Solid particle electrostatic separation device and method

A solid particle and electrostatic separation technology, applied in electrostatic separators, through electric/magnetic refining, etc., can solve the problems of frequent tripping, poor quality, complex composition of catalytic cracking oil slurry, etc., and achieve the effect of preventing frequent tripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

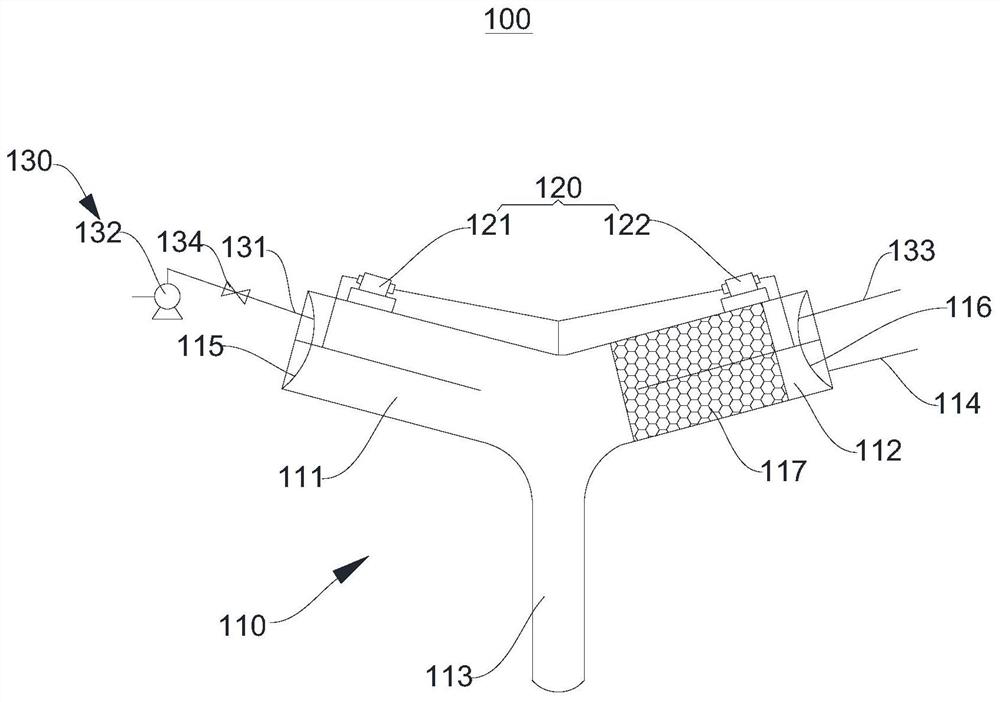

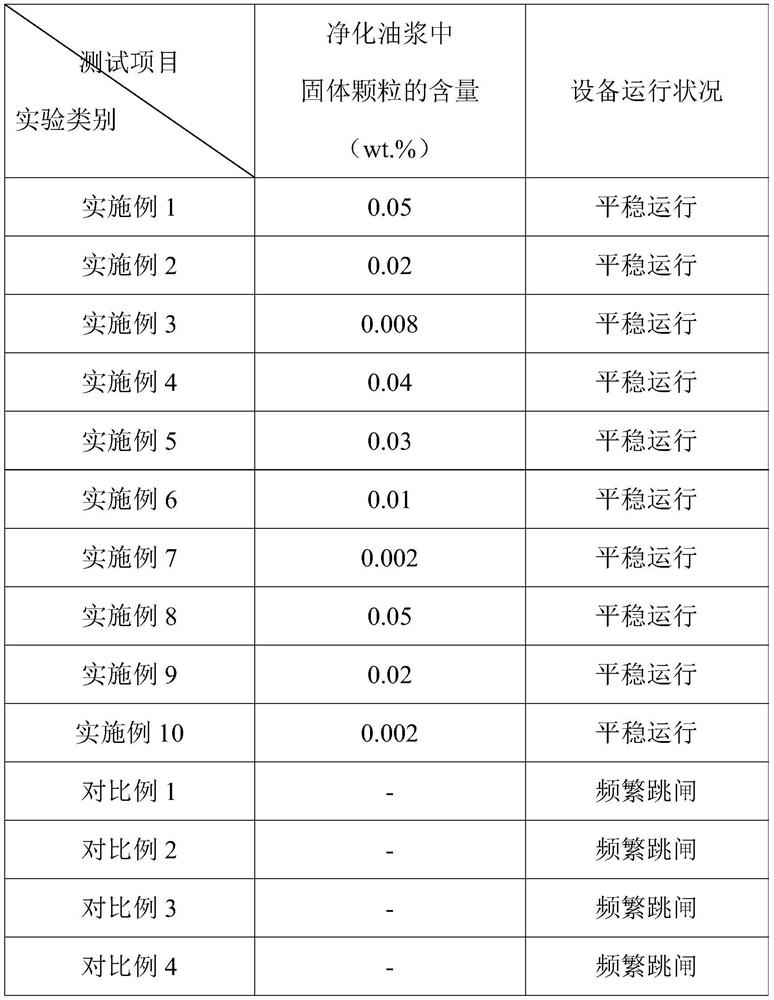

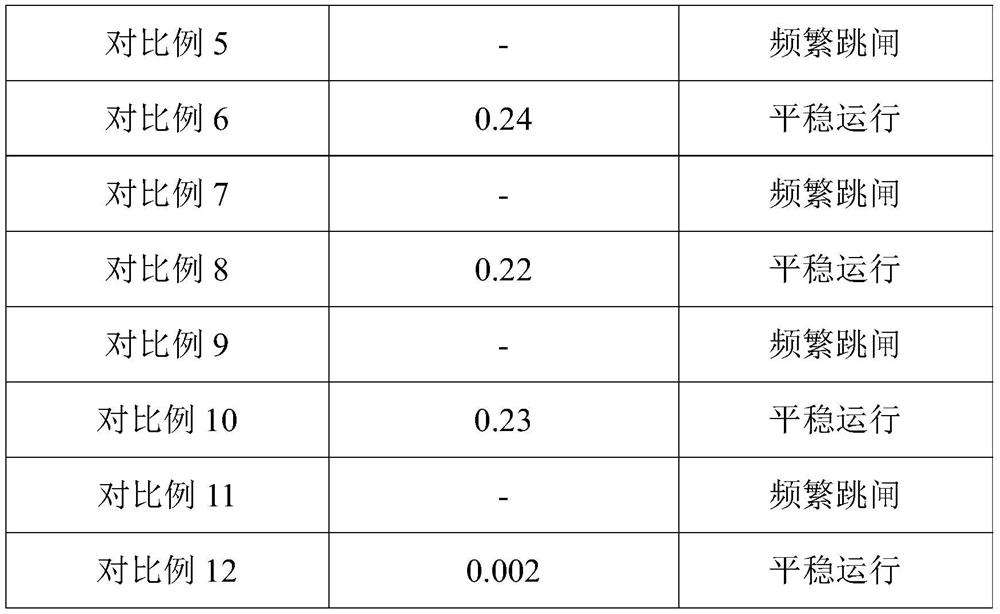

[0051] An electrostatic separation method for solid particles, comprising the following steps: heating the catalytic cracking oil slurry to 100°C, the heated oil slurry sequentially enters an AC pretreatment pipeline 111 with an electric field strength of 1000V / cm and an electric field strength of 1500V equipped with glass beads The solid particles are removed in the Y-type separation tank 110 of the straight-through deep treatment pipeline 112 of / cm. The oil slurry treated by the pretreatment pipeline 111 enters the waste material discharge pipeline 113 and accumulates in the waste material discharge pipeline 113, while the coalesced and grown solid particles in the treated oil slurry naturally settle along the pretreatment pipeline 111 to the waste material discharge In the pipeline 113, it is regularly discharged through the slag discharge port, and the purified oil slurry overflowing from the waste discharge pipeline 113 enters the advanced treatment pipeline 112 again. T...

Embodiment 2

