Bio-treatment method for dephosphorization and denitrogenation of sewage

A biological treatment and denitrification technology, applied in the field of biological treatment of sewage phosphorus and nitrogen removal, can solve problems such as the reduction of denitrification and phosphorus removal efficiency, and achieve the effects of improving oxygenation efficiency, short residence time, and reducing oxygen consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

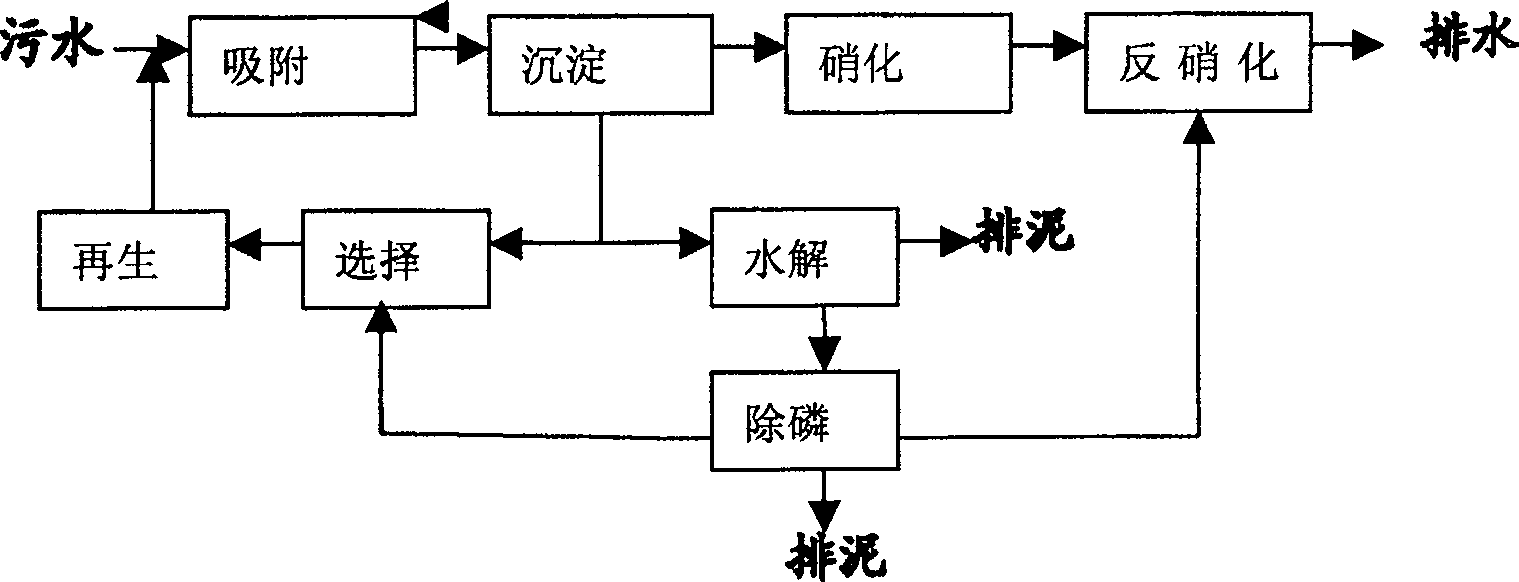

[0029] See figure 1 .

[0030] The system consists of adsorption tank, sedimentation tank, regeneration tank, selection tank, dephosphorization tank, nitrification tank, denitrification tank and hydrolysis acidification tank. Sewage enters the adsorption tank first, mixes with the sludge returned from the regeneration tank, and is removed by adsorption and other processes The particulate pollutants in the sewage are aerated with an aerator to make the dissolved oxygen concentration of the adsorption tank 0.2-0.5mg / l, and the sewage retention time is 45 minutes. The mixed liquid is discharged from the adsorption tank to the sedimentation tank. The retention time of the sedimentation tank is 2 hours to realize the separation of mud and water. The supernatant enters the biological aerated filter for nitrification, and then enters the denitrification biological aerated filter to achieve denitrification. The residence time is respectively 1 hour and 1.5 hours. 70% of the sludge discha...

