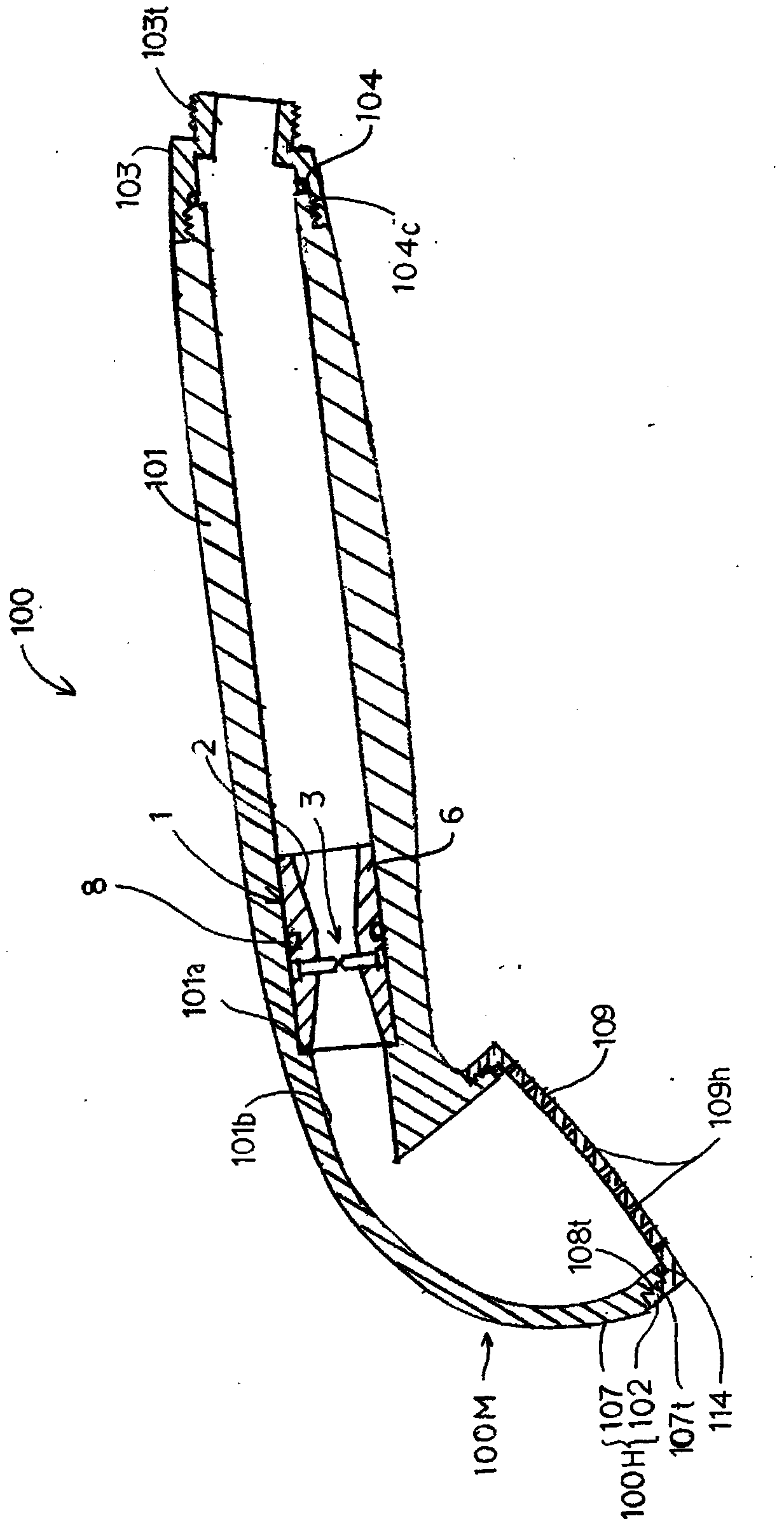

Bubble generating mechanism and showerhead with bubble generating mechanism

A technology for generating bubbles and components, which is applied in mixers, injection devices, sanitary equipment, etc., and can solve problems such as increased fluid resistance, insufficient bubble precipitation, and insufficient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

