Riveting mechanism of riveting square jig

A riveting mechanism and square riveting technology, applied in the direction of connection, electrical components, circuits, etc., can solve the problems of slow return speed of gold needle riveted plate, increase of equipment manufacturing cost, and elongation of gold needle length, and achieve simple structure and low manufacturing cost , Extrusion effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

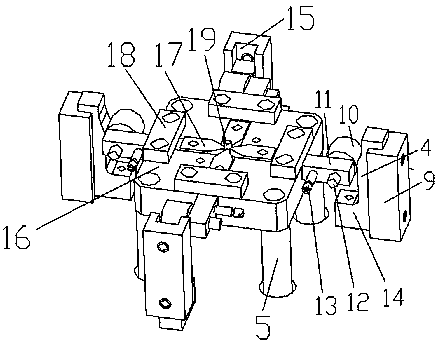

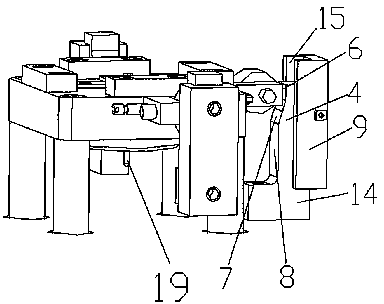

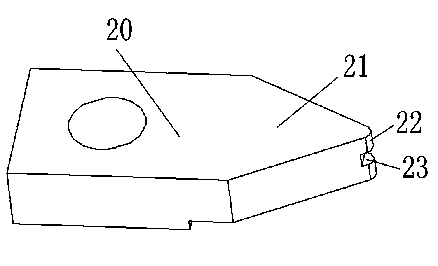

[0018] Such as Figure 1-3 As shown, a riveting mechanism for a riveted square jig includes a placing plate 16, four riveting plates 17, a baffle plate 9, a cam roller 10, a sliding arm 4, an extension spring and a moving block 11, and the four placing plates 16 Each corner is connected and supported by support columns 5 respectively. An opening for placing gold needles 19 is provided at the center of the placement plate 16, and a slideway is respectively provided around the opening, and the riveting plate 17 is arranged in the slideway, and a stopper is respectively provided on the four sides of the placement plate 16. Plate 9, a chute 15 is provided in the baffle plate 9, the sliding arm 4 is arranged in the chute 15, and can slide along the chute 15, the cam roller 10 is in sliding contact with the sliding surface of the sliding arm 4 and A displacement in the hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com