Construction technology of cantilever piling and supporting structure combined with sloping

A technology of support structure and construction technology, which can be applied in basic structure engineering, excavation, construction, etc., and can solve problems such as inability to slope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

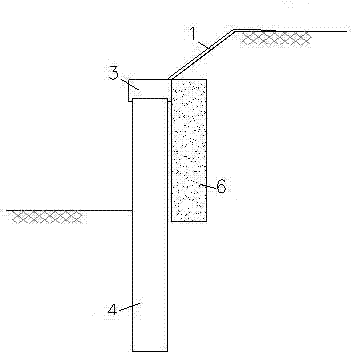

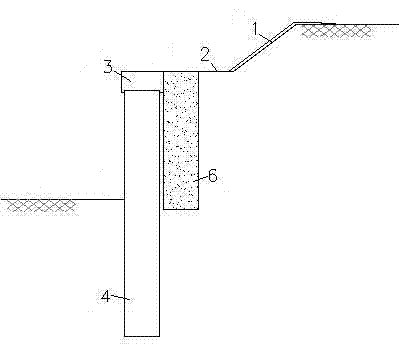

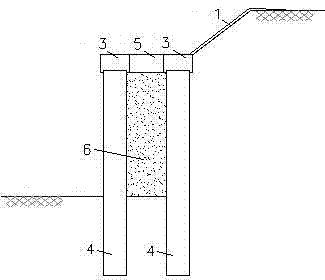

[0024] Please refer to Figure 1 to Figure 6 , the embodiment of the present invention combines the construction technology of the cantilever row pile support structure of grading, and its technological process is:

[0025] Step a), after measuring and placing the 6 pile positions of the mixing pile, drill down and spray the grout, then lift the spray grout to stir, re-drill and spray the grout to stir, repeat the lifting of the spray grout to mix, and the drilling rig will move after the pile is completed;

[0026] Step b), after measuring and laying the 4 pile positions of the supporting piles, the drilling rig equipment is in place and aligned with the center of the drilling hole to start the hole, hoist the casing into the hole, re-measure the hole position, bury the casing, and use mechanical re-measurement Put the hole posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com