Plug flow type coupling sewage treatment device and process

A sewage treatment device, push-flow technology, applied in water/sewage treatment, biological water/sewage treatment, water/sewage treatment equipment, etc., can solve the problem of small environmental capacity, increased investment and operating costs, increased floor space, etc. It can alleviate the pressure of treatment and disposal, improve the denitrification capacity, and reduce the disposal cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

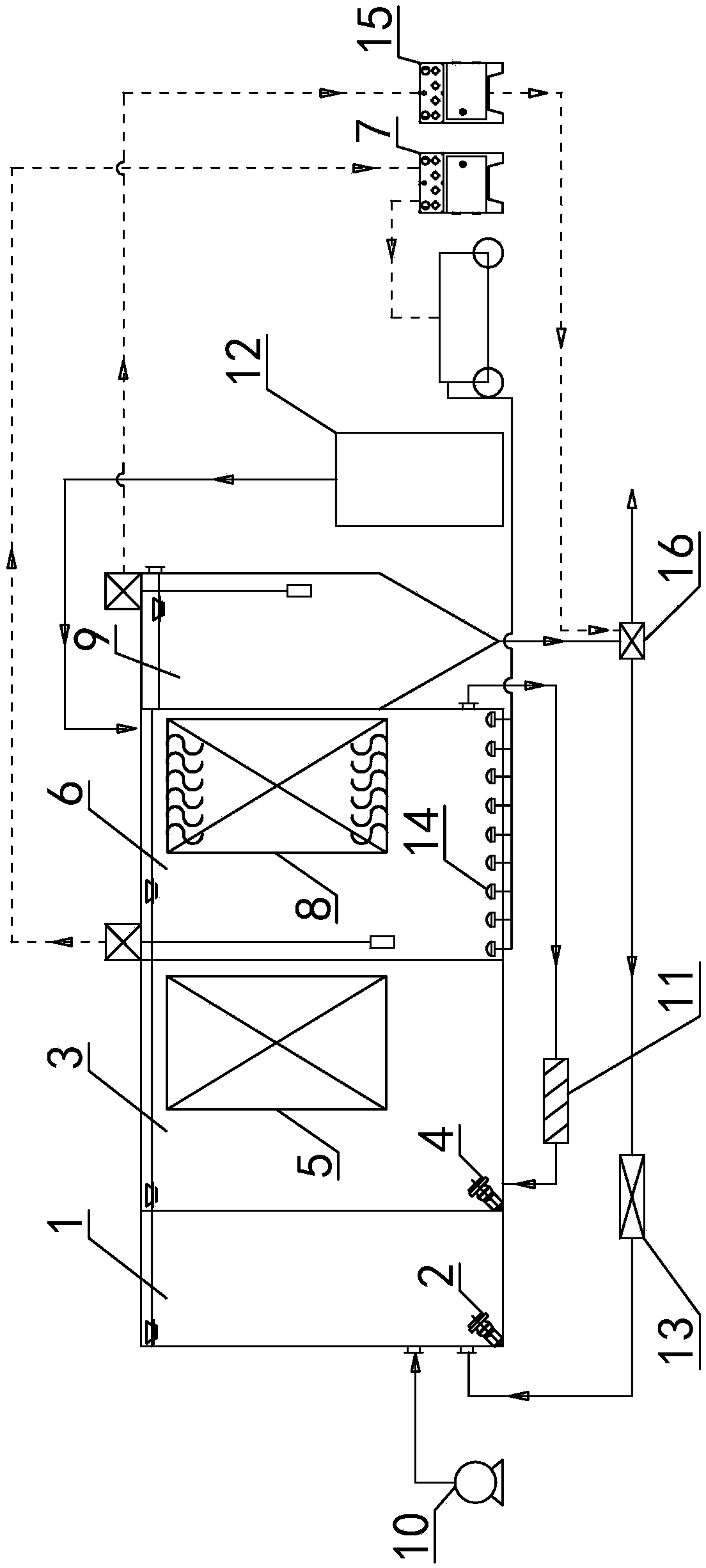

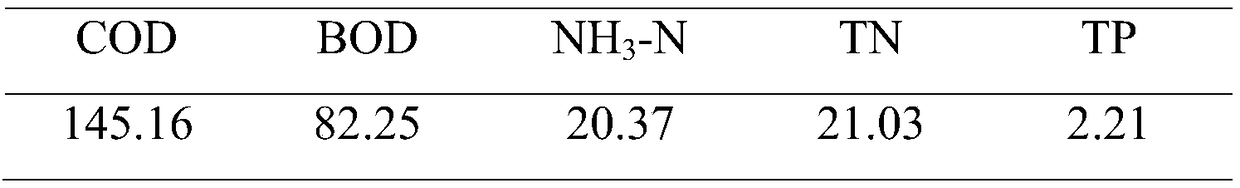

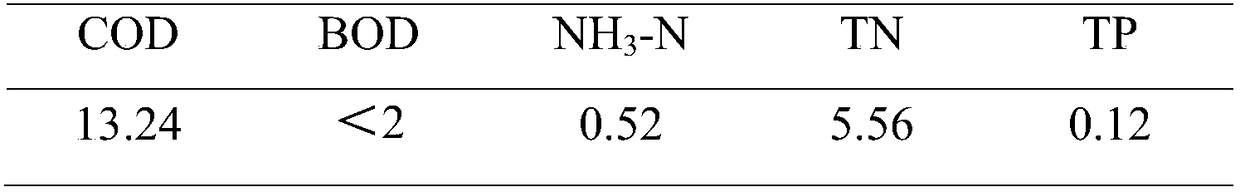

[0058] Make a kind of plug-flow coupling sewage treatment device of the present invention (referring to figure 1 , the processing scale is about 120 tons / day).

[0059] Use the sewage treatment device for sewage treatment, the operation steps are as follows:

[0060] 1) After removing the garbage and sediment from a sewage treatment plant in Guangzhou through the grille and grit chamber, the water inlet device 10 is used to transport the sewage to the anaerobic zone of the reaction device by submerging the water inlet at the lower end through the pipeline 1;

[0061] 2) Utilize the agitation effect of the agitation device 2 in the anaerobic zone to make the influent and return activated sludge in the anaerobic zone 1 sufficient, the hydraulic retention time of the anaerobic zone 1 is 1h, and the DO value is 0.15mg / L;

[0062] 3) The mud-water mixture in the anaerobic zone 1 flows into the anoxic zone 3 provided with a fixed biofilm carrier filler 5 by itself, and is transpor...

Embodiment 2

[0078] Make a kind of plug-flow coupling sewage treatment device of the present invention (referring to figure 1 , the processing scale is about 120 tons / day).

