Fixed carrier-supported biofilm and activated sludge coupled sequencing sewage treatment device and process

A sewage treatment device and activated sludge technology, applied in biological treatment devices, biological water/sewage treatment, water/sludge/sewage treatment, etc. Weak capacity and other problems, to achieve the effects of rapid drop in dissolved oxygen concentration, reduction of treatment and disposal costs, and ease of treatment and disposal pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

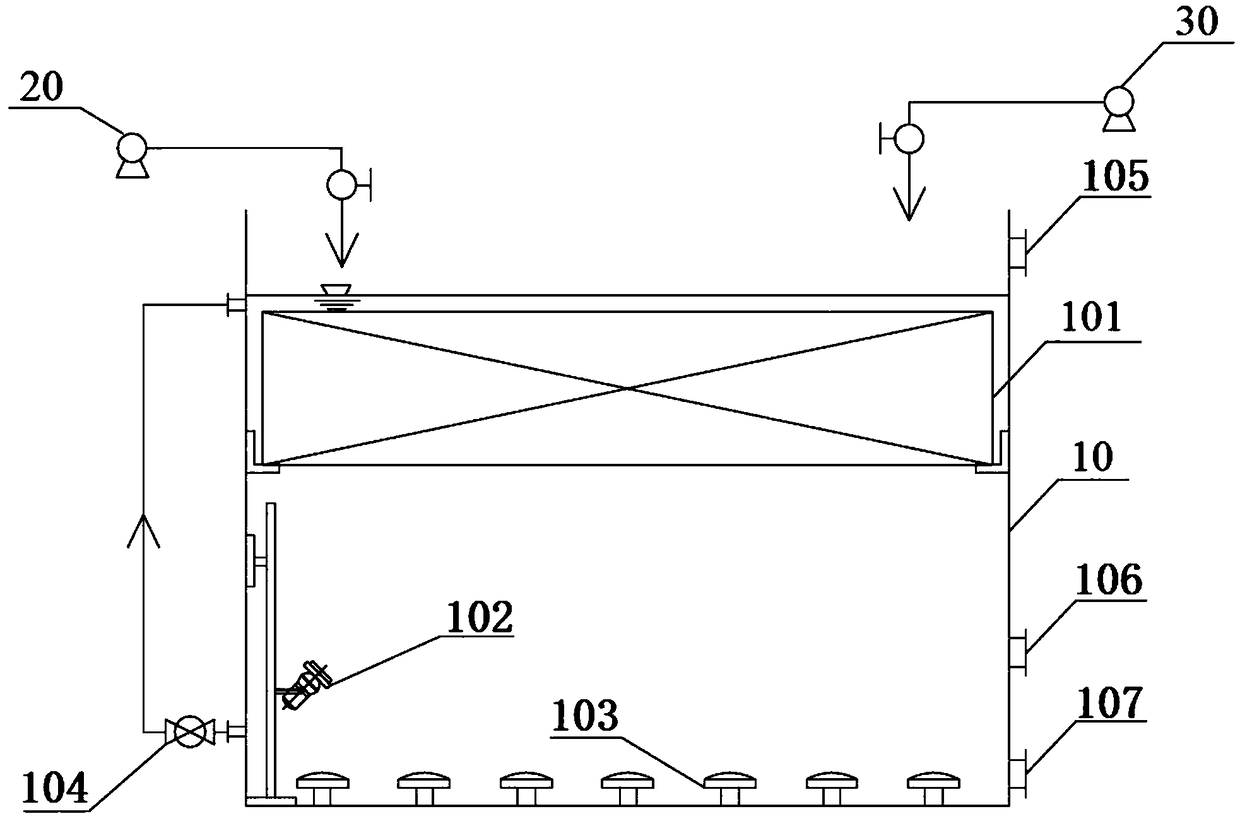

[0061] Make a sequence batch sewage treatment device coupled with fixed carrier biofilm and activated sludge (such as figure 1 As shown, the processing scale is about 120 tons / day).

[0062] Using the sewage treatment device for sewage treatment includes the following steps:

[0063] 1) Pass the incoming sewage of a sewage treatment plant through the grille and grit chamber for pretreatment, and then use the water inlet device to fill the reaction device with sewage, and the water inlet time is 12 minutes;

[0064] 2) Turn on the stirring device and the reflux device, and anaerobically stir for 20 minutes;

[0065] 3) Turn off the stirring device and the reflux device, turn on the aeration device, and aerate for 155 minutes;

[0066] 4) Turn off the aeration device, turn on the stirring device and the reflux device, and stir for 175 minutes in the absence of oxygen;

[0067] 5) Turn on the aeration device, and turn on the dosing device to add polyaluminum chloride (addition...

Embodiment 2

[0079] Make a sequence batch sewage treatment device coupled with fixed carrier biofilm and activated sludge (such as figure 1 As shown, the processing scale is about 120 tons / day).

[0080] Using the sewage treatment device for sewage treatment includes the following steps:

[0081] 1) Pass the incoming sewage of a sewage treatment plant through the grille and grit chamber for pretreatment, and then use the water inlet device to fill the reaction device with sewage, and the water inlet time is 12 minutes;

[0082] 2) Turn on the stirring device and the reflux device, and anaerobically stir for 45 minutes;

[0083] 3) Turn off the stirring device and the reflux device, turn on the aeration device, and aerate for 120 minutes;

[0084] 4) Turn off the aeration device, turn on the stirring device and the reflux device, and stir for 210 minutes in the absence of oxygen;

[0085] 5) Turn on the aeration device, and turn on the dosing device to add polyaluminum chloride (addition...

Embodiment 3

[0096] Make a sequence batch sewage treatment device coupled with fixed carrier biofilm and activated sludge (such as figure 1 As shown, the processing scale is about 120 tons / day).

[0097] Using the sewage treatment device for sewage treatment includes the following steps:

[0098] 1) Pass the incoming sewage of a sewage treatment plant through the grille and grit chamber for pretreatment, and then use the water inlet device to fill the reaction device with sewage, and the water inlet time is 12 minutes;

[0099] 2) Turn on the stirring device and the reflux device, and anaerobically stir for 30 minutes;

[0100] 3) Turn off the stirring device and the reflux device, turn on the aeration device, and aerate for 175 minutes;

[0101] 4) Turn off the aeration device, turn on the stirring device and the reflux device, and stir for 175 minutes in the absence of oxygen;

[0102] 5) Turn on the aeration device, and turn on the dosing device to add polyaluminum chloride (addition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com