Biomass modified sludge sintered brick and preparation method thereof

A technology of biomass and sintered bricks, which is applied in the field of solid waste resource utilization and building materials, which can solve the problems of difficult dehydration, difficulty in directly preparing sintered bricks, environmental hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

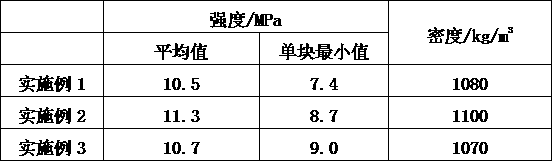

Examples

Embodiment 1

[0029] A preparation method of biomass modified sludge sintered bricks, comprising the following steps:

[0030] 1) Break the sawdust and straw into 0~3mm biomass particles.

[0031] 2) The calorific value of biomass particles is 2300kcal, and the calorific value of sludge is 700kcal. The mass percentage of biomass particles and sewage sludge is 10:90. After mixing and stirring, ferment for 5 days.

[0032] 3) The fermented mixture is mixed with the foundation pit soil at a mass ratio of 45:55, stirred evenly, and then entered into the aging warehouse for aging. The aging time is 1d.

[0033] 4) Crush the cinder into particles of 0~3mm, and mix and stir the aged mixture and cinder at a mass ratio of 85:15;

[0034] 5) The uniformly stirred billet is pressure-formed and the semi-hard extrusion process is used to make the billet, and the pressure is 2.3MPa;

[0035] 6) The green body enters the drying room and is dried for 2 hours at 200°C. ;

[0036] 7) The dried body enter...

Embodiment 2

[0038] A preparation method of biomass modified sludge sintered bricks, comprising the following steps:

[0039] 1) Break the sawdust and straw into 0~3mm biomass particles.

[0040] 2) The calorific value of biomass particles is 2000kcal, and the calorific value of sludge is 850kcal. The mass percentage of biomass particles and sewage sludge is 15:85. After mixing and stirring evenly, ferment for 7 days.

[0041] 3) The fermented mixture is mixed with the foundation pit soil at a mass ratio of 35:65, stirred evenly, and then entered into the aging warehouse for aging. The aging time is 3 days.

[0042] 4) Crush the cinder into particles of 0~3mm, and mix and stir the aged mixture and cinder at a mass ratio of 75:25;

[0043] 5) After the billet is evenly stirred, it is press-formed and the semi-hard extrusion process is used to make the billet, and the pressure is 2.7MPa;

[0044] 6) The green body enters the drying room and is dried for 3 hours at 150°C. ;

[0045] 7) Th...

Embodiment 3

[0047] A preparation method of biomass modified sludge sintered bricks, comprising the following steps:

[0048] 1) Break the sawdust and straw into 0~3mm biomass particles.

[0049] 2) The calorific value of biomass particles is 2100kcal, and the calorific value of sludge is 750kcal. The mass percentage of biomass particles and sewage sludge is 15:85. After mixing and stirring evenly, ferment for 6 days.

[0050] 3) The fermented mixture is mixed with the foundation pit soil at a mass ratio of 40:60, stirred evenly, and then entered into the aging warehouse for aging, and the aging time is 2 days.

[0051] 4) Crush the cinder into particles of 0~3mm, and mix and stir the aged mixture and cinder at a mass ratio of 80:20;

[0052] 5) After the billet is evenly stirred, it is press-formed and the semi-hard extrusion process is used to make the billet, and the pressure is 2.5MPa;

[0053] 6) The green body enters the drying room and is dried for 3 hours at 160°C. ;

[0054] 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com