Counterweight balance equipment of crane

A counterweight balance and crane technology, applied in the direction of cranes, etc., can solve problems such as increased operating energy consumption, non-compliance, and decreased profitability of the terminal, and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

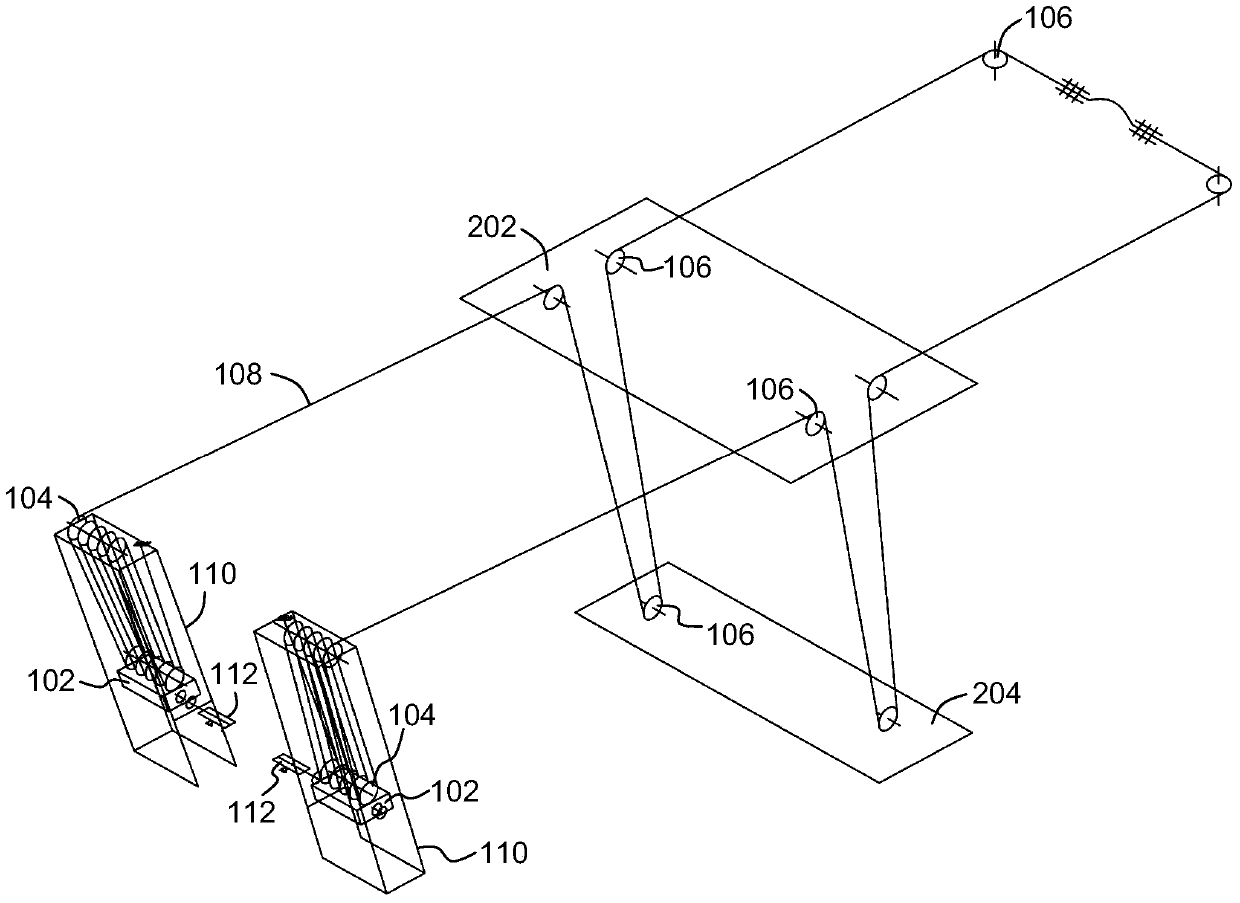

[0017] The main energy consumption of container cranes is the lifting action when lifting goods (including empty load at high speed), and the spreader mechanism will move up and down with the loading and unloading containers every time, so it also consumes a lot of energy. In the past, the energy-saving optimization of cranes mainly focused on optimizing the structure of the spreader mechanism itself, such as reducing the self-weight of the spreader and the self-weight of the rack, or using two separate racks instead of the whole rack. However, due to the limitation of the lifting capacity of the container, it is difficult to reduce the weight of the spreader and the rack to meet the strength and fatigue requirements, and it is troublesome to replace the spreader with two separate racks, and terminal users are often reluctant to use it. Taking the container quay crane as an example, the current weight of the spreader mechanism is usually between 17t and 20t, while the weight of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com