Tube tube sheet expansion joint method

An expansion joint and pipe technology, applied in heat exchange equipment and other directions, can solve the problems of pipe end stress corrosion, repeated expansion difficulty, complex contact process, etc., and achieve the effects of improving seismic performance, uniform expansion pressure, and quick and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

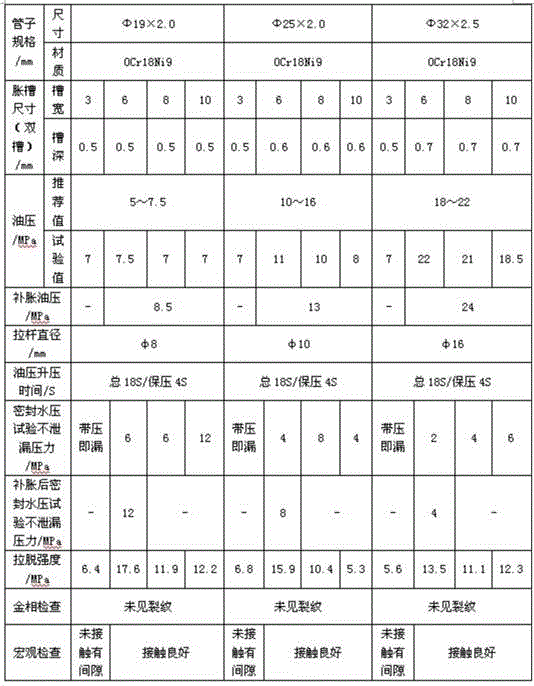

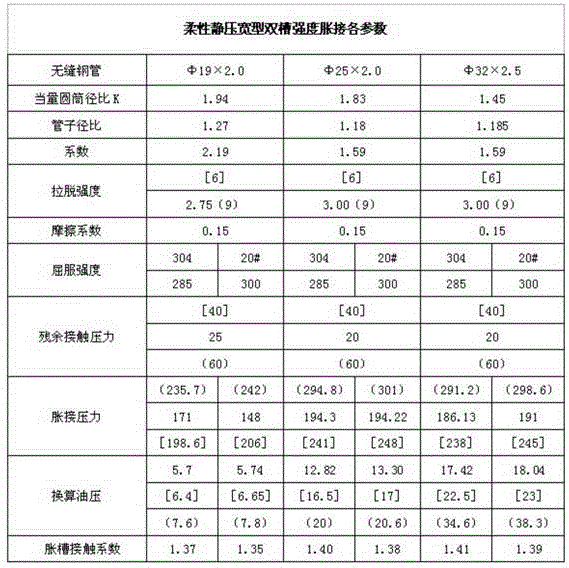

[0038] Select a tube with a size (mm) of 19×1.5 / 2.0 / 2.5, and clean the iron filings, burrs and oil stains on the tube plate holes one by one; polish the surface of the test tube to be expanded, insert the tubes into the tube plate hole from the back of the tube plate in turn, and stretch The surface of the tube plate is 3mm, and the width of the expansion groove is 10mm; the groove depth is 0.7mm.

[0039] Adjust the expansion joint oil pressure and pressure holding time, the total boost time is 20s, and the pressure holding time is 6s; adjust the expansion joint pressure, the expansion joint oil pressure is 7.5MPa. If there is no visible deformation in the expansion joint of the pipe after the rubber is withdrawn, the expansion joint pressure should be appropriately increased for supplementary expansion. The supplementary expansion oil pressure is 1MPa.

[0040] For the expansion of the tube-tube-sheet joint, after the expansion of the same specification of tubes on each tube...

Embodiment 2

[0042] Select a tube with a size (mm) of 19×1.5 / 2.0 / 2.5, and clean the iron filings, burrs and oil stains on the tube plate holes one by one; polish the surface of the test tube to be expanded, insert the tubes into the tube plate hole from the back of the tube plate in turn, and stretch The surface of the tube plate is 3mm, and the width of the expansion groove is 3mm; the groove depth is 0.5mm. Adjust the expansion joint oil pressure and pressure holding time, the total boost time is 15s, and the pressure holding time is 4s; adjust the expansion joint pressure, the expansion joint oil pressure is 5MPa. If there is no visible deformation in the expansion joint of the pipe after the rubber is withdrawn, the expansion joint pressure should be appropriately increased for supplementary expansion. The supplementary expansion oil pressure is 2.5MPa. For the expansion of the tube-tube-sheet joint, after the expansion of the same specification of tubes on each tube sheet is completed...

Embodiment 3

[0044] Select a tube with a size (mm) of 25×1.5 / 2.0 / 2.5, and clean the iron filings, burrs and oil stains on the tube plate holes one by one; polish the surface of the test tube to be expanded, insert the tubes into the tube plate hole from the back of the tube plate in turn, and stretch The surface of the tube plate is 3mm, and the width of the expansion groove is 8mm; the groove depth is 0.5mm.

[0045] Adjust the expansion joint oil pressure and pressure holding time, the total boost time is 18s, and the pressure holding time is 4s; adjust the expansion joint pressure, the expansion joint oil pressure is 15MPa. If there is no visible deformation in the expansion joint of the pipe after the rubber is withdrawn, the expansion joint pressure should be appropriately increased for supplementary expansion. The supplementary expansion oil pressure is 1MPa.

[0046] For the expansion of the tube-tube-sheet joint, after the expansion of the same specification of tubes on each tube s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com