Device and process for preparing macromolecular aluminum salt coagulant by utilizing sludge of high-salinity wastewater zero discharge system

A high-salt wastewater and zero-discharge technology, which is applied in water/sludge/sewage treatment, water pollutants, water/sewage treatment, etc. Complex process and other issues, to achieve the effect of alleviating the pressure of sludge treatment and disposal, significant economic and environmental benefits, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

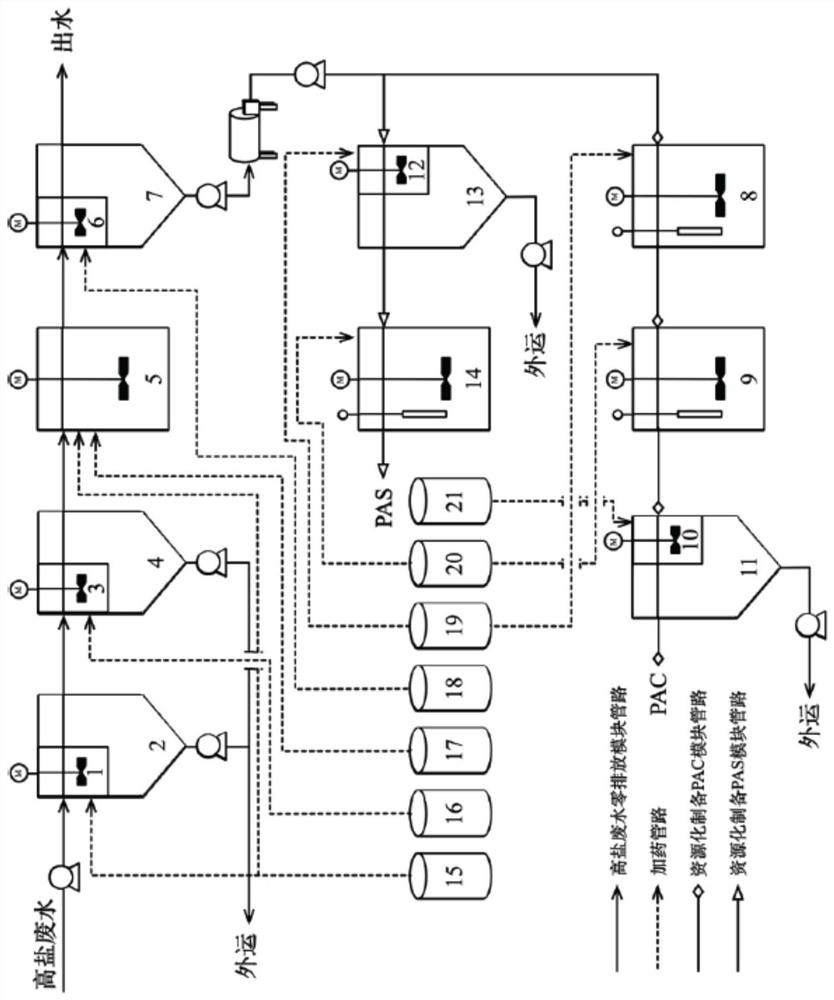

[0101] A process for preparing aluminum salt coagulant by recovering solid waste from high-salt wastewater with zero discharge, the process flow is as attached figure 1 As shown, it includes the zero-discharge process module of high-salt wastewater and the process module of solid waste recovery and preparation of aluminum salt coagulant.

[0102] The high-salt wastewater zero-discharge process module includes a high-salt wastewater inlet pump 22, a pre-sedimentation tank 1, a first sedimentation tank 2, a magnesium and sulfur removal tank 3, a second sedimentation tank 4, a chlorine removal reaction tank 5, and a chlorine removal tank. Settling tank 6, the third settling tank 7. The pre-sedimentation tank 1 is also connected with the calcium oxide dosing device 15, the magnesium and sulfur removal tank 3 is also connected with the magnesium and sulfur removal agent dosing device 16, and the chlorine removal reaction tank is also connected with the calcium oxide dosing device 1...

Embodiment 2

[0112] For a power plant flue gas desulfurization wastewater Ca 2+ , Mg 2+ , SO 4 2- and Cl - Concentrations are 1500, 1000, 3000 and 5000mg / L respectively, after treatment, Ca 2+ 2+ 4 2- - <2500mg / L, the indicators of PAC prepared by the production of chlorine-removing sediment must meet the requirements of the national standard GB / T22627-2014 for water treatment agents.

