Drying control method and device, clothes treatment equipment and storage medium

A technology for clothes processing equipment and drying control, which is applied to washing devices, household clothes dryers, textiles, and papermaking, etc. It can solve the problems of burning out plastic parts of the machine, tripping of thermostats, and damage to clothes, so as to prevent The effect of frequent tripping, reducing heat loss, and saving system energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

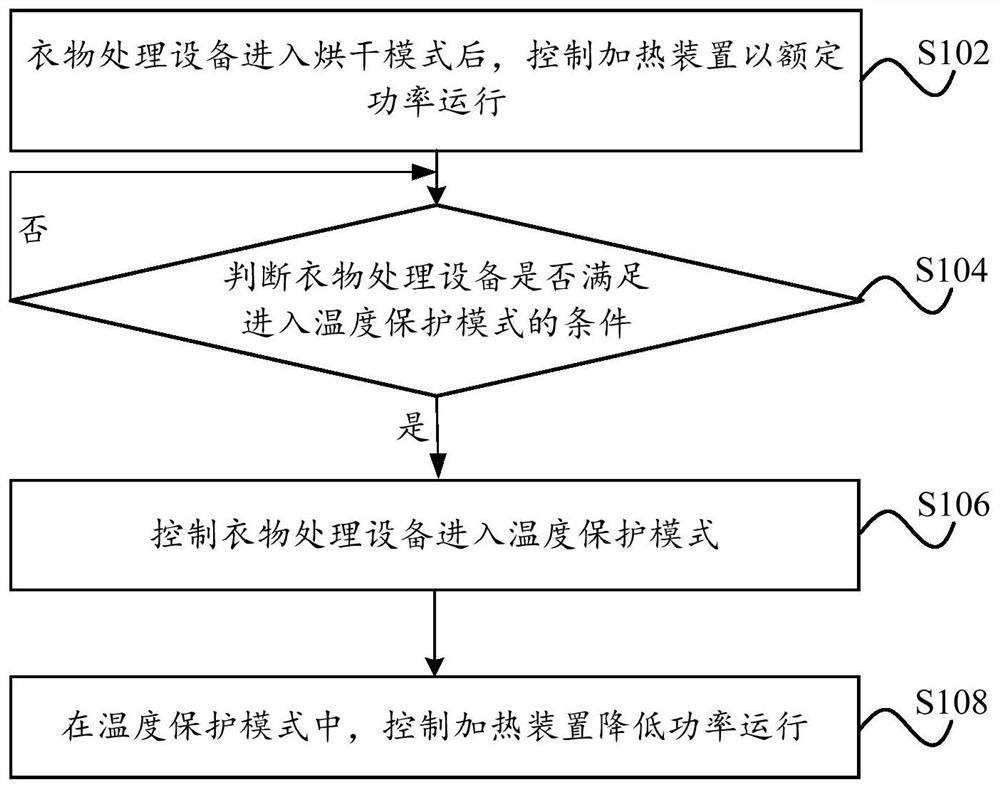

[0054] Such as figure 1 As shown, the drying control method provided by the technical solution of the first aspect of the present invention is suitable for clothes treatment equipment, and the drying control method includes:

[0055] Step S102: After the laundry processing device enters the drying mode, the heating device is controlled to operate at a rated power. Among them, the "rated power" is the full power of the heating device, that is, all the heating elements of the heating device are heated and operated at full load.

[0056] Step S104: Determine whether the clothes processing device meets the conditions for entering the temperature protection mode, if yes, execute step S106, if not, return to execute step S104.

[0057] Step S106: Control the laundry treatment device to enter the temperature protection mode. That is to say, turn on the temperature protection function.

[0058] Step S108: In the temperature protection mode, control the heating device to operate wit...