[0053] An electrostatic separation method for solid particles, comprising the following steps: heating the catalytic cracking oil slurry to 100°C, the heated oil slurry sequentially enters a DC pretreatment pipeline 111 with an electric field strength of 10,000V / cm and a glass bead-equipped electric field with an electric field strength of 1000V The solid particles are removed in the Y-type separation tank 110 of the exchange depth treatment pipeline 112 at the exchange depth of / cm. The solid particles settled in the pretreatment pipeline 111 are naturally settled and discharged through the slag discharge port along the waste discharge pipeline 113 . Backwash the treatment tank every 2 hours. Cut off the power supply during the backwashing process. The oil sample after backwashing is discharged through the backwashing outlet. During backwashing, backup tanks are used to achieve continuous processing.

Embodiment 3

[0055] An electrostatic separation method for solid particles, comprising the following steps: heating the catalytic cracking oil slurry to 100°C, the heated oil slurry sequentially enters an AC pretreatment pipeline 111 with an electric field strength of 10,000V / cm and an electric field strength of 10,000V equipped with glass beads The solid particles are removed in the Y-type separation tank 110 of the straight-through deep treatment pipeline 112 of / cm. The solid particles settled in the pretreatment pipeline 111 are naturally settled and discharged through the slag outlet along the bottom of the tank. The area of the advanced treatment pipeline 112 is backwashed every 2 hours. Cut off the power supply during the backwashing process. The oil sample after backwashing is discharged through the backwashing outlet. During backwashing, backup tanks are used to achieve continuous processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com