Waste acid resource recycling method

A resource-based, polluted acid technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of high disposal costs, loss and waste of acid resources, and many processing steps, so as to reduce the amount of hazardous waste , effective recycling, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

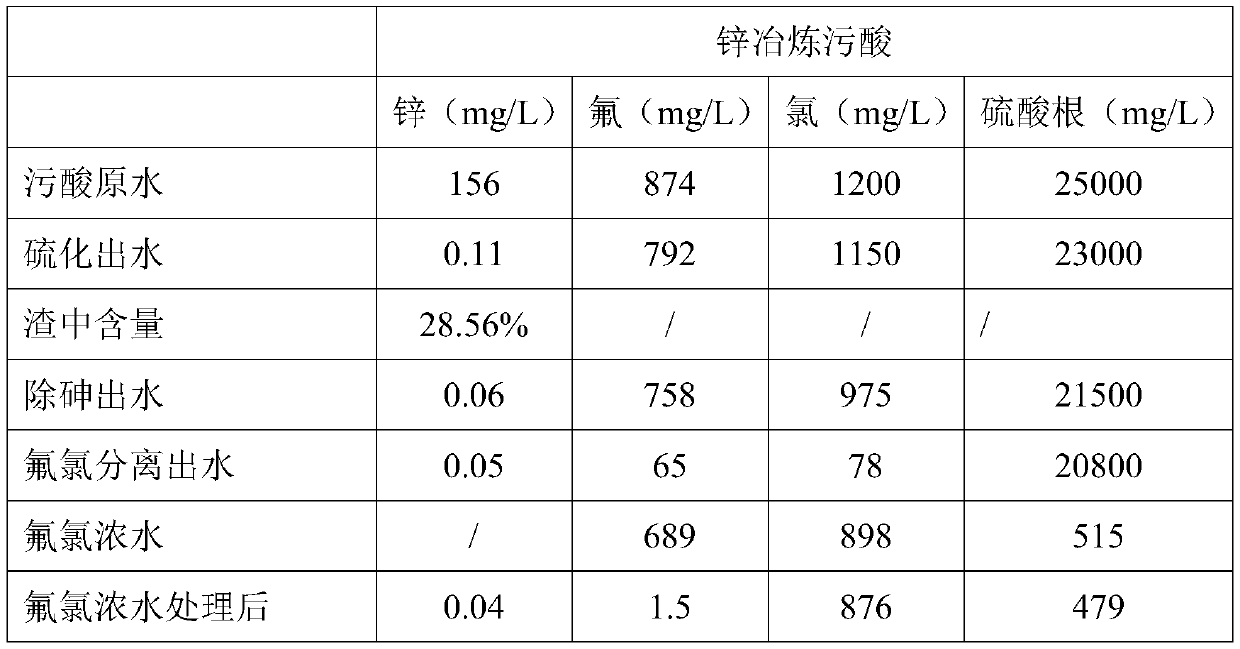

Embodiment 1

[0042] A method for resource recovery and treatment of polluted acid, said method comprising the following steps:

[0043] Step 1): Sodium hydrogen sulfide is added to the sewage acid, the ORP range is controlled to 250mv, the reaction time is 30 minutes, and then flocculated and precipitated by PAM, the precipitation time is 30 minutes, and the precipitated sludge can be used as ingredients for pyrometallurgy after pressure filtration. The polluted acid after recovery of valuable metals enters the next step of treatment.

[0044] Step 2): Continue to add sodium hydrosulfide to the pretreated sewage acid, control the ORP range to 100mv, and the reaction time is 30 minutes, then pass PAM flocculation and precipitation, the precipitation time is 60 minutes, and the precipitated sludge is treated as hazardous waste after pressure filtration Hand over to units with hazardous waste disposal qualifications for disposal, and the polluted acid after arsenic removal enters the next ste...

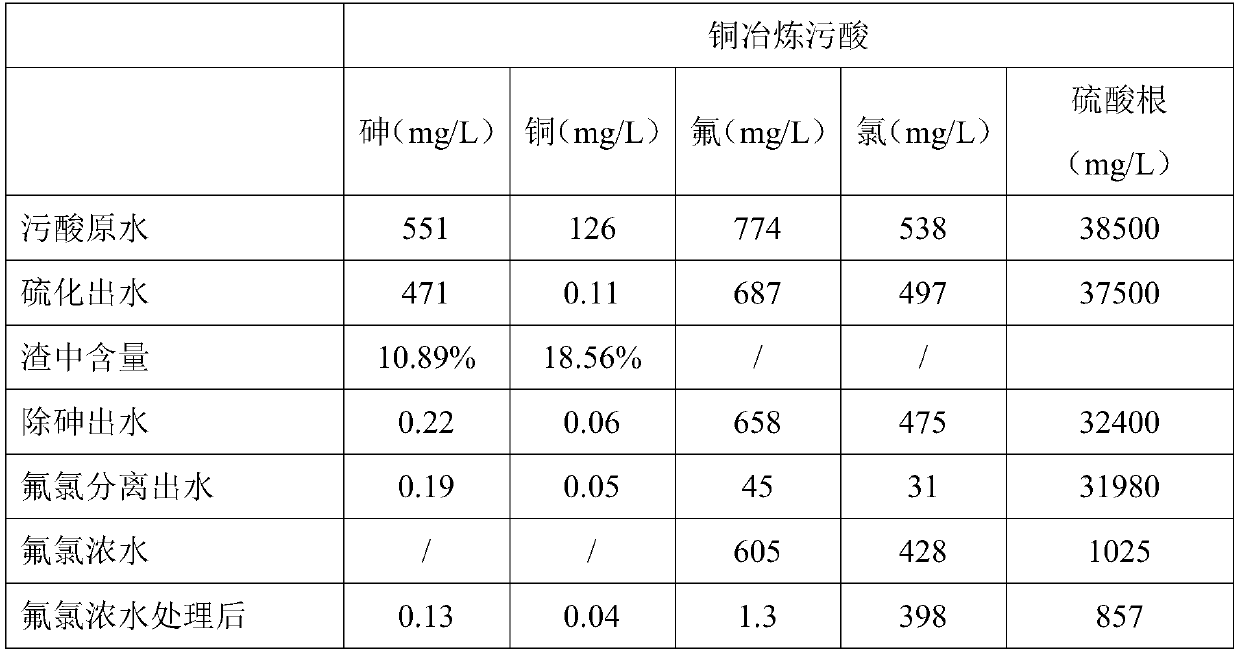

Embodiment 2

[0052] A method for resource recovery and treatment of polluted acid, said method comprising the following steps:

[0053] Step 1): Sodium hydrogen sulfide is added to the sewage acid, the ORP range is controlled to 350mv, the reaction time is 60 minutes, and then flocculated and precipitated by PAM, the precipitation time is 60 minutes, and the precipitated sludge can be used as ingredients for pyrometallurgy after pressure filtration. The polluted acid after recovery of valuable metals enters the next step of treatment.

[0054] Step 2): Continue to add sodium hydrosulfide to the pretreated sewage acid, control the ORP range to 200mv, and the reaction time is 60 minutes, then pass PAM flocculation and precipitation, the precipitation time is 30 minutes, and the precipitated sludge is treated as hazardous waste after pressure filtration Hand over to units with hazardous waste disposal qualifications for disposal, and the polluted acid after arsenic removal enters the next ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com