[0079] Using the sewage treatment device to treat sewage includes the following steps:

[0080] 1) After removing the garbage and sediment from a sewage treatment plant in Guangzhou through the grille and grit chamber, the water inlet device 10 is used to transport the sewage to the anaerobic zone of the reaction device by submerging the water inlet at the lower end through the pipeline 1;

[0081] 2) Utilize the stirring effect of the stirring device 2 in the anaerobic zone to make the influent and return activated sludge in the anaerobic zone 1 sufficient, the hydraulic retention time of the anaerobic zone 1 is 1h, and the DO value is 0.17mg / L;

[0082] 3) The mud-water mixture in the anaerobic zone 1 flows into the anoxic zone 3 provided with a fixed biofilm carrier filler 5 by itself, and is transported to the a...

Embodiment 3

[0099] Make a kind of plug-flow coupling sewage treatment device of the present invention (referring to figure 1 , the processing scale is about 120 tons / day).

[0100] Using the sewage treatment device to treat domestic sewage includes the following steps:

[0101] 1) After removing the garbage and sediment from a sewage treatment plant in Guangzhou through the grille and grit chamber, the water inlet device 10 is used to transport the sewage to the anaerobic zone of the reaction device by submerging the water inlet at the lower end through the pipeline 1;

[0102] 2) Utilize the stirring effect of the stirring device to make the water inflow and return activated sludge in the anaerobic zone 1 of the reaction device sufficient, the hydraulic retention time of the anaerobic zone 1 is 1h, and the DO value is 0.16mg / L;

[0103] 3) The mud-water mixture in the anaerobic zone 1 flows into the anoxic zone 3 provided with a fixed biofilm carrier filler 5 by itself, and is transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com