Assembling method for the vibration damping structure of the shroud blades of the marine steam turbine with the external tension bars

A vibration damping structure and assembly method technology, which is applied in the direction of blade support components, mechanical equipment, engine components, etc., can solve the problems such as the reduction of the flow efficiency of the tie bars, the large amount of steam leakage, and the large gap between the group shrouds. The effect of reducing steam leakage loss, simple processing technology and improving flow efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

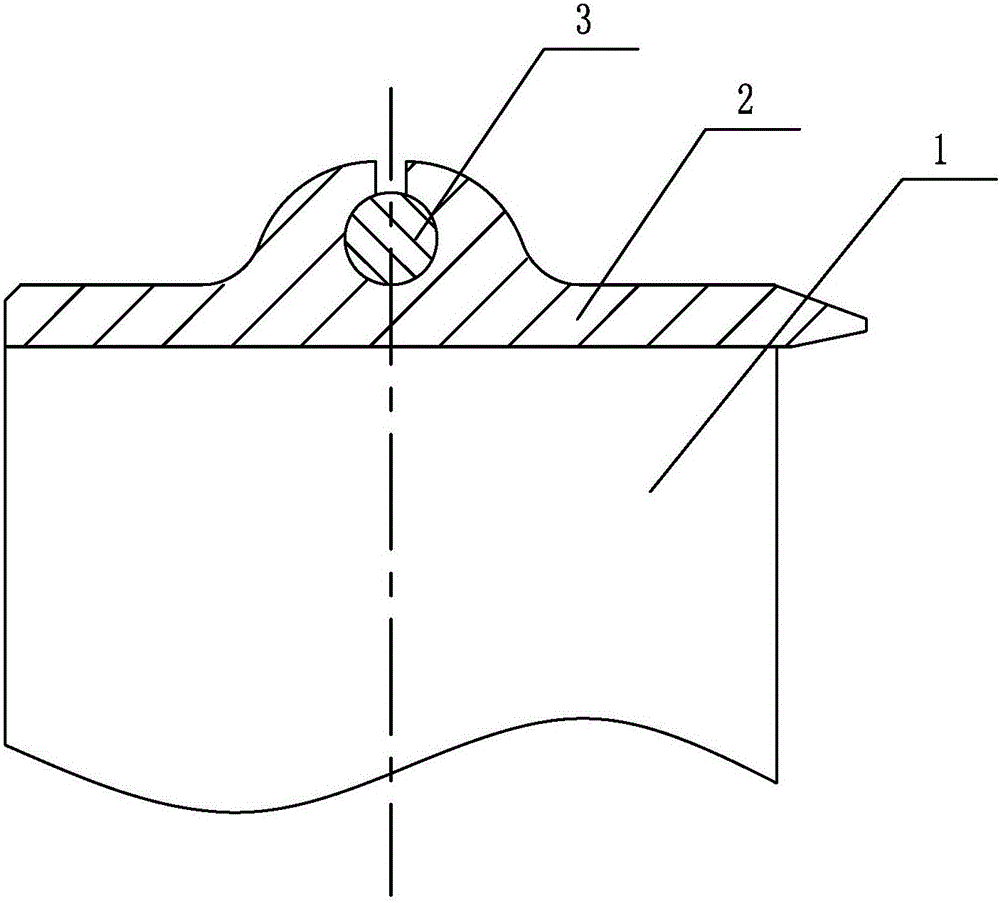

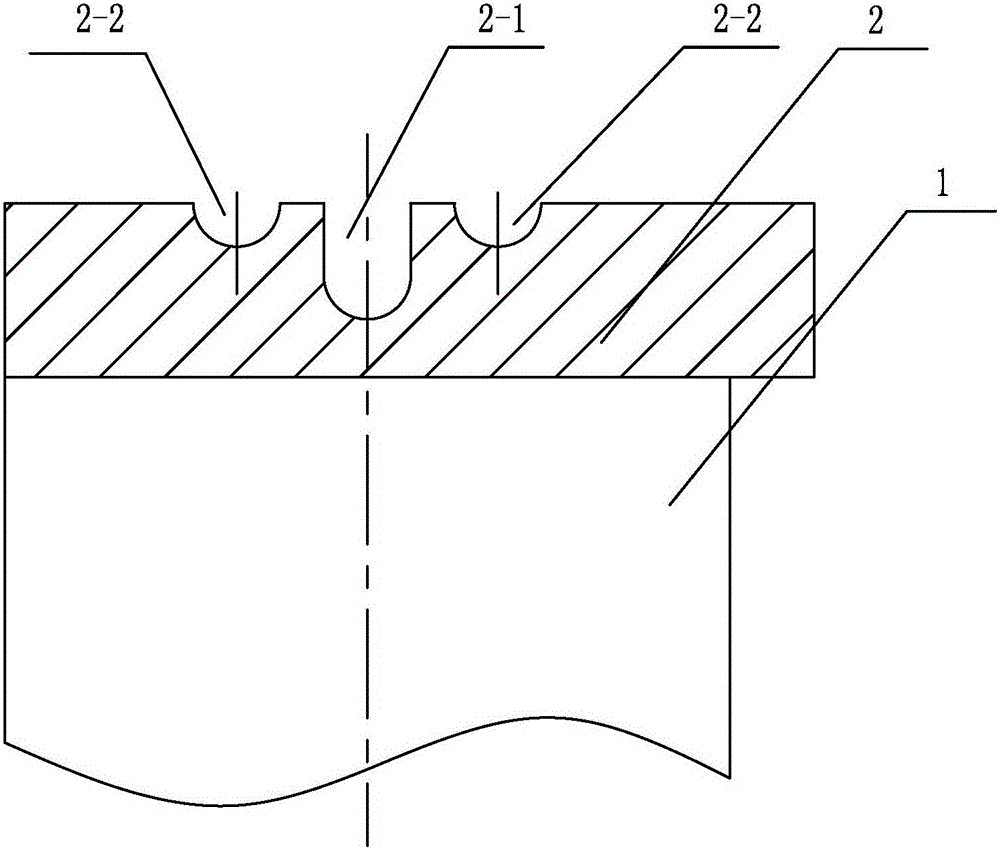

[0020] Specific implementation method: the marine steam turbine of this embodiment has its own shroud blade outsourcing tension rib vibration damping structure including blade and vibration damping tension rib 3, and the blade structure is that the top of the blade blade body 1 has a blade shroud 2 structure, and the top of the blade shroud 2 There is a mounting groove 2-1 for vibration-damping tension ribs, and the bottom of the groove 2-1 for vibration-damping tension ribs is a semicircular structure. The vibration-damping tendon 3 is installed in the vibration-damping and tendon installation groove 2-1, and the vibration-damping tendon 3 is tightened and wrapped in the vibration-damping and tendon installation groove 2-1.

[0021] Further: The groove bottom of the vibration-damping tension rib installation groove 2-1 is a semicircular structure, and the groove wall is a straight-arm structure. 3 is installed in the installation groove 2-1 of the vibration-damping ties, roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com