Embodiment 2

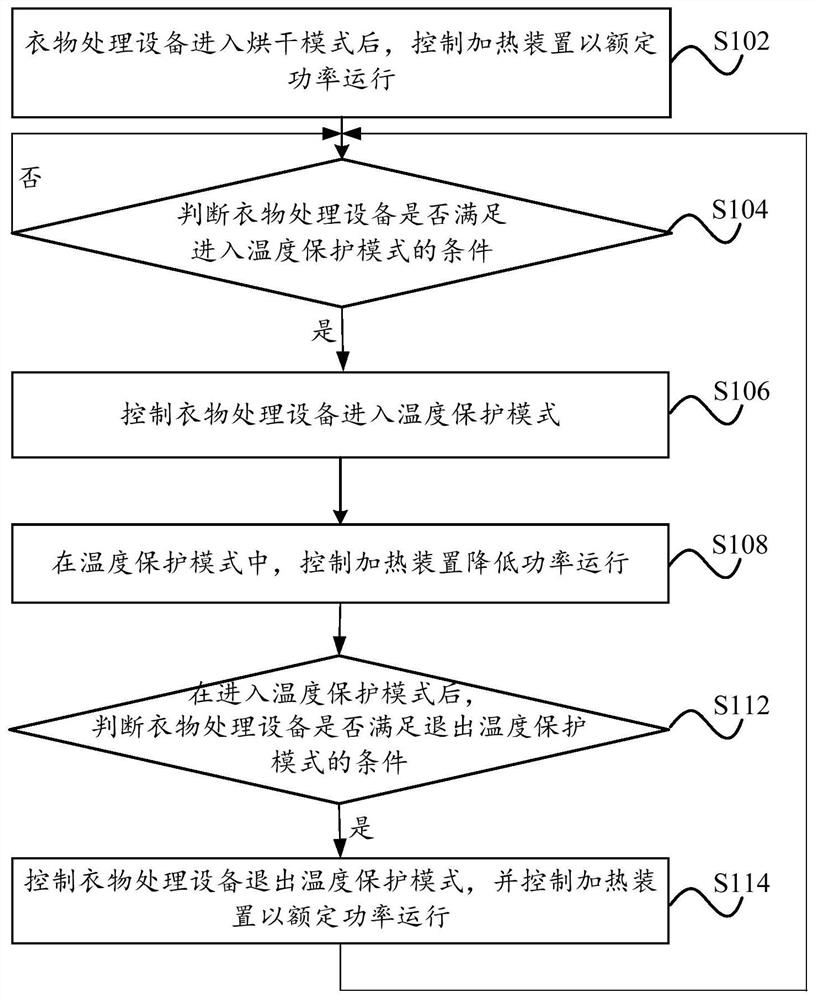

[0101] The difference with Embodiment 1 is: on the basis of Embodiment 1, further, as figure 2 As shown, step S10 specifically includes:

[0102] Step S112: After entering the temperature protection mode, determine whether the clothes processing device meets the conditions for exiting the temperature protection mode, and if so, execute step S114;

[0103] Step S114: Control the laundry treatment device to exit the temperature protection mode, and control the heating device to operate at the rated power, and return to step S104.

[0104] After entering the temperature protection mode, when it is detected that the clothes processing equipment meets the conditions for exiting the temperature protection mode, it indicates that the risk of high temperature has been removed, so the temperature protection mode can be exited, and the full power of the heating device (that is, the rated power of the heating device) can be resumed. , which can ensure the drying efficiency of the produ...

Embodiment 3

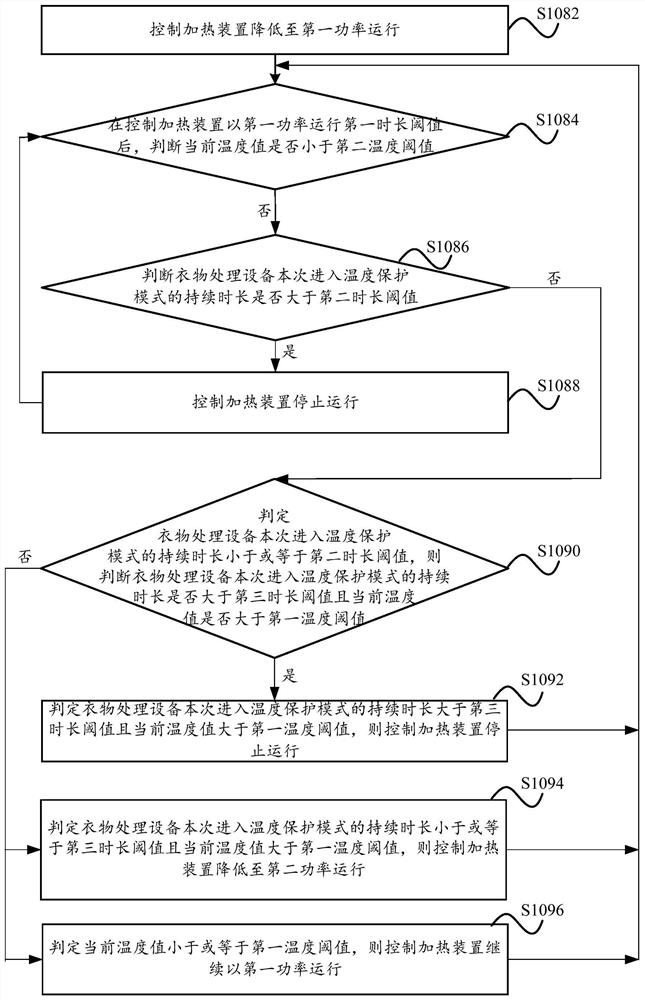

[0108] The difference with Embodiment 1 or Embodiment 2 is: on the basis of Embodiment 1 or Embodiment 2, further, as Figure 4As shown, the drying control method also includes:

[0109] Step S122: In the temperature protection mode, determine whether the current temperature value is greater than the third temperature threshold, if yes, execute step S124, if not, return to execute step S122;

[0110] Step S124: Determine that the current temperature value is greater than the third temperature threshold, then control the heating device to stop running.

[0111] Wherein, the third temperature threshold is greater than the first temperature threshold.

[0112] During the operation of the heating device with reduced power, if it is detected that the current temperature value is greater than the third temperature threshold, it indicates that there is a great risk of high temperature in the inner barrel, so no matter what heating state the heating device is currently in, the heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com