Pneumatic atomization system with rotatable spraying head

An atomization system, rotary atomization technology, applied in the direction of spraying device, spraying device, liquid spraying device, etc., can solve the problem of high toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: Pneumatic atomization system of space spray mode with atomizing nozzle not rotating

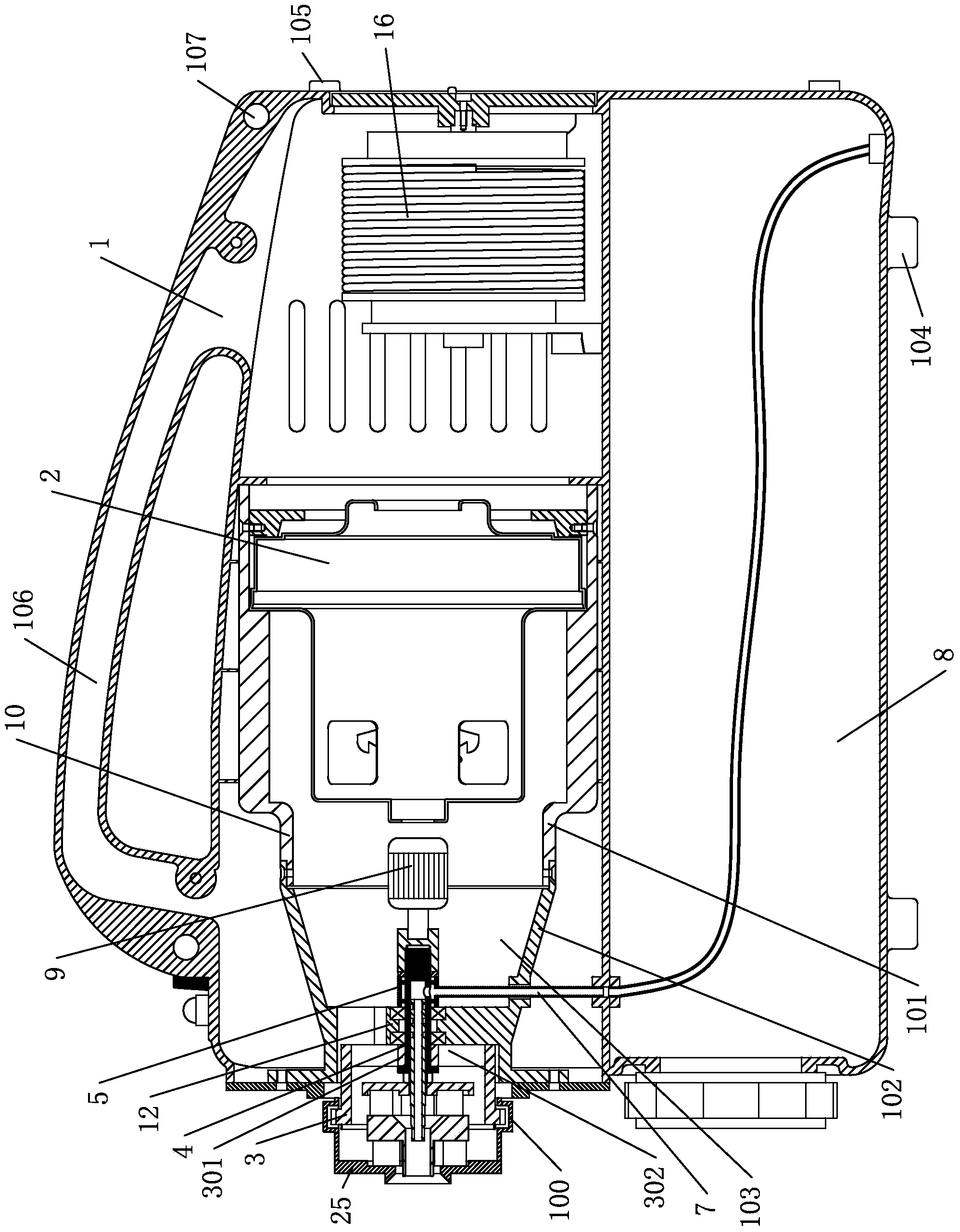

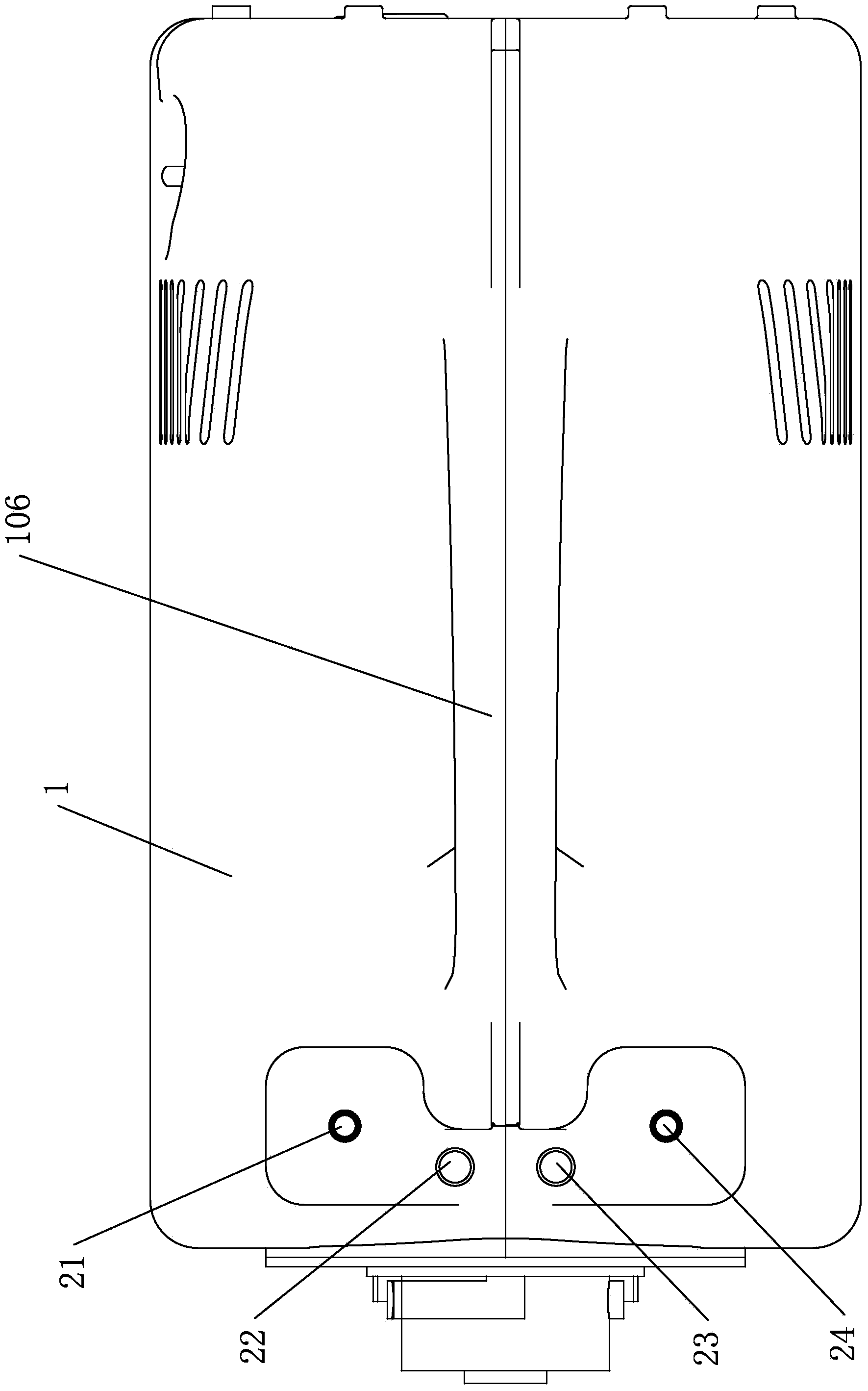

[0033] see figure 1 , 211, the pneumatic atomization system of 11, the casing 10 forming the air duct includes a rear end casing 101 and a tapered front end casing 102, the small end of the front end casing is the air duct outlet 103; the string used to generate high-speed airflow The excitation motor 2 is located in the rear end casing, and the front end of the series excitation motor 2 relative to the output shaft at the outlet of the air duct is provided with fan blades. The housing 10 is located inside the housing 1 . The upper space of the casing has a casing 10 and an automatic wire take-up device 16 . The automatic wire take-up device 16 is used to collect the power cord that provides power for the whole machine of the pneumatic atomization system.

[0034] Shell lower space is a medicine box 8. The medicine box 8 is integrated with the shell 1, and there is n...

