Double-crank flying shear mechanism with instinct of automatically eliminating mechanism movement dead points

A double crank, motion technology, applied in the field of metallurgical enterprises, can solve the problems of difficult to achieve complete equality, difficult to make phases, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

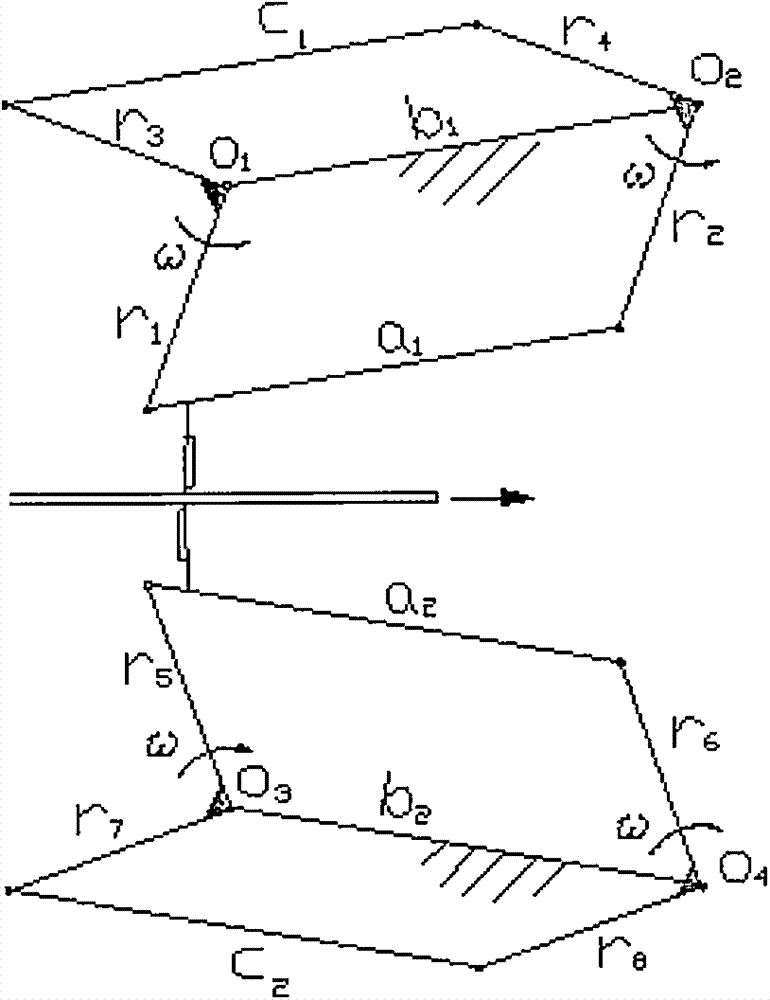

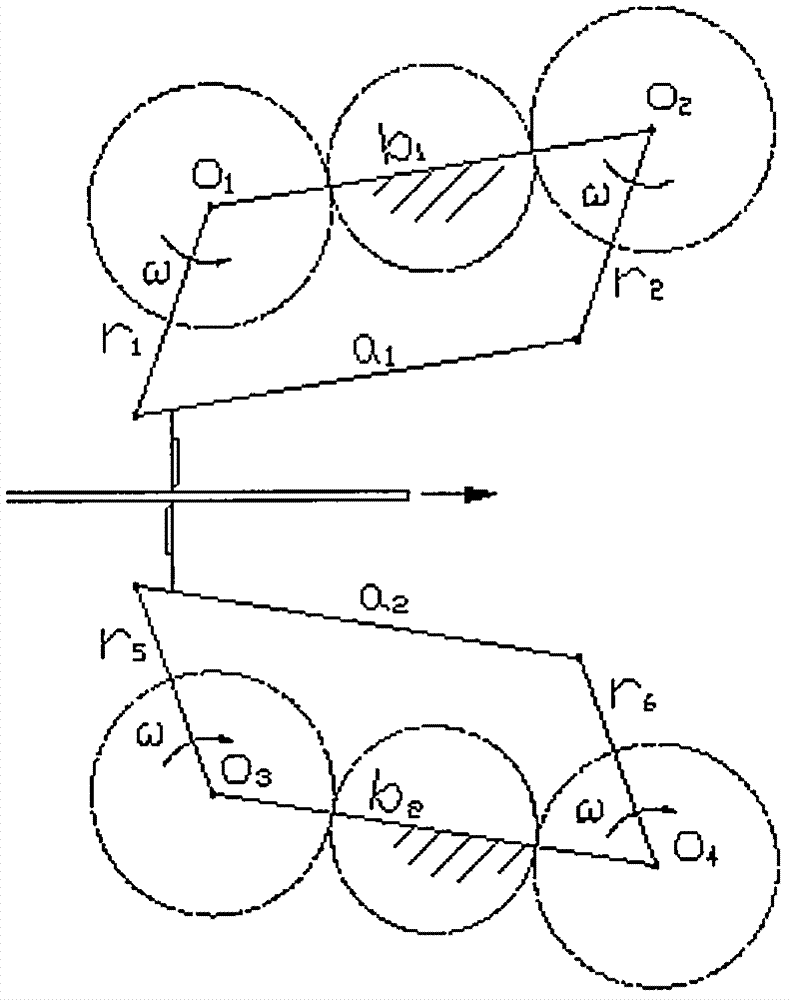

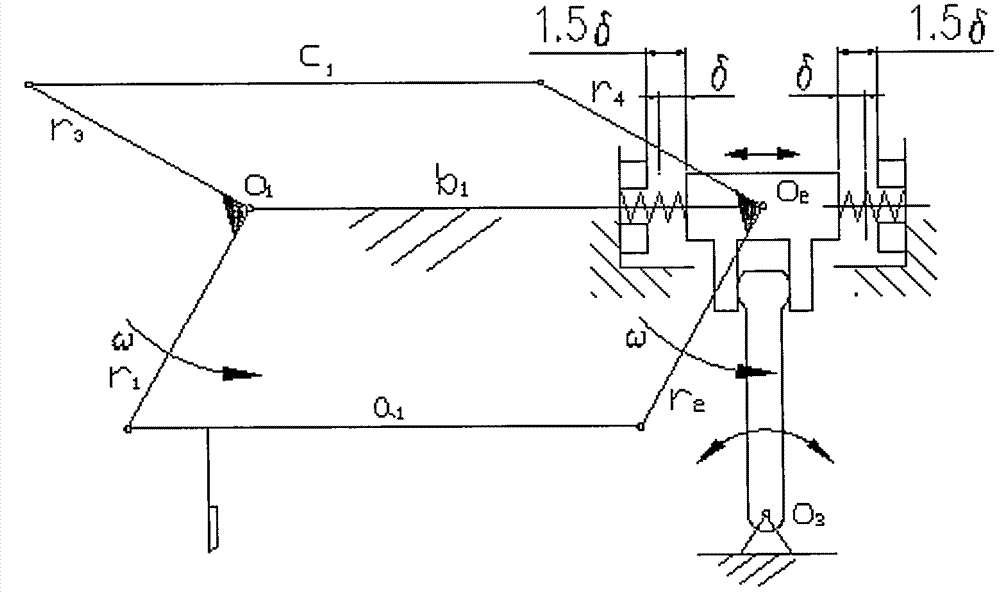

[0010] The present invention includes two sets of schemes of scheme A and B (for scheme A, see image 3 and Figure 4 ; Option B see Figure 5 and Image 6 ). Its common feature is: drive crankshaft and driven crankshaft center one of them remains stationary, and the other crankshaft center can approach or move away from that crankshaft center that remains stationary along the line connecting the two centers. Assume that the above two schemes all assume that the active crankshaft center O 1 Do not move. Support driven crankshaft O 2 There are two bearing seats in total (it can be more than two, the principle remains the same), each of them is a slider, which can automatically and synchronously approach or move away from the center of the active crankshaft from the nominal position when the mechanism reaches the dead point of motion. 1 Move a small distance δ, so that the mechanism can smoothly rush through the corresponding dead point. In order to make the above two bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com