Rubbing type dropping bottle recycling device

A recycling device and drip bottle technology, applied in the field of medical devices, can solve the problems of endangering the personal safety of staff, batch positioning processing, difficult separation of paper labels, etc., and achieve the effect of avoiding mixed pollution in the later stage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

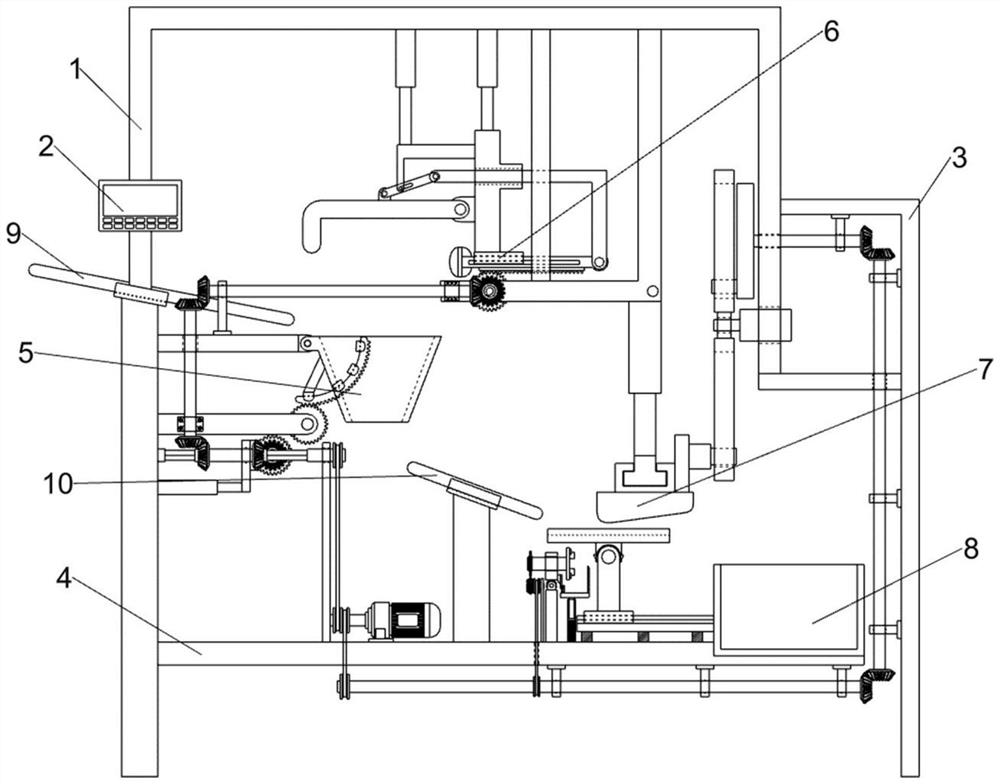

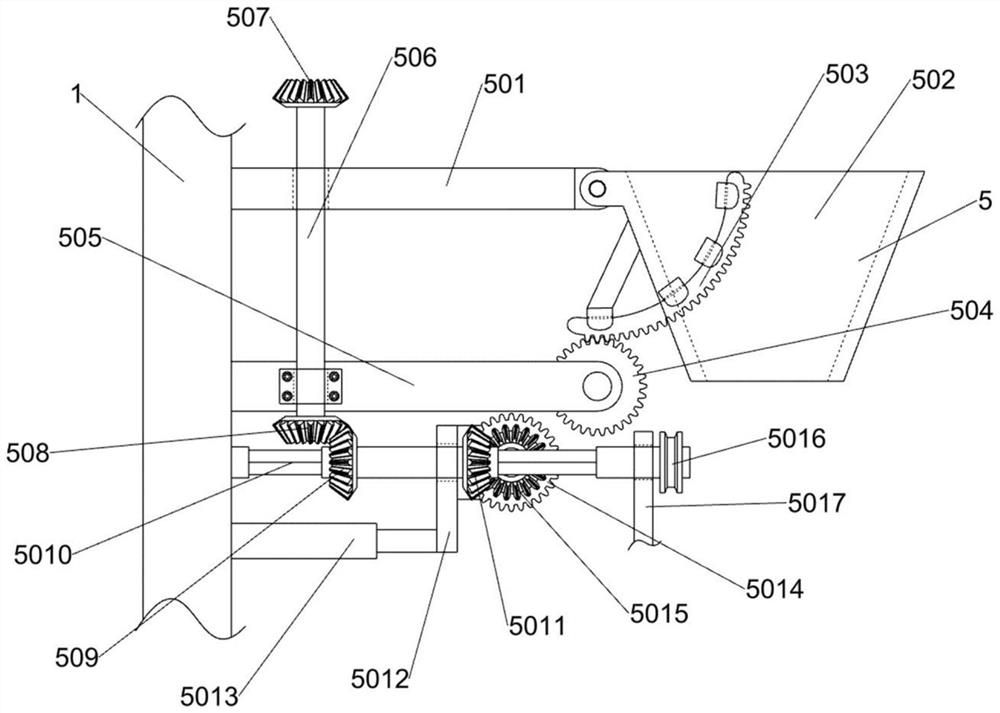

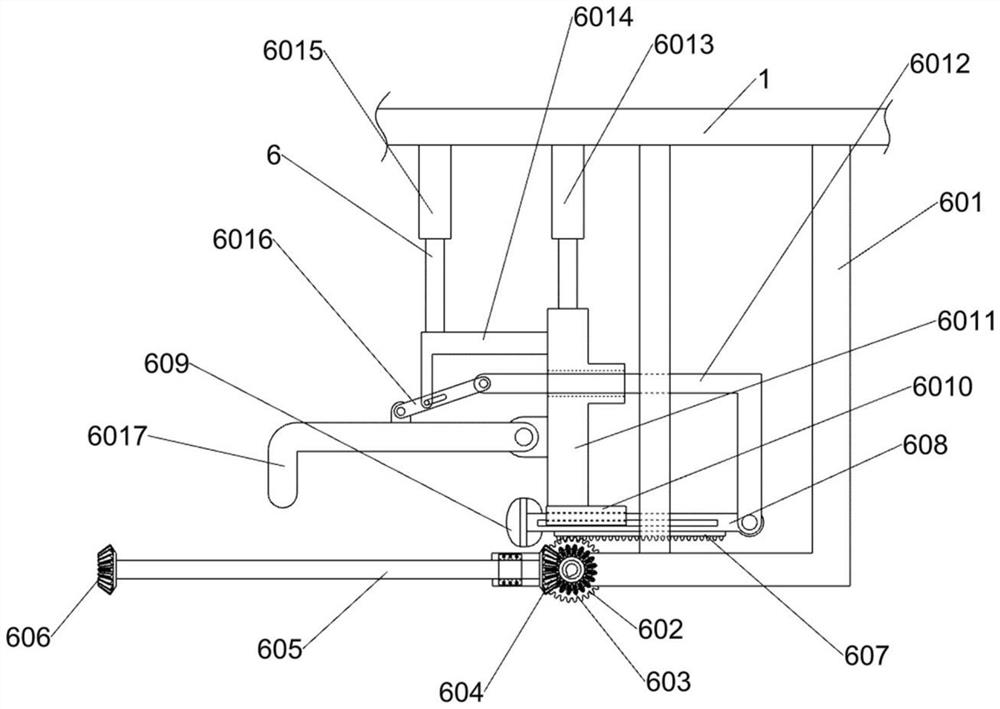

[0029] A rubbing type drop bottle recovery device, such as Figure 1-8 As shown, it includes a first frame plate 1, an operation control panel 2, a second frame plate 3, a bottom plate of the installation machine 4, a fixed flip transfer system 5, an extrusion spray system 6, a rubbing and demarking system 7, and a collection basket 8. The first sliding double rod 9 and the second sliding double rod 10; the first frame plate 1 is connected with the operation control panel 2; the first frame plate 1 is connected with the second frame plate 3; the first frame The plate 1 is connected with the bottom plate 4 of the installation machine; the bottom plate 4 of the installation machine is connected with the collection basket 8; the first frame plate 1 is connected with the first sliding double rod 9; the bottom plate 4 of the mounting machine is connected with the second sliding double rod 10 ; The first frame plate 1 is connected with the fixed overturn transfer system 5; the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com