Thread bushing structure

A technology of inserts and threads, applied in the field of mechanical parts, can solve the problems of easy loosening of inserts and batch oil leakage, and achieve the effects of improving reliability, preventing leakage and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

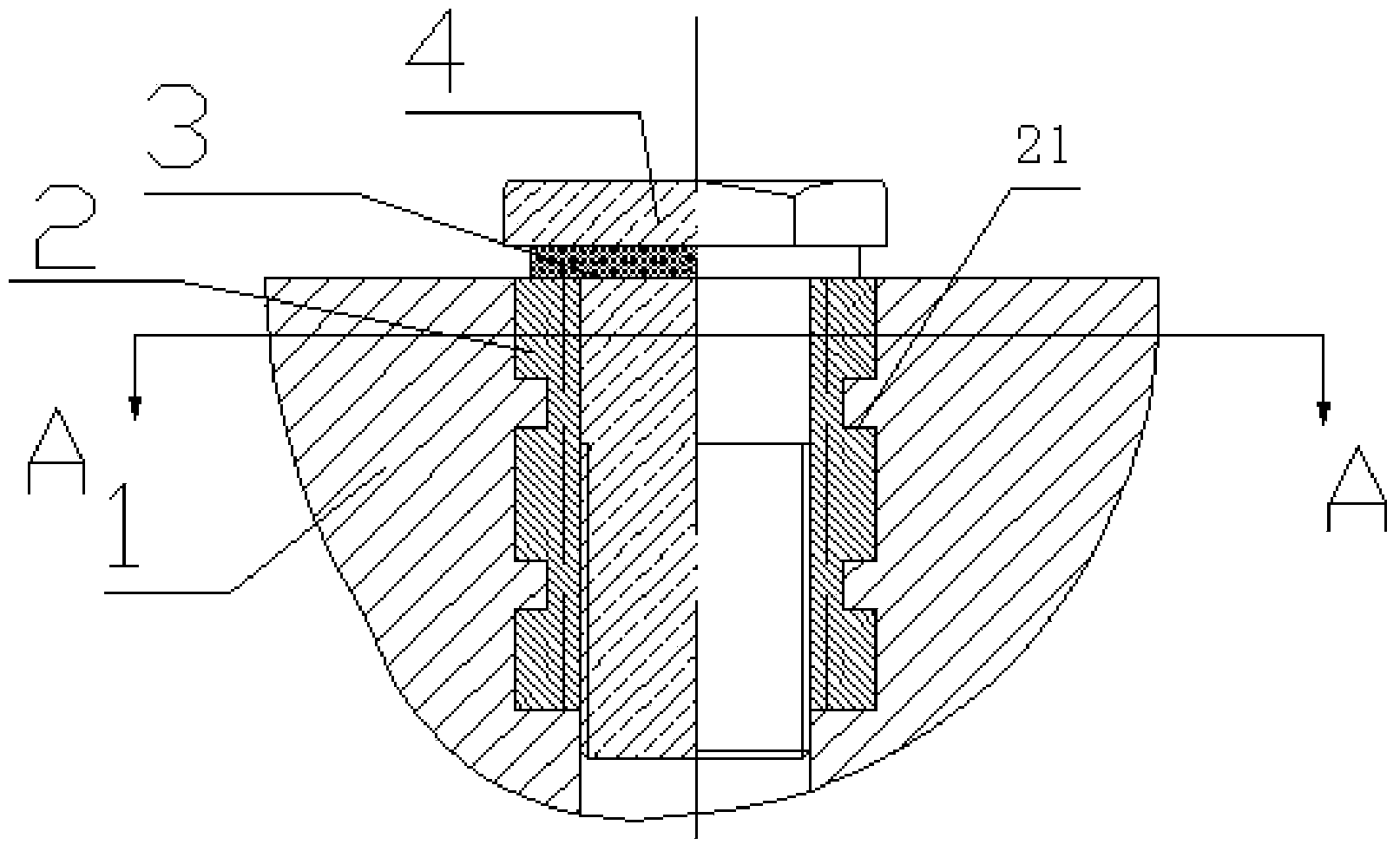

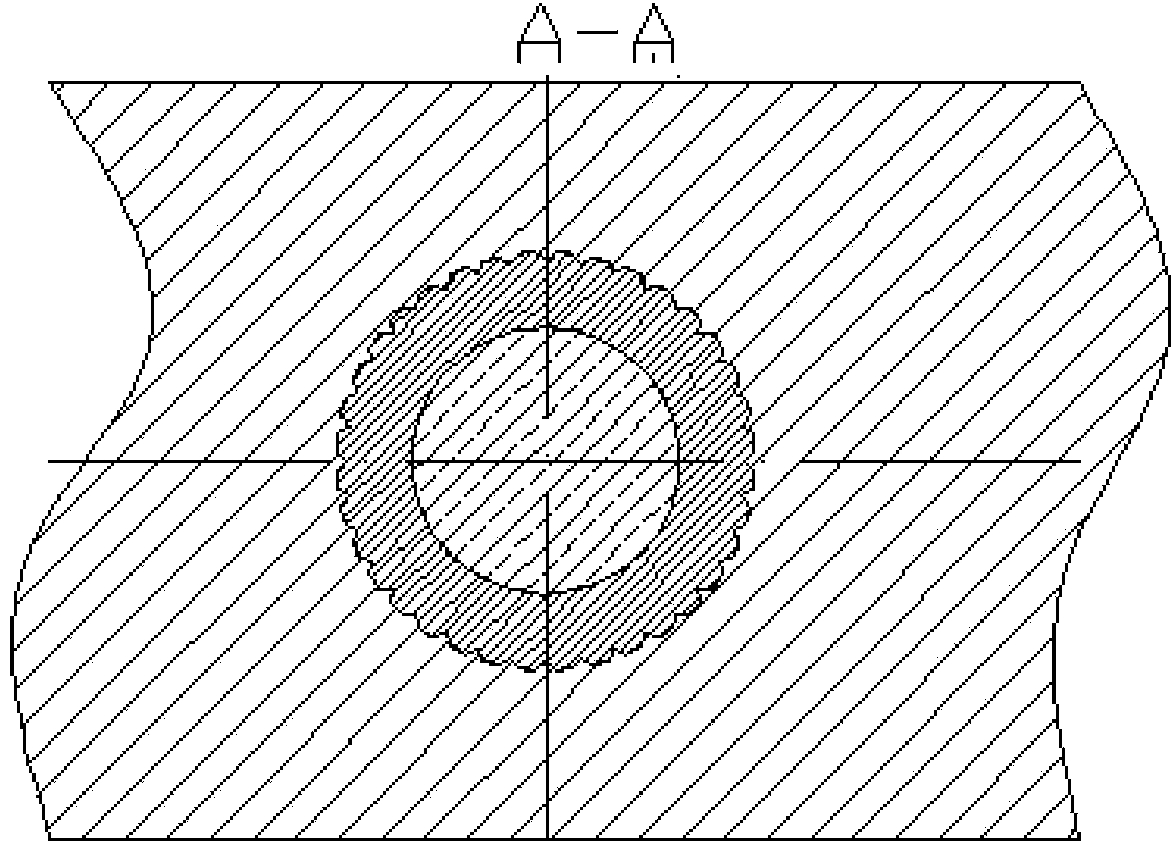

[0013] Such as figure 1 and figure 2 As shown, a threaded insert structure of the present invention is mainly designed to prevent the axial pull-out of the insert. The threaded insert structure provided in this embodiment mainly includes an insert 1 and an insert 2, and the insert 2 and the insert 1 is cast together and the insert 2 is cast inside the insert 1. The insert 2 has internal threads (not marked in the figure) for installing bolts. As a preferred embodiment, the thread insert structure also has a diameter The function of limit and axial limit ensures the reliability when the bolt is screwed into the insert 2 and the torque is tightened. In order to realize the radial limit, the outer periphery of insert 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com