Embodiment 2

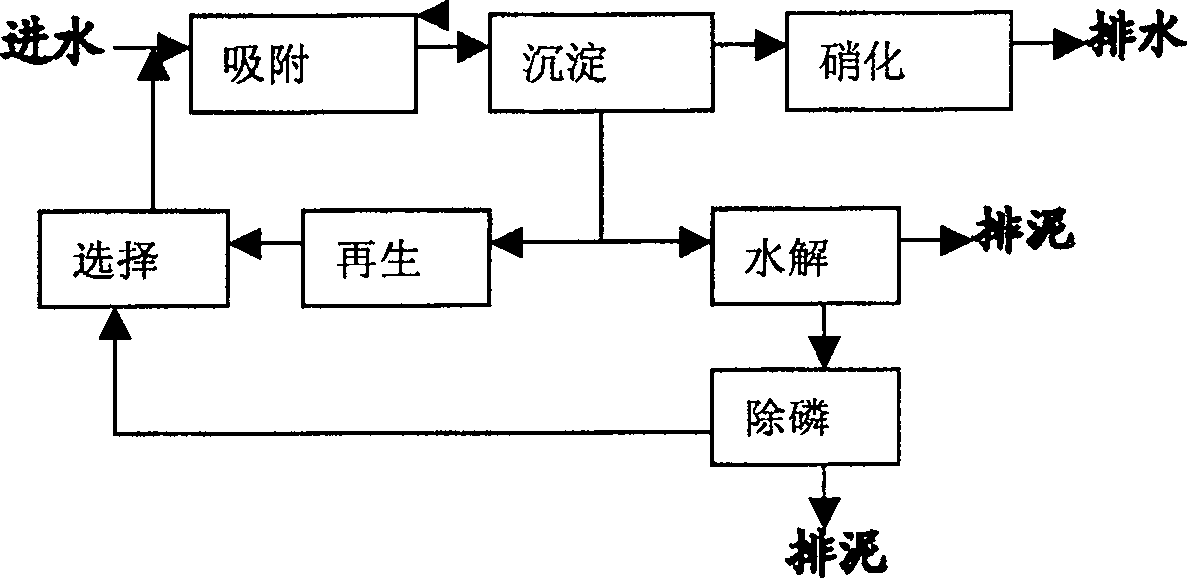

[0032] See figure 2 .

[0033] The system consists of adsorption tank, sedimentation tank, regeneration tank, selection tank, dephosphorization tank, nitrification tank and hydrolysis acidification tank. Sewage enters the adsorption tank first, mixes with the sludge returned from the selection tank, and removes particles in the sewage through adsorption and other processes For pollutants, use an aerator to aerate, so that the dissolved oxygen concentration in the adsorption tank is 0.2-0.5mg / l, and the sewage retention time is 45 minutes. The mixed liquid is discharged from the adsorption tank to the sedimentation tank. The retention time of the sedimentation tank is 2 hours to realize the separation of mud and water. The supernatant enters the biological aerated filter for nitrification. The retention time is 1 hour, and the effluent is directly discharged into the natural water body. The remaining sludge, which accounts for 70% of the total sludge discharged from the sedimentat...

Embodiment 3

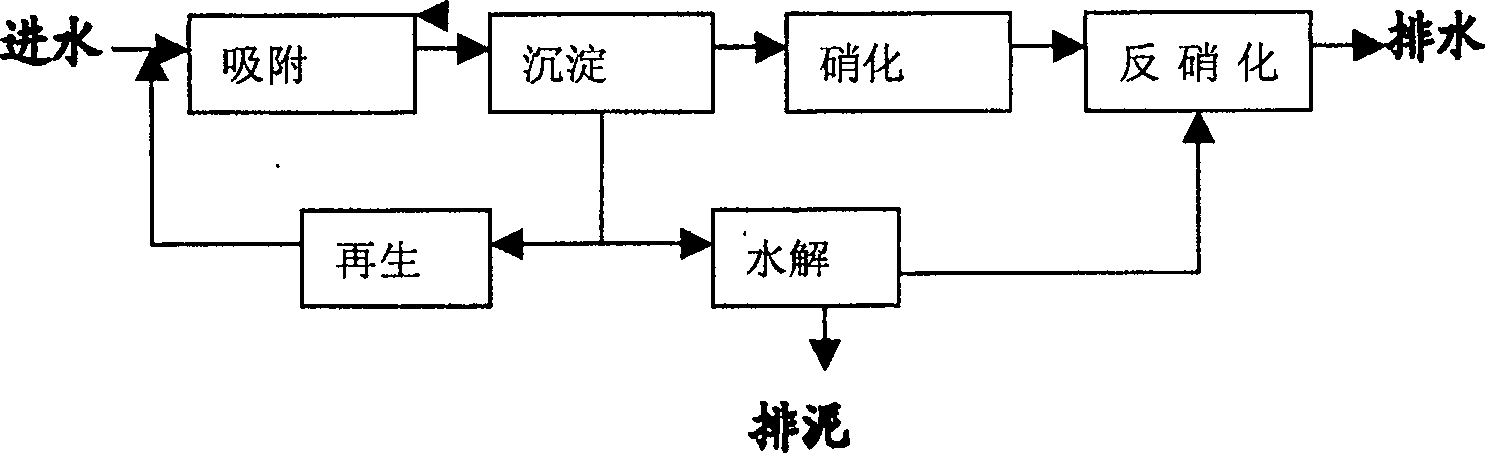

[0035] See image 3 .

[0036] The system is composed of adsorption tank, sedimentation tank, regeneration tank, nitrification tank, denitrification tank and hydrolysis acidification tank. Sewage enters the adsorption tank first, mixes with the sludge returned from the regeneration tank, and removes particulate pollutants in the sewage through adsorption and other processes. Adopt an aerator to aerate, so that the dissolved oxygen concentration of the adsorption tank is 0.2-0.5mg / l, and the sewage retention time is 45 minutes. The mixed liquid is discharged from the adsorption tank to the sedimentation tank. The retention time of the sedimentation tank is 2 hours to realize the separation of mud and water. The supernatant enters the biological aerated filter for nitrification, and then enters the denitrification biological aerated filter to achieve denitrification. The residence time is respectively 1 hour and 1.5 hours. 70% of the sludge discharged from the sedimentation tank ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com