Yarn breakage trigger device

A trigger device and yarn technology, applied in textiles and papermaking, can solve the problems of manpower consumption, production loss, easy breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

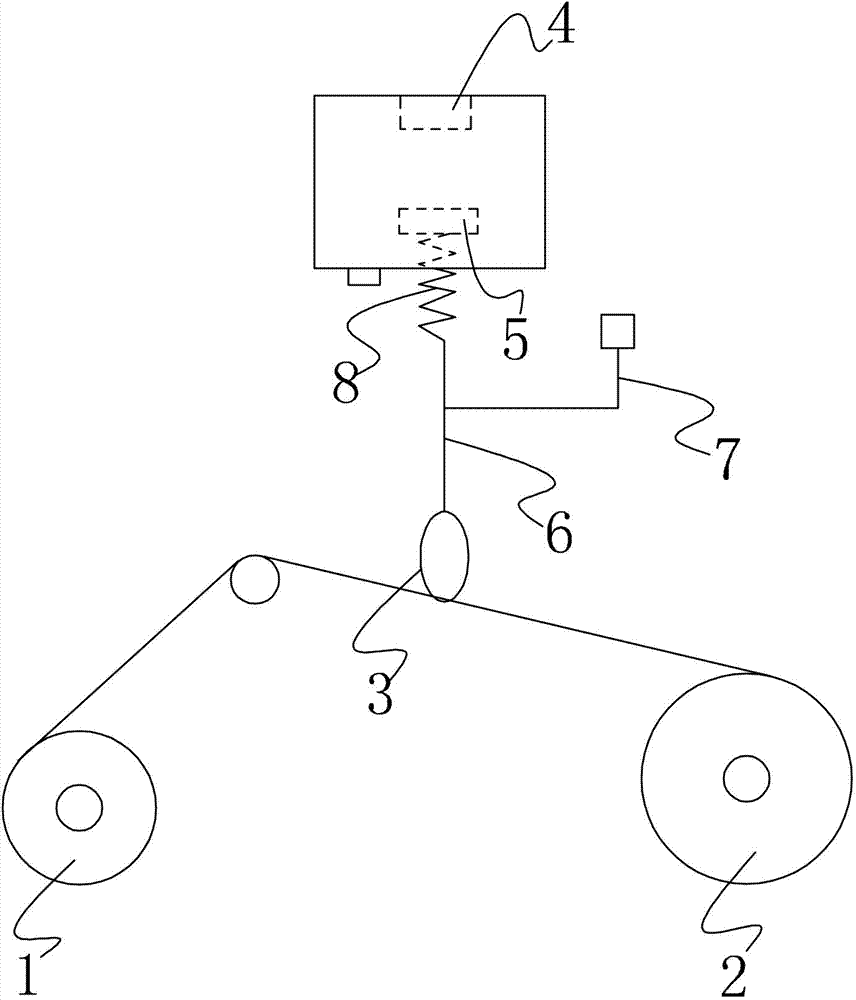

[0010] Such as figure 1 Shown: the yarn break trigger device, including the frame, the frame is set between the reel 1 and the spool 2, the reel 1 and the spool 2 are connected to the power source, the reel 1 and the spool 2 are stretched with yarn , A trigger box is installed on the frame, and a nozzle facing the lifting ring 3 is fixed on the bottom surface of the trigger box, and the nozzle is connected with a water pipe. A magnetic mother 4 is installed on the top of the trigger box, and a magnet 5 is placed on the bottom of the box. The upper end of the suspension ring 3 is fixed with a connecting rod 6, the connecting rod 6 is connected with a tension spring 8, and the tension spring 8 is inserted into the trigger box and connected with the magnet 5. The rod body of the connecting rod 6 is provided with an L-shaped impact rod 7 which is connected to the power switch ( figure 1 The power switch is not shown in the drawing) connection, and the impact rod 7 is also connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com