Continuous metering charging system of reaction vessel

A feeding system and reactor technology, applied in feeding devices, phosphorus compounds, non-metallic elements, etc., can solve the problem of inaccurate control of reaction feeding amount, unguaranteed quality of ferric phosphate products, difficult real-time flow monitoring, etc. problems, to achieve stable quality, reduce fluctuations in readings, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

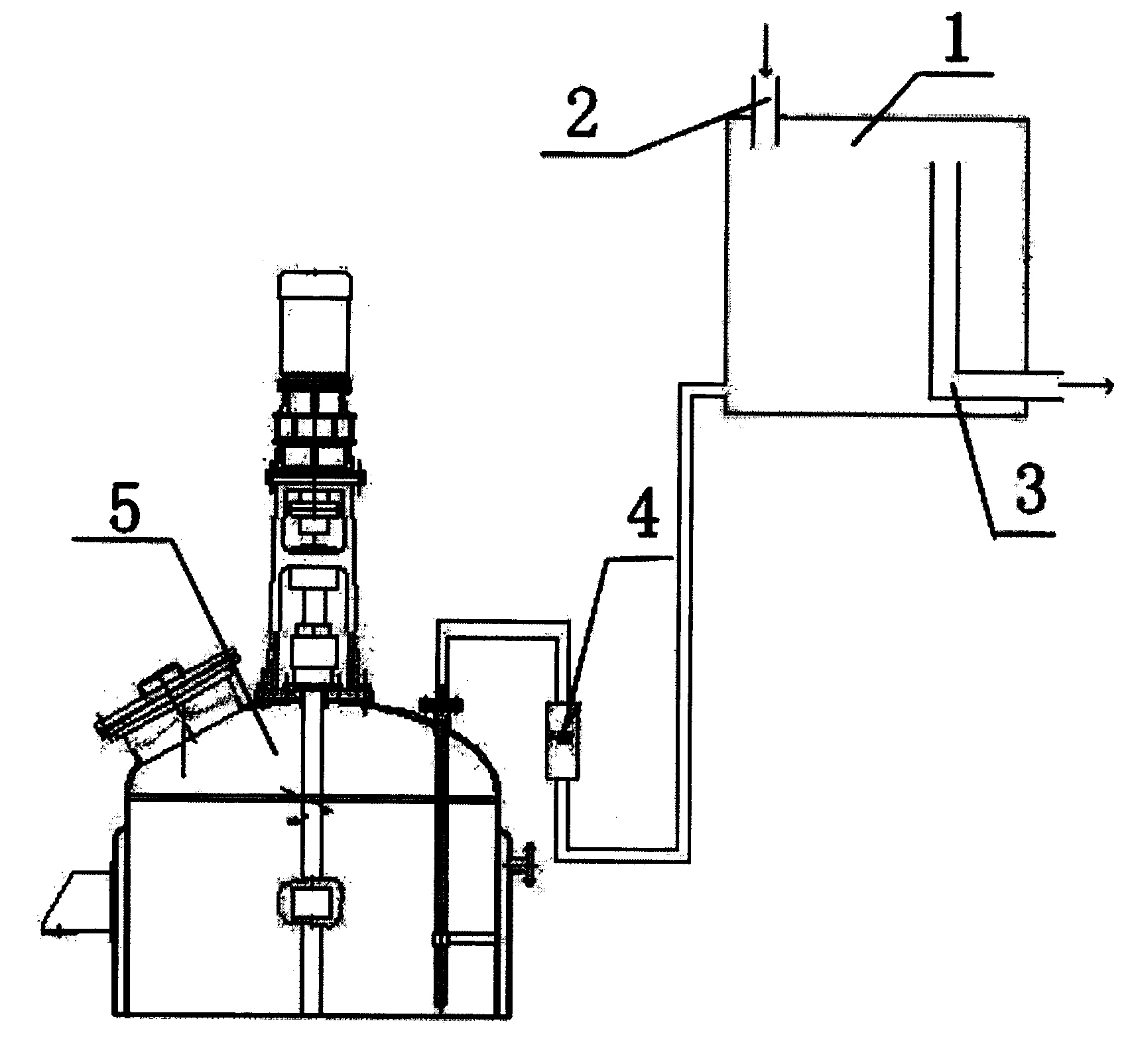

[0012] The following describes the technical solution of the present invention in detail through a best embodiment in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the embodiment.

[0013] As shown in the figure, a reactor continuous metering feeding system includes a container 1 and a flow meter 4, the container 1 is connected to the flow meter 4 through a pipeline, the container is higher than the flow meter, and the container is provided with a liquid inlet 2, The container is provided with a liquid discharge port 3 higher than the bottom surface of the container, and the liquid discharge port 3 is a part of the liquid discharge pipe arranged inside the container. The flow meter 2 is a glass rotameter, and the outlet of the flow meter 4 is connected to to Reactor 5.

[0014] Working principle: The container replenishes the reaction liquid through the liquid inlet at all times, and then the excess liquid retur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com