Preparation method of oil-resistant and high-temperature-resistant transformer sealing element

A technology for seals and transformers, which is applied in the field of transformer parts processing, can solve problems such as damage to transformers and their working components, failure of transformer lines to supply power, and shortened service life of transformers, so as to prolong service life, delay aging phenomena, and reduce the number of failures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

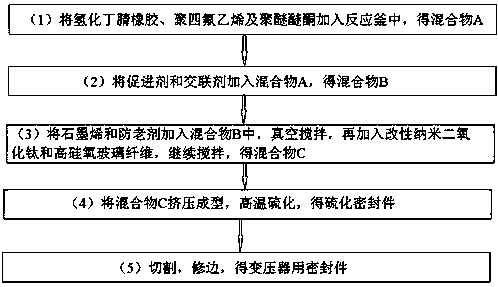

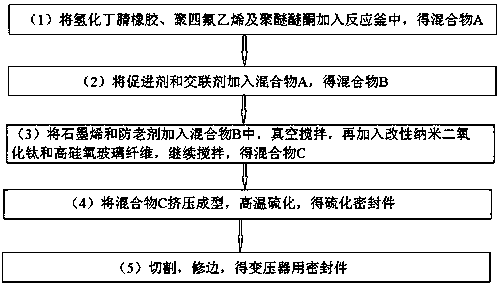

Method used

Image

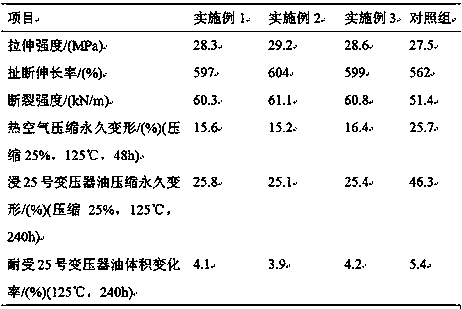

Examples

Embodiment 1

[0025] A method for preparing a seal for oil-resistant and high-temperature-resistant transformers, comprising the following steps:

[0026] (1) Add hydrogenated nitrile rubber, polytetrafluoroethylene and polyether ether ketone into the reaction kettle, add hydrogenated nitrile butadiene rubber 57, polytetrafluoroethylene 46, polyether ether ketone 33 in parts by weight, at 3°C / min Heating at a high speed until completely melted, insulated and stirred for 30 minutes, heated and stirred and fully melted, so that the raw materials are fully grafted, the strength, oil resistance and high temperature resistance of the seal are improved, and the mixture A is obtained;

[0027] (2) Add accelerator and crosslinking agent to mixture A. The amount of accelerator added is 1.5% of the weight of hydrogenated nitrile rubber, which is tetramethylthiuram disulfide, tetrabenzylthiuram disulfide, N- One or more combinations of tert-butyl-2-bisbenzothiazole sulfenamide, the amount of cross-lin...

Embodiment 2

[0032] A method for preparing a seal for oil-resistant and high-temperature-resistant transformers, comprising the following steps:

[0033] (1) Add hydrogenated nitrile rubber, polytetrafluoroethylene and polyether ether ketone into the reaction kettle, add hydrogenated nitrile butadiene rubber 58, polytetrafluoroethylene 47, polyether ether ketone 34 in parts by weight, at 3.5 ℃ / min Heating at a high speed until completely melted, insulated and stirred for 35 minutes, heated and stirred and fully melted, so that the raw materials are fully grafted, the strength, oil resistance and high temperature resistance of the seal are improved, and the mixture A is obtained;

[0034] (2) Add accelerator and crosslinking agent to mixture A. The amount of accelerator added is 1.6% of the weight of hydrogenated nitrile rubber, which is tetramethylthiuram disulfide, tetrabenzylthiuram disulfide, N- One or more combinations of tert-butyl-2-bisbenzothiazole sulfenamide, the amount of crossli...

Embodiment 3

[0039] A method for preparing a seal for oil-resistant and high-temperature-resistant transformers, comprising the following steps:

[0040] (1) Add hydrogenated nitrile rubber, polytetrafluoroethylene and polyether ether ketone into the reaction kettle, add 59 parts by weight of hydrogenated nitrile butadiene rubber, 48 polytetrafluoroethylene and 35 polyetheretherketone, at 4°C / min Heat at a high speed until completely melted, heat and stir for 40 minutes, heat and stir and fully melt, so that the raw materials are fully grafted, and the strength, oil resistance and high temperature resistance of the seal are improved, and the mixture A is obtained;

[0041] (2) Add accelerator and crosslinking agent to mixture A. The amount of accelerator added is 1.7% of the weight of hydrogenated nitrile rubber, which is tetramethylthiuram disulfide, tetrabenzylthiuram disulfide, N- One or more combinations of tert-butyl-2-bisbenzothiazole sulfenamide, the amount of cross-linking agent ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com