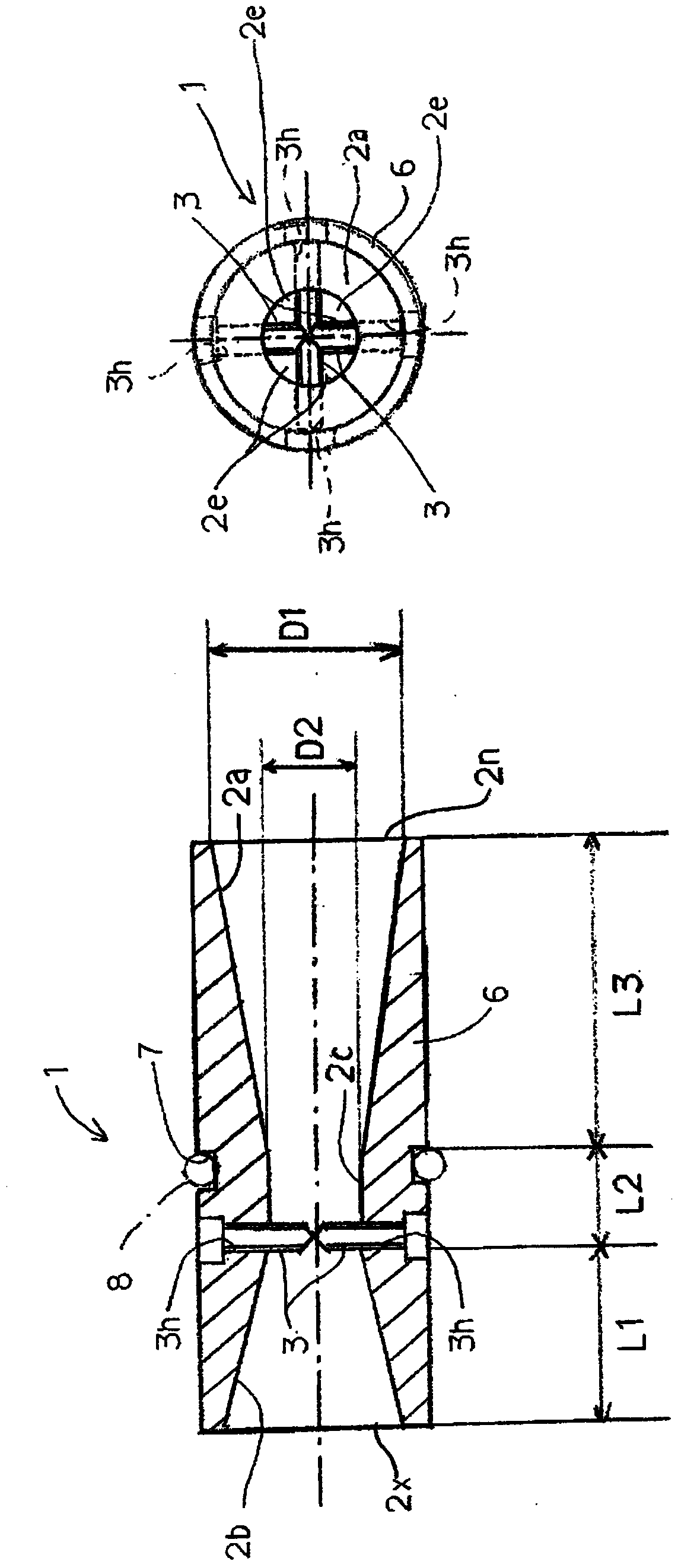

[0102] Prepare to specify in the following way figure 2 The specific size of the flow path and conflicting parts of the bubble generator 2.

