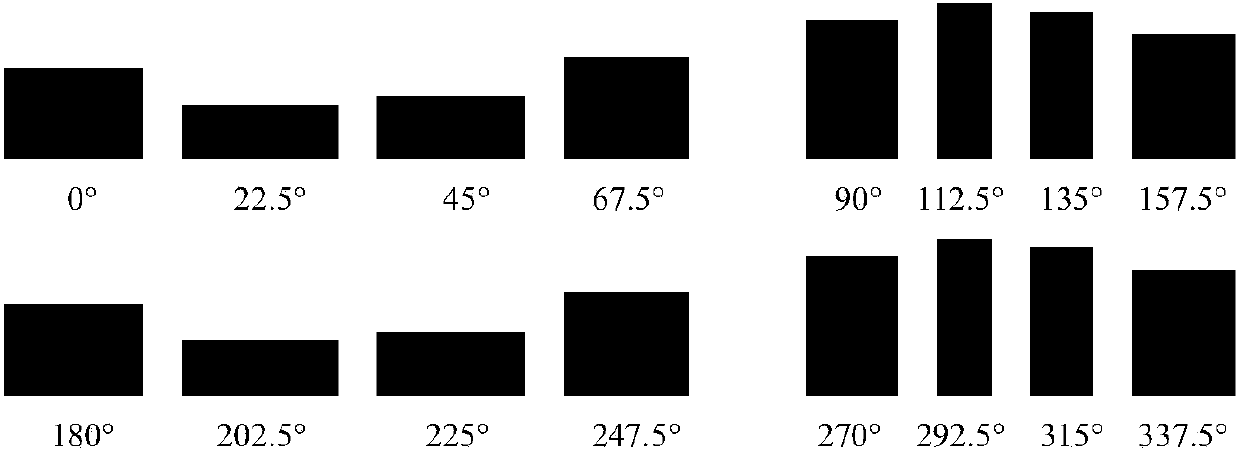

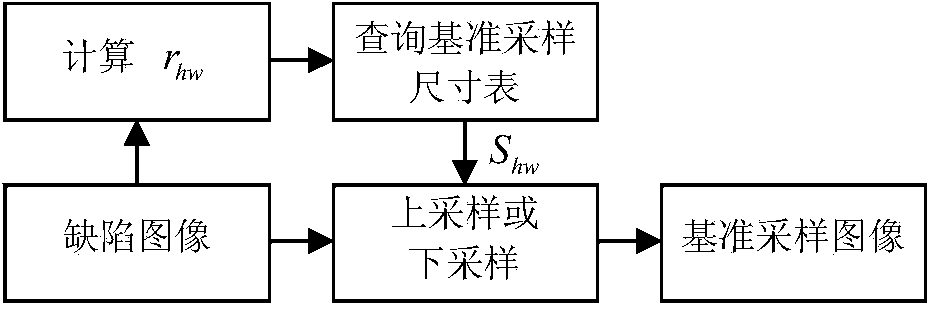

[0091] Step 1-1: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com