Dust suppression and removal combined device for drop points of belt conveyors

A technology of belt conveyor and dust removal device, which is applied in the direction of conveyor objects, transportation and packaging, loading/unloading, etc., can solve the problems that are not conducive to the long-term stability of the system, the filter bag loses the filtering function, and the potential energy of the material cannot be eliminated. The effect of dust reduction is obvious, the effect of dust collection is improved, and the effect of dust removal is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

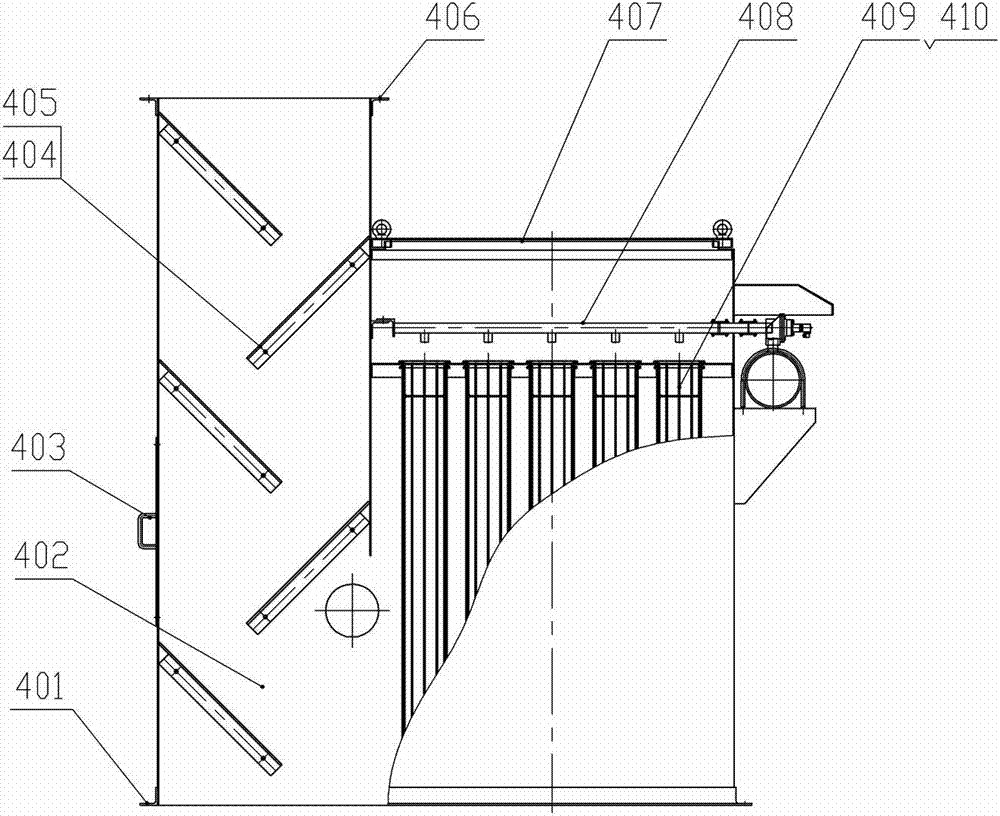

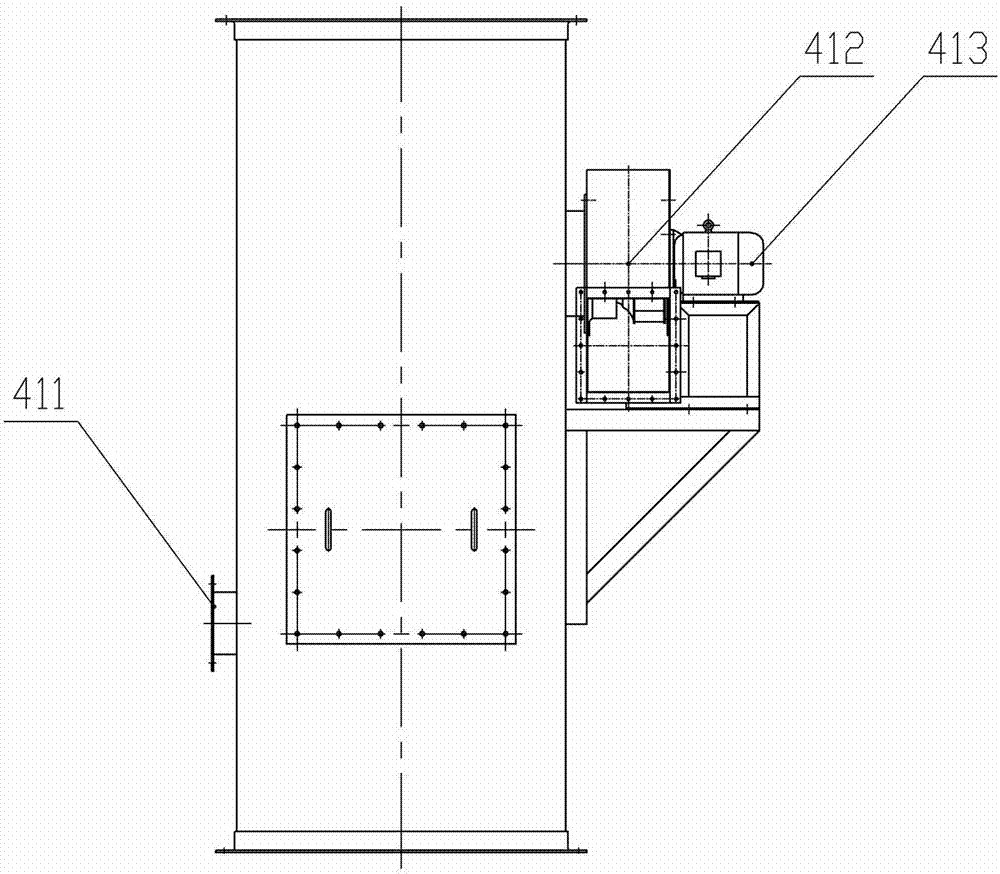

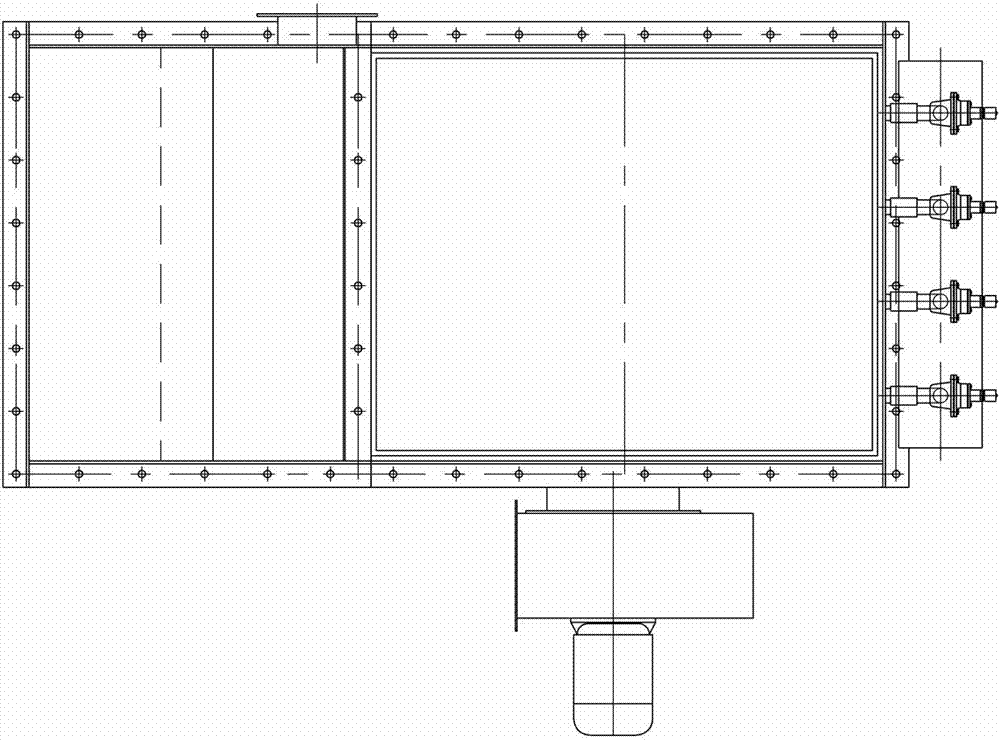

[0040] Embodiment 1, the present invention includes a box body 402, a fan 413 arranged on one side of the box body 402, and lower flanges 401 and upper flanges 406 at both ends of the box body 402, and the falling pipe and the housing of the dust collector are designed to be combined Structure, the box body 402 is divided into two parts by a partition in the middle, the blanking tube and the dust removal chamber. The wall of the blanking tube is staggered left and right or in steps, and there are more than two baffle brackets 404 that slope downward at a certain angle. A wear-resistant liner 405 is provided on the plate support 404; the upper end of the dust removal chamber is lower than the blanking pipe, and is divided into upper and lower chambers by an orifice plate. The dust removal device 408 is arranged on the upper part of the dust removal chamber. More than 2 columns and more than 2 rows of vertically parallel filter bags are arranged in the holes, which are supported ...

Embodiment 2

[0042] Embodiment 2, the present invention is installed in the unloading trough of the upper belt conveyor with a certain drop and the receiving chute of the lower belt conveyor, airtight covers are respectively arranged at the unloading chute and the receiving chute, and the upper airtight cover is provided with The dust suction branch pipe is connected with the air inlet under the cabinet. The upper end of the box body 402 is fixedly connected with the upper sealing cover 3 through the upper flange 406 , and the lower end is fixedly connected with the lower sealing cover 5 through the lower flange 401 . refer to Figure 1 to Figure 5 , all the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com