[0103] ( image 3 )

[0104] ・Inflow port 2n and outflow port 2x: inner diameter = 16mm

[0105] ・Inflow side tapered part 2a: flow path length L3=24mm

[0106] ・Outflow side tapered part 2b: flow path length L1=16mm

[0107] ·Reduced diameter part 2c: inner diameter D2=8mm, flow path length L2=8mm

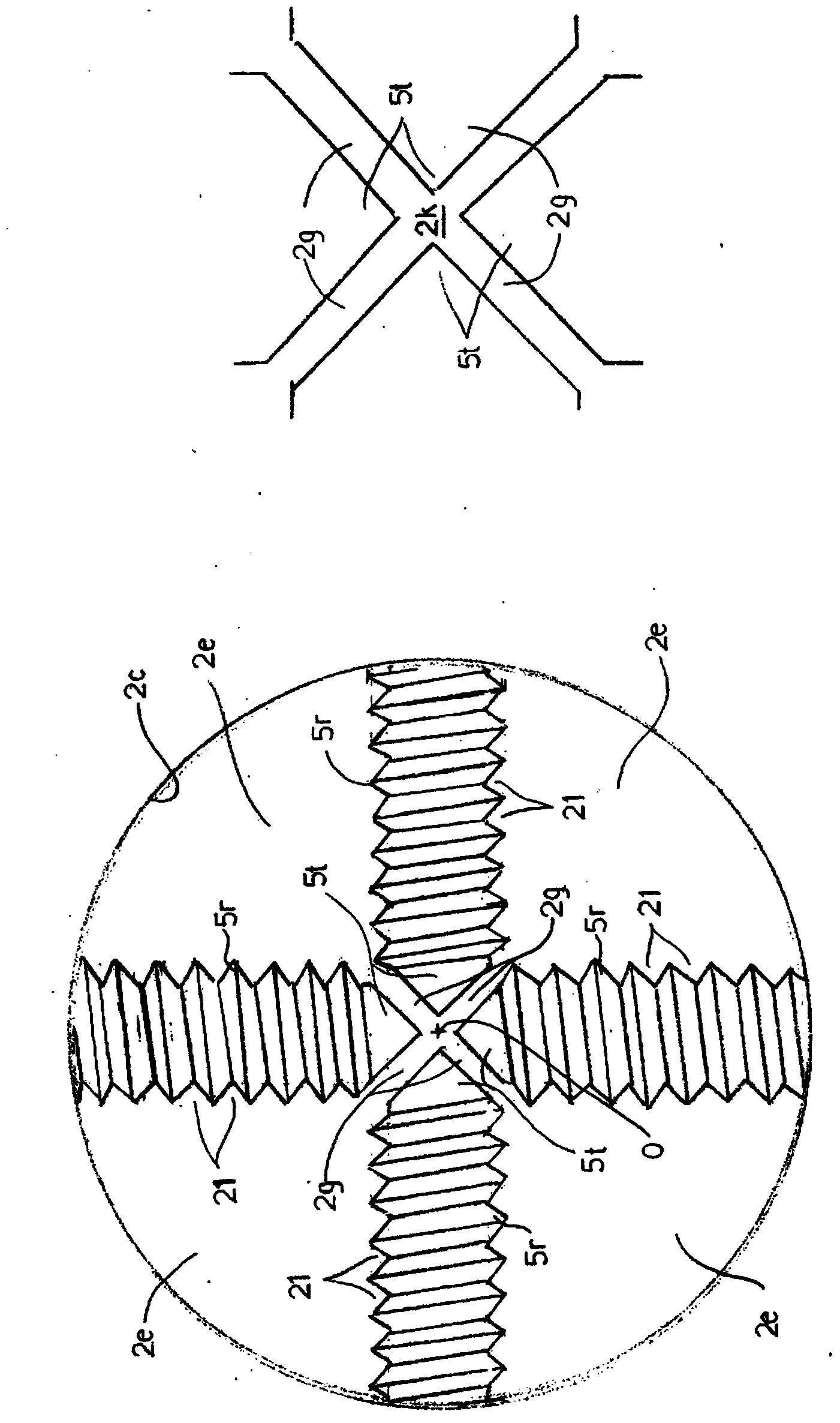

[0108] Conflict part 3: Thread outer diameter: M2, the front end is a sharp point with a front end angle of 90° after cutting a section including the axis

[0109] The size of the central gap 2k (the length between the sharp points of the opposing conflicting parts 3): three conditions of 0mm, 0.18mm and 0.36mm

[0110] A hose was connected to the bubble generator 2, water at 10° C. was supplied to the inflow port 2n at a supply pressure of 0.12 MPa, and the sprayed water was discharged into a water tank with a volume of about 90 lite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com