Thermal efficiency improvement method for heating furnace and thermal efficiency improvement device for heating furnace

A technology for heating furnaces and thermal efficiency, applied in the field of thermal efficiency improvement devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1)

[0217] Nonwoven fabric made of inorganic fibers containing Si, C, O, and Zr (fiber diameter 11 μm, fiber mass per unit area 240 g / m 2 , 95% volume porosity, containing 20% by mass of rayon fibers as an example of chemical fibers, 500 mm in width, 5 mm in thickness, and 10 m in length) were cut to produce a base material of 500 mm in length and 500 mm in width. Then, the substrate is placed in a heat treatment furnace, and heat-treated at 800°C for 1 hour in an argon atmosphere to decompose and remove part of the rayon fibers contained in the substrate (nonwoven fabric) and carbonize the remaining part. , Remove the sizing agent (organic matter) applied on the substrate (the above is the first step).

[0218] Then, the heat-treated base material is entangled with two pieces of stainless steel wire mesh used as an anode electrode, and arranged on a solid solution oxide composed of Si and Zr elements selected from the first group—zircon (also called monosilicon). Zirconium aci...

experiment example 2)

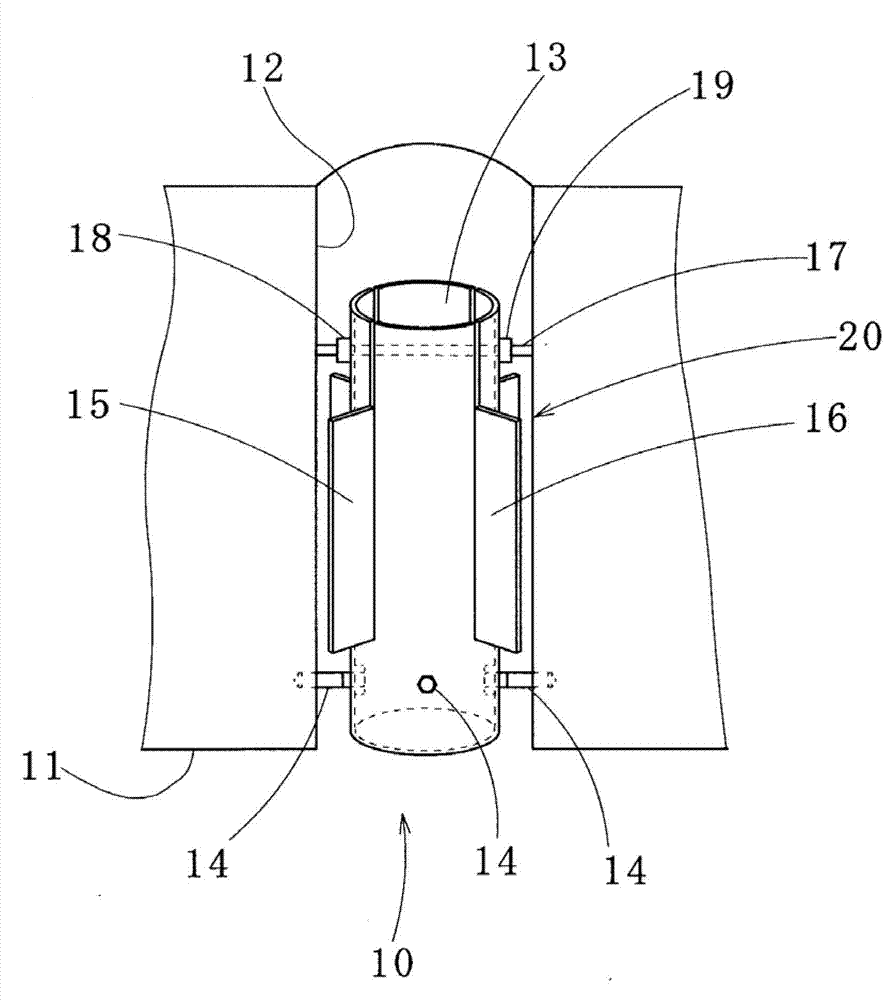

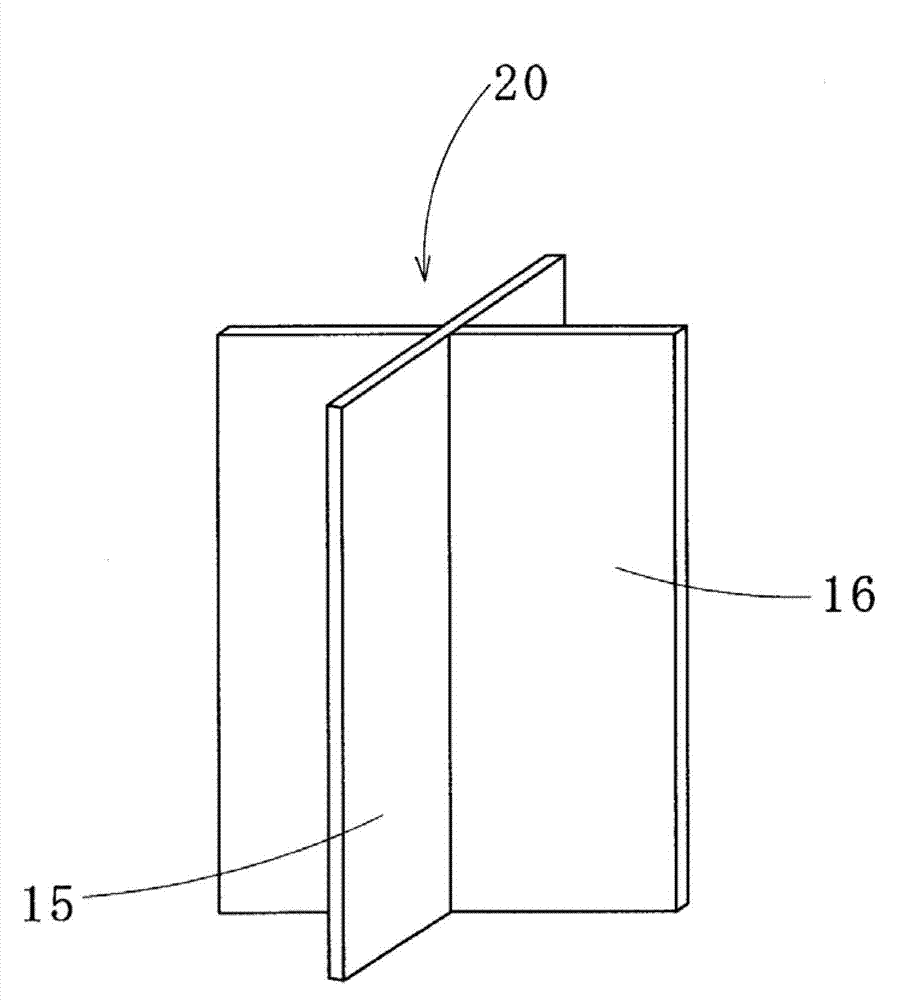

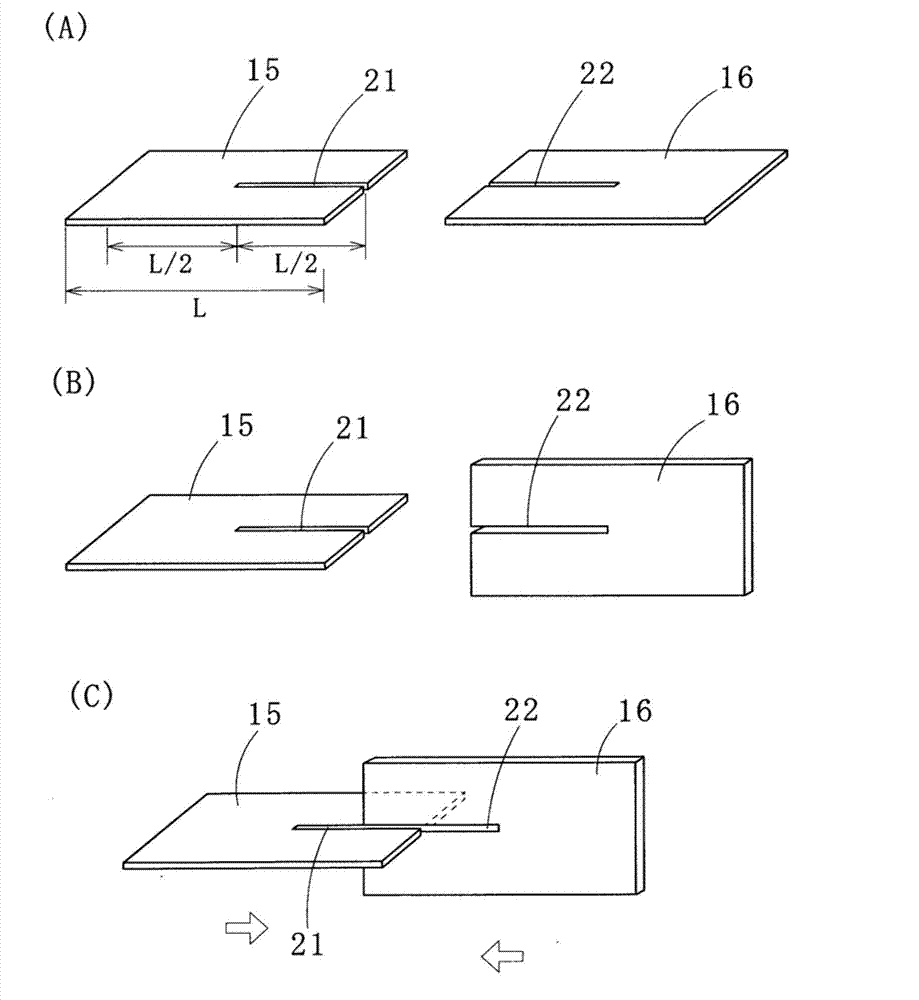

[0228] From the non-woven fabric made of composite inorganic fibers made in Experimental Example 1, cut out 2 cloth members with a length of 60 mm, a width of 130 mm, and a thickness of 5 mm. According to the same procedure as in Experimental Example 1, as Figure 16 As shown, a radial aggregate in which the minimum crossing angle between fabric members is 45 degrees is formed. In addition, if Figure 17 As shown, at the positions of 0 degrees, 45 degrees, 180 degrees and 225 degrees in the circumferential direction of the base end of the cylinder, slits are formed along the axial direction of the cylinder respectively (the length of the slit is 130mm longer than the transverse dimension of the cloth member ), at the same time, form the mounting holes for bolts made of alumina at the 4th position along the circumferential direction of the front side of the cylindrical body, and form the holes for inserting the bolts made of alumina at the opposite position of the side part of ...

experiment example 3)

[0233] Nonwoven fabric made of inorganic fibers containing Si, C, O, and Zr (fiber diameter 11 μm, fiber mass per unit area 240 g / m 2 , 95% volume porosity, 20% by mass rayon fibers, 500mm width, 5mm thickness, and 10m length roll) cutting to produce a base material with a vertical length of 500 mm and a horizontal width of 500 mm. Then, the substrate is placed in a heat treatment furnace, and heat-treated at 800°C for 1 hour in an argon atmosphere to decompose and remove part of the rayon fibers contained in the substrate (nonwoven fabric) and carbonize the remaining part. , to remove the sizing agent applied on the substrate. Next, two nonwoven fabric test pieces of 60 mm in length, 130 mm in width, and 5 mm in thickness were cut out from the base material obtained after the heat treatment. In addition, plain weave fabrics made of inorganic fibers containing Si, C, O, and Zr (mass per unit area of fibers 260 g / m 2 , opening ratio 29%, width 400mm, thickness 0.25mm, lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com