Deep nitrogen-removing technology based on SBR

A technology of deep denitrification and process, which is applied in the field of deep denitrification process based on SBR, can solve the problems that total nitrogen and total phosphorus are difficult to meet the emission standards, so as to improve the effect of phosphorus removal, improve the removal rate of total nitrogen, and enhance the accumulation of nitrogen. The effect of phosphorus bacteria activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

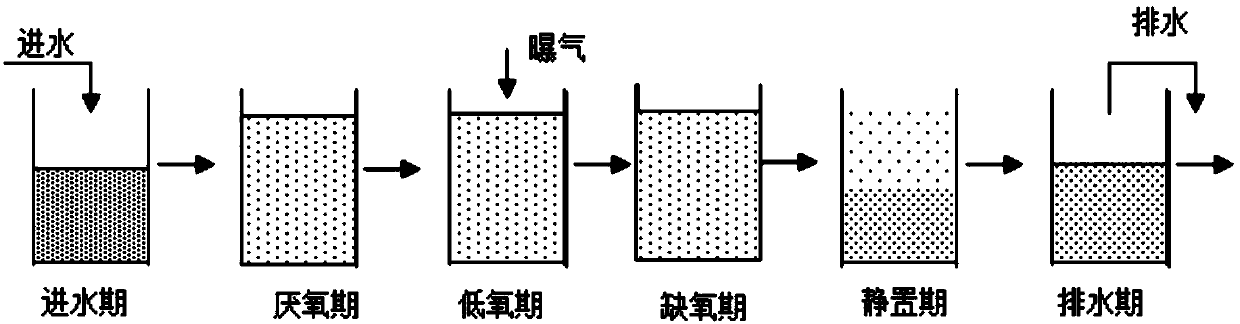

[0023] Combine below figure 1 The process flow of the present invention is further described in detail, which is an explanation of the present invention rather than a limitation.

[0024] like figure 1 , the deep denitrification process based on SBR of the present invention, the complete flow process of a cycle comprises the following steps:

[0025] Step 1: Pump the sewage to be treated into the SBR reactor. The general domestic sewage water quality indicators are: chemical oxygen demand COD = 300 ~ 500mg / L, biochemical oxygen demand BOD 5 =180~300mg / L, total nitrogen TN=60~80mg / L, ammonia nitrogen=40~60mg / L, total phosphorus TP=5~10mg / L. According to the capacity of the equipment, stop after reaching the predetermined water filling volume;

[0026] Step 2: Turn on the agitator to make the sewage in the SBR reactor run according to the mode of anaerobic → low oxygen → anoxic; the anaerobic mode is generally set for 1 to 2 hours, and then enter the low oxygen mode for aerat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com