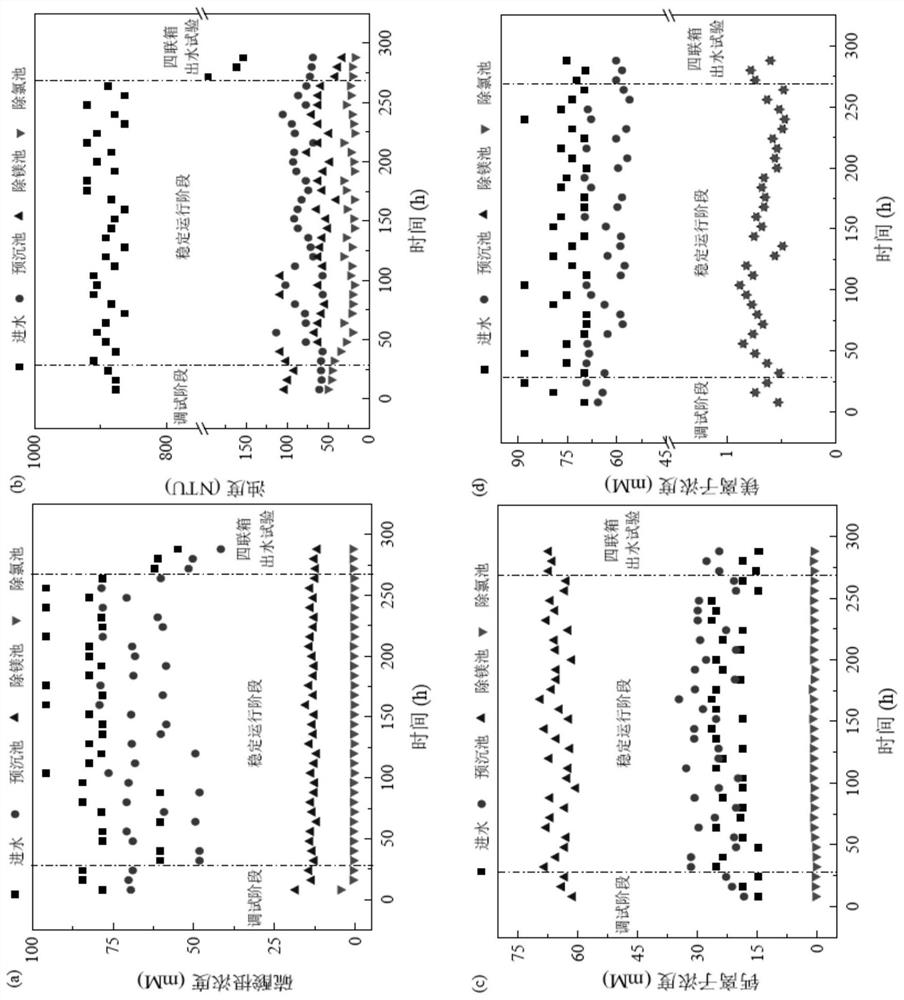

[0113] Based on the process in Example 1, a treatment water volume of 0.5m 3 / h productive demonstrative project, to process and productively demonstrate the actual flue gas desulfurization wastewater of a power plant. The operation of the process is divided into three stages, which run continuously for 16 days. The first stage is engineering commissioning, the second stage is to treat the raw water of desulfurization wastewater (2~12d), and the third stage is to treat the desulfurization wastewater of the power plant. (13~16d).

[0114] Such as image 3 and Figure 4 As shown, the concentration o...

Embodiment 3

[0135] A waste incineration power plant Ca 2+ , Mg 2+ , SO 4 2- , Cl - Concentrations of 2.4mg / L, 0.48mg / L, 1717.9mg / L, 5225.6mg / L of smoke washing wastewater, control Cl after treatment - Below 2600mg / L, the PAS produced by the recycling process of the compound salt precipitate formed by the removal of chloride ions must meet the national standard "Water Treatment Agent Polyaluminum Sulfate" (HG / T5006-2016).

[0136] This embodiment is substantially the same as Embodiment 2, but due to the low concentration of suspended solids and calcium and magnesium ions in the tobacco washing wastewater, the wastewater is directly discharged into the magnesium and sulfur removal pool 3 through the high-salt wastewater inlet pump 22 .

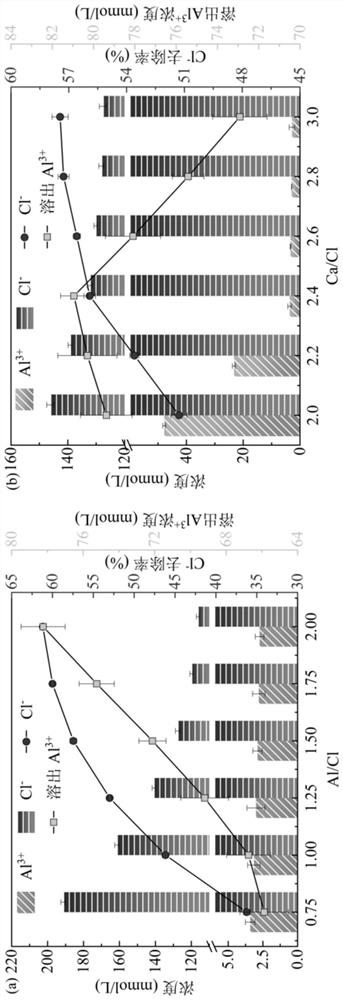

[0137] The sulfur removal agent used in the magnesium and sulfur removal tank 3 is calcium oxide, and the dosage is controlled at 3-6kg / m 3 . After the effluent is separated by the second sedimentation tank 4, the supernatant enters the chlorine remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com