Embodiment 2

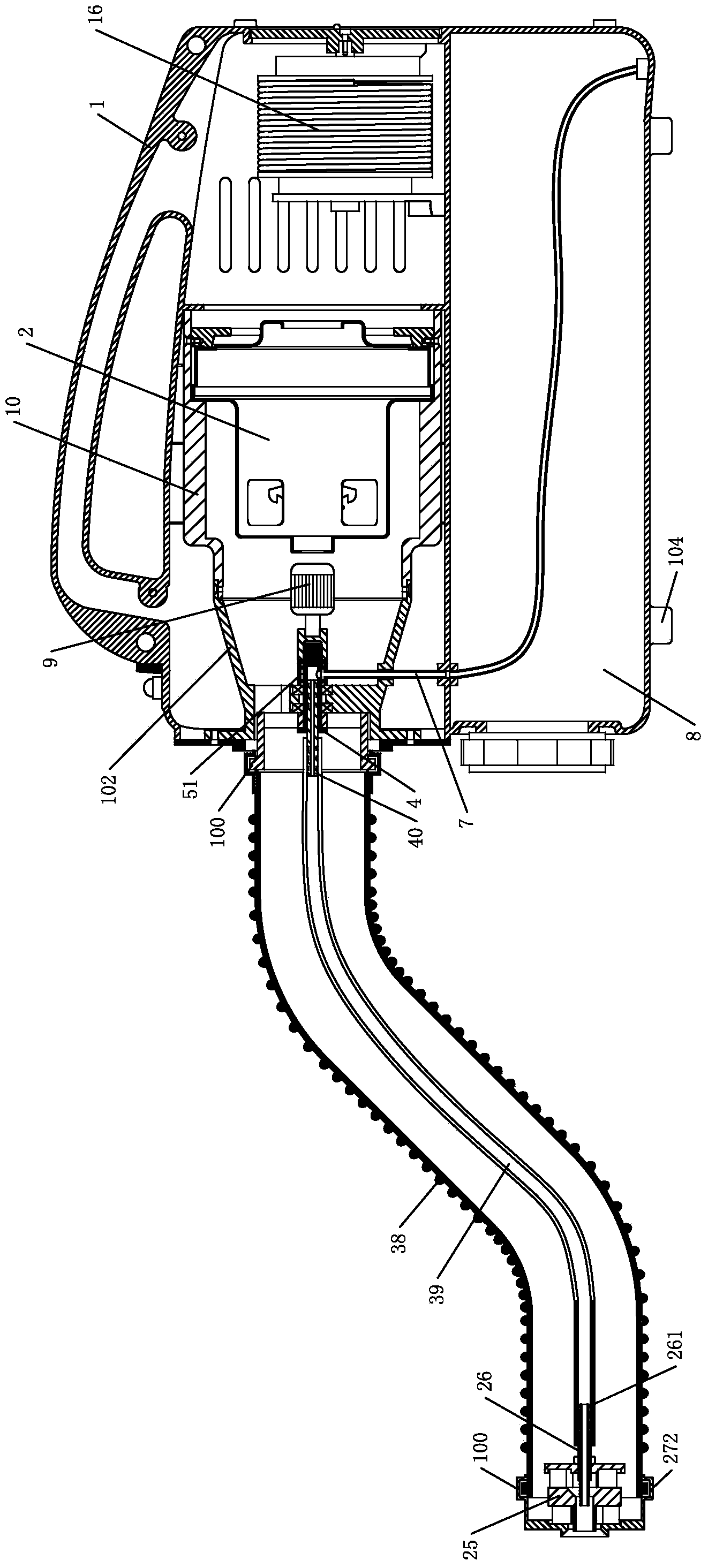

[0050] Example 2: Pneumatic atomization system of stagnant spray mode with non-rotating atomizing nozzle

[0051] see image 3 , 12 、13. For the working status of the stagnant spray when the atomizing nozzle does not rotate, refer to image 3 , the main difference between it and Embodiment 1 is that it also includes a flexible air pipe 38 and a soft liquid pipe 39, and the two ends of the flexible air pipe 38 respectively pass through the quick installation joint 100 and the rear end of the skirt 272 of the atomizing nozzle, Rotate the snap ring for a detachable connection. The air duct communicates with the air inlet channel through the rotating snap ring and the soft air pipe. Both ends of the soft liquid pipe 39 communicate with the liquid inlet end 261 of the nozzle 26 and the transition pipe 40 respectively, and the transition pipe extends into the rotating liquid collecting rod 4 and communicates with the liquid collecting channel. The liquid medicine enters the nozz...

Embodiment 3

[0053] Example 3: Pneumatic atomization system with rotating spray head in space spray mode (rotatable spray head pneumatic atomization system)

[0054] For the spatial spray state of atomizing nozzle rotation, refer to Figure 4 , 5 The main difference between it and Embodiment 1 is that it also includes a hard curved pipe 6, and the two ends of the hard curved pipe 6 are respectively connected to the rear end of the skirt 272 of the atomizing nozzle and the rotating snap ring 3 through the quick installation joint 100. Detachable connection; at the same time, when the rotating card rotates clockwise (or counterclockwise) around the axis, it can drive the hard curved pipe to rotate with the rotating snap ring, and the hard curved pipe can drive the skirt to rotate with the hard curved pipe. There are many kinds of connection structures (quick installation joints) that can be rotated clockwise (or counterclockwise) together and detachable between the hard elbow and the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com