Floater vulcanizing molding method and mould for implementing method

A vulcanization molding and mold technology, which is applied to the vulcanization molding method of floats and the field of molds implementing the method, can solve the problems of surface cracking, low oil resistance stability of floats, and uneven density distribution of floats, etc., so as to improve molding efficiency and ensure drainage The effect of temperament

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

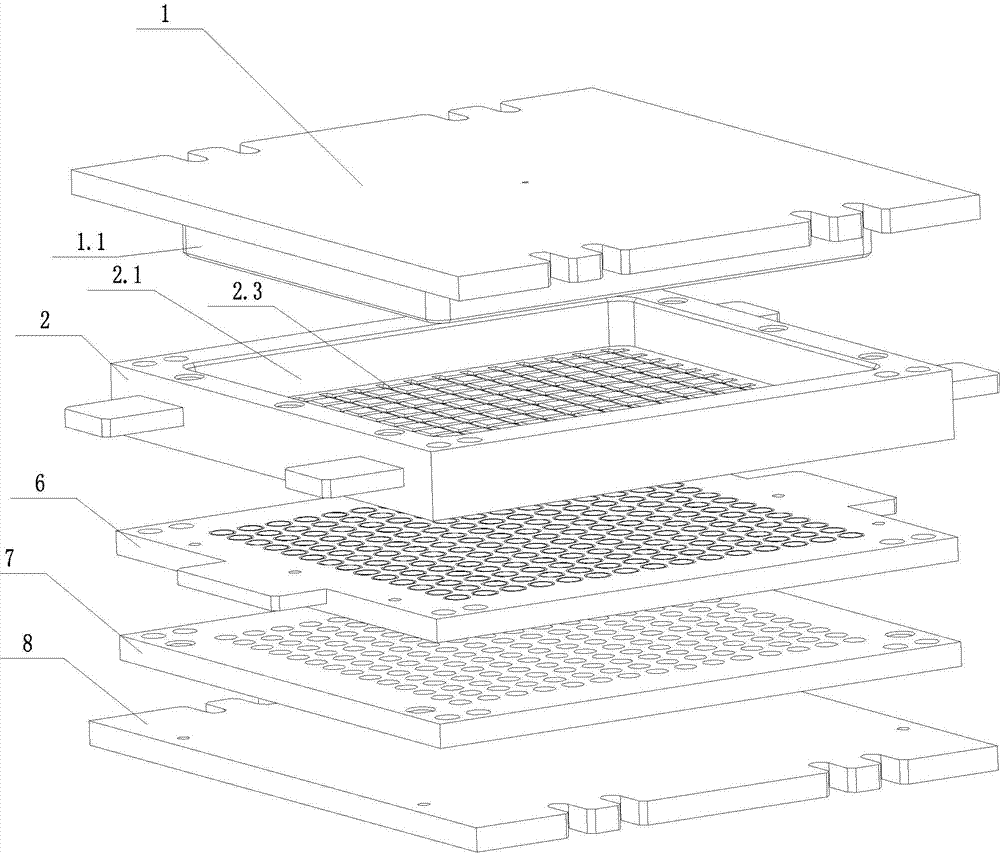

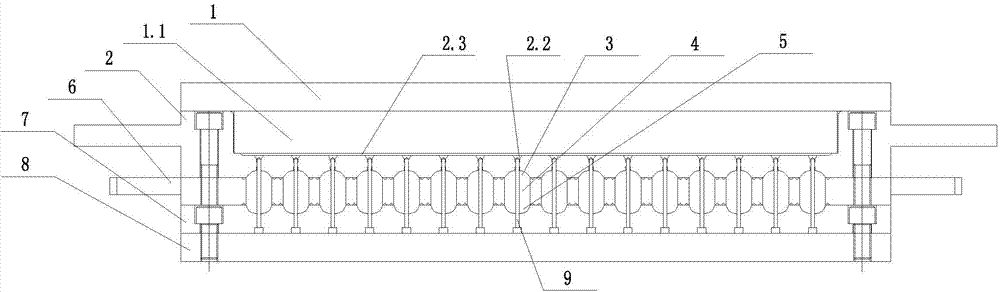

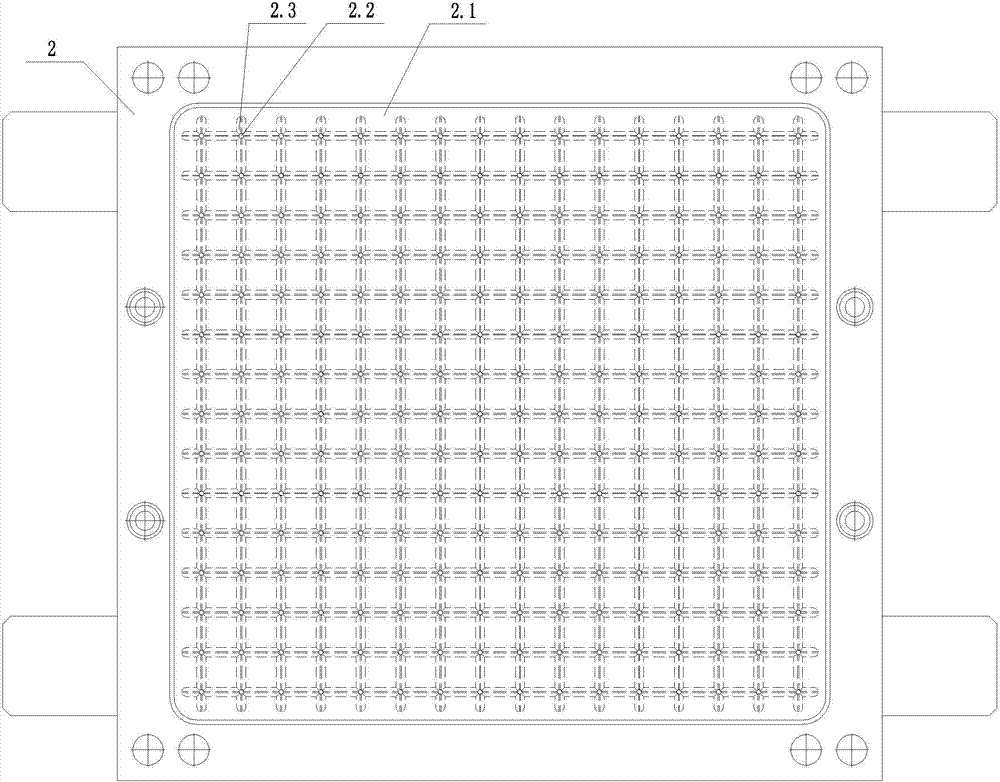

[0017] The present invention will be further described below in conjunction with accompanying drawing.

[0018] The vulcanization molding method of the floater of the present invention has the following steps: 1) Preheating the mold; 2) Putting raw materials into the mold; 3) Pressurizing the raw materials by the mold so that the raw materials melt and flow into the mold cavity. Reciprocate up and down on the pressurized template to extrude the melted raw materials to squeeze out the air; 4), the vulcanization of the float is completed, the mold is opened and the float is ejected from the mold; 5), repeat 2) to 4) to cycle Production.

[0019] The temperature of the upper mold of the mold is controlled within the range of 121°C ± 5°C, and the temperature of the lower mold of the mold is controlled within the range of 115°C ± 5°C. The upper mold of the mold is used to pressurize the raw material to melt the raw material and flow into the lower part of the mold